to Section TOC

to Master TOC

THEORY OF OPERATION

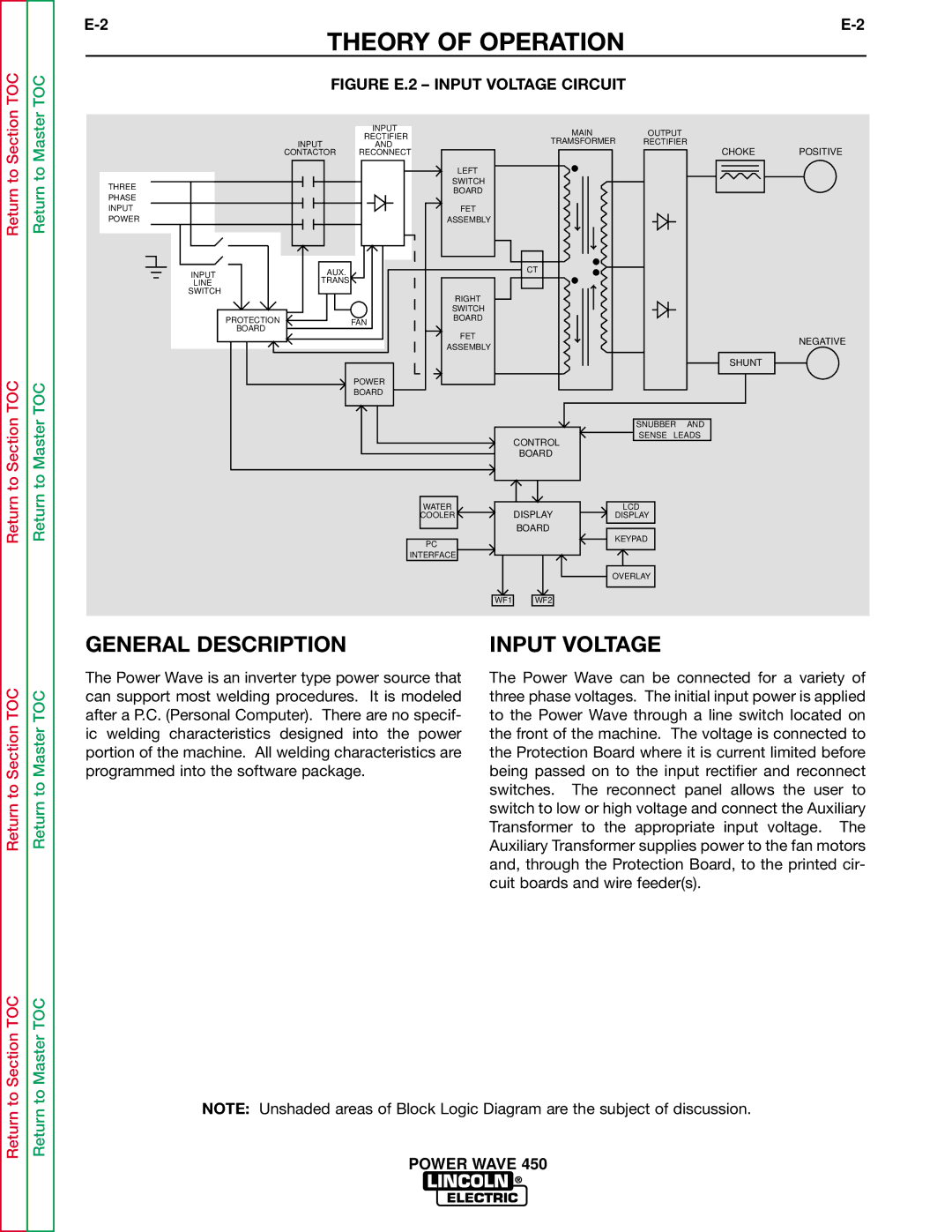

FIGURE E.2 – INPUT VOLTAGE CIRCUIT

| INPUT | MAIN | OUTPUT |

|

| RECTIFIER |

| ||

| TRAMSFORMER | RECTIFIER |

| |

INPUT | AND | POSITIVE | ||

CONTACTOR | RECONNECT |

| CHOKE | |

|

| LEFT |

|

|

THREE |

| SWITCH |

|

|

| BOARD |

|

| |

PHASE |

|

|

| |

|

|

|

|

Return

Return to Section TOC

Return

Return to Master TOC

INPUT |

| FET |

POWER |

| ASSEMBLY |

INPUT | AUX. | CT |

TRANS |

| |

LINE |

| |

SWITCH |

| RIGHT |

|

| |

|

| SWITCH |

PROTECTION | FAN | BOARD |

BOARD |

|

|

FET

ASSEMBLY

POWER

BOARD

CONTROL

BOARD

WATER

COOLERDISPLAY

BOARD

PC

INTERFACE

NEGATIVE

SHUNT

SNUBBER AND

SENSE LEADS

LCD

DISPLAY

KEYPAD

OVERLAY

WF1 WF2

Return to Section TOC

Return to Master TOC

GENERAL DESCRIPTION

The Power Wave is an inverter type power source that can support most welding procedures. It is modeled after a P.C. (Personal Computer). There are no specif- ic welding characteristics designed into the power portion of the machine. All welding characteristics are programmed into the software package.

INPUT VOLTAGE

The Power Wave can be connected for a variety of three phase voltages. The initial input power is applied to the Power Wave through a line switch located on the front of the machine. The voltage is connected to the Protection Board where it is current limited before being passed on to the input rectifier and reconnect switches. The reconnect panel allows the user to switch to low or high voltage and connect the Auxiliary Transformer to the appropriate input voltage. The Auxiliary Transformer supplies power to the fan motors and, through the Protection Board, to the printed cir- cuit boards and wire feeder(s).

Return to Section TOC

Return to Master TOC

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.