to Section TOC

to Master TOC

|

| |||

| THEORY OF OPERATION |

| ||

|

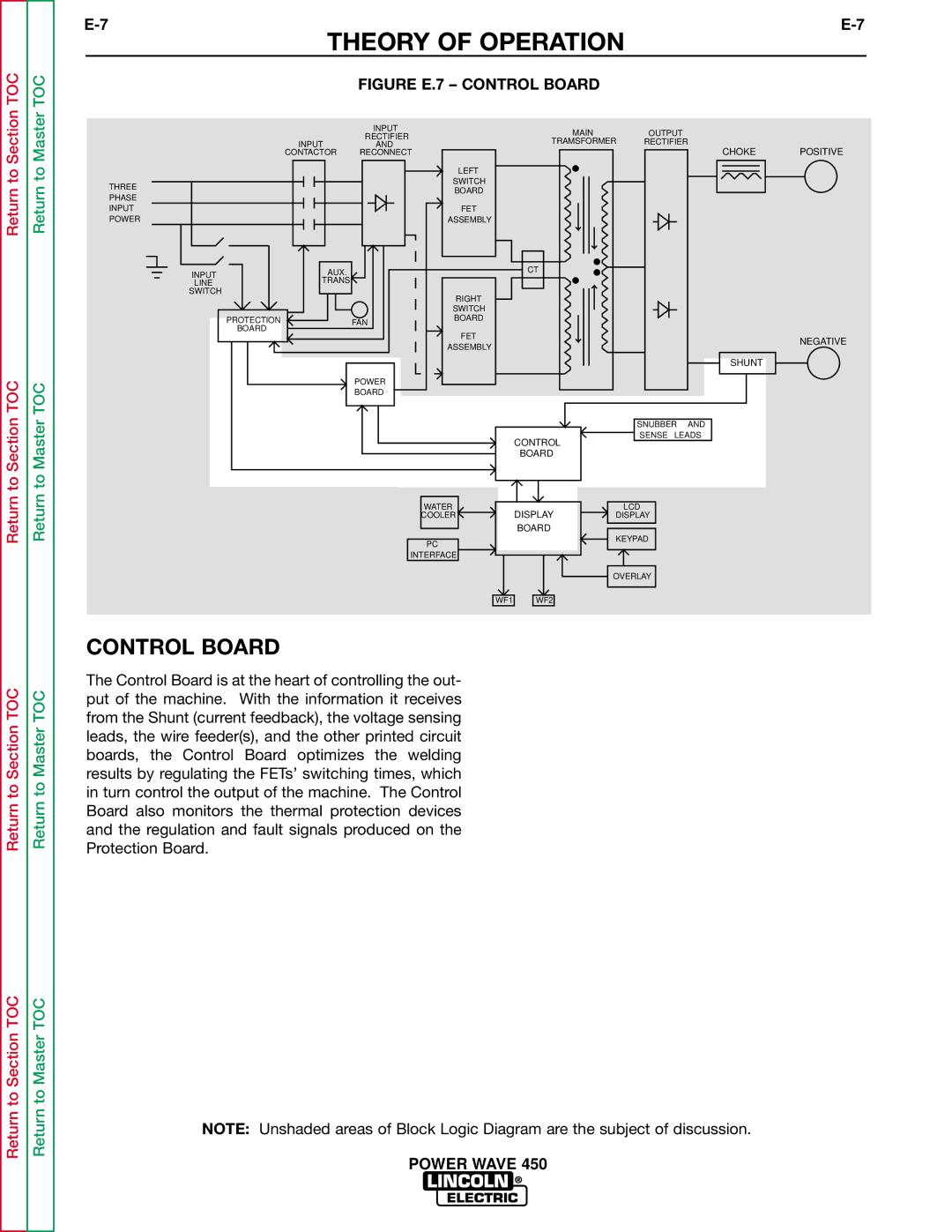

| FIGURE E.7 – CONTROL BOARD |

| |

|

| INPUT | MAIN | OUTPUT |

|

| RECTIFIER | ||

|

| TRAMSFORMER | RECTIFIER | |

| INPUT | AND | ||

| CONTACTOR | RECONNECT |

| CHOKE POSITIVE |

|

|

| LEFT |

|

| THREE |

| SWITCH |

|

|

| BOARD |

| |

| PHASE |

|

| |

|

|

|

| |

Return

Return to Section TOC

Return

Return to Master TOC

INPUT |

| FET |

POWER |

| ASSEMBLY |

INPUT | AUX. | CT |

TRANS |

| |

LINE |

| |

SWITCH |

| RIGHT |

|

| |

|

| SWITCH |

PROTECTION | FAN | BOARD |

BOARD |

|

|

FET

ASSEMBLY

POWER

BOARD

CONTROL

BOARD

WATER

COOLERDISPLAY

BOARD

PC

INTERFACE

NEGATIVE

SHUNT

SNUBBER AND

SENSE LEADS

LCD

DISPLAY

KEYPAD

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OVERLAY

WF1 WF2

CONTROL BOARD

The Control Board is at the heart of controlling the out- put of the machine. With the information it receives from the Shunt (current feedback), the voltage sensing leads, the wire feeder(s), and the other printed circuit boards, the Control Board optimizes the welding results by regulating the FETs’ switching times, which in turn control the output of the machine. The Control Board also monitors the thermal protection devices and the regulation and fault signals produced on the Protection Board.

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.