ACCESSORIES

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

OPTIONS/ACCESSORIES

•Synergic 7 wire feeder

•MAGNUM 400 gun

•Internal water cooler

•Undercarriages (Single

•Remote control (stick welding)

•Amptrols (Hand

•Limits Overlay

•Dual Wire Feeders, Dual Procedures Overlay

•Dual Feeder, Dual Procedure, Memory Selection Overlay

•Test and Calibration Overlay

WIRE FEEDER SETUP

The Power Wave must be used with wire feeders list- ed above. Mount the feeder in a location suitable to your needs.

For most applications, connect the electrode cable between the feeder and the positive (+) connection of the power source. When negative electrode polarity is required, such as in some Innershield™ applications, connect the electrode cable between the feeder and the negative

Connect the control cable between the feeder and power source. The cable has different connectors on each end and will fit in only one way. If only one feed- er is used, it must be connected to the Feeder 1 Amphenol located on the back panel in the upper left- hand corner (as you view the machine from the back). If a second feeder is used, it must be plugged into the Feeder 2 Amphenol receptacle located just to the right of the Feeder 1 Amphenol receptacle.

Connect the work cable between the work and the negative

•Connect the feeder to a welding gas supply.

•Load the wire into the feeder and gun.

•Configure wire feeders (Refer to Setup overlay in operation section.

GUNS AND CABLES

Several MAGNUM guns are recommended for use with the Power Wave as shown in Table C.1.

Place the proper liner in the gun and connect the gun to the feeder. Consult the specific instructions sup- plied with the gun for detailed operating instructions.

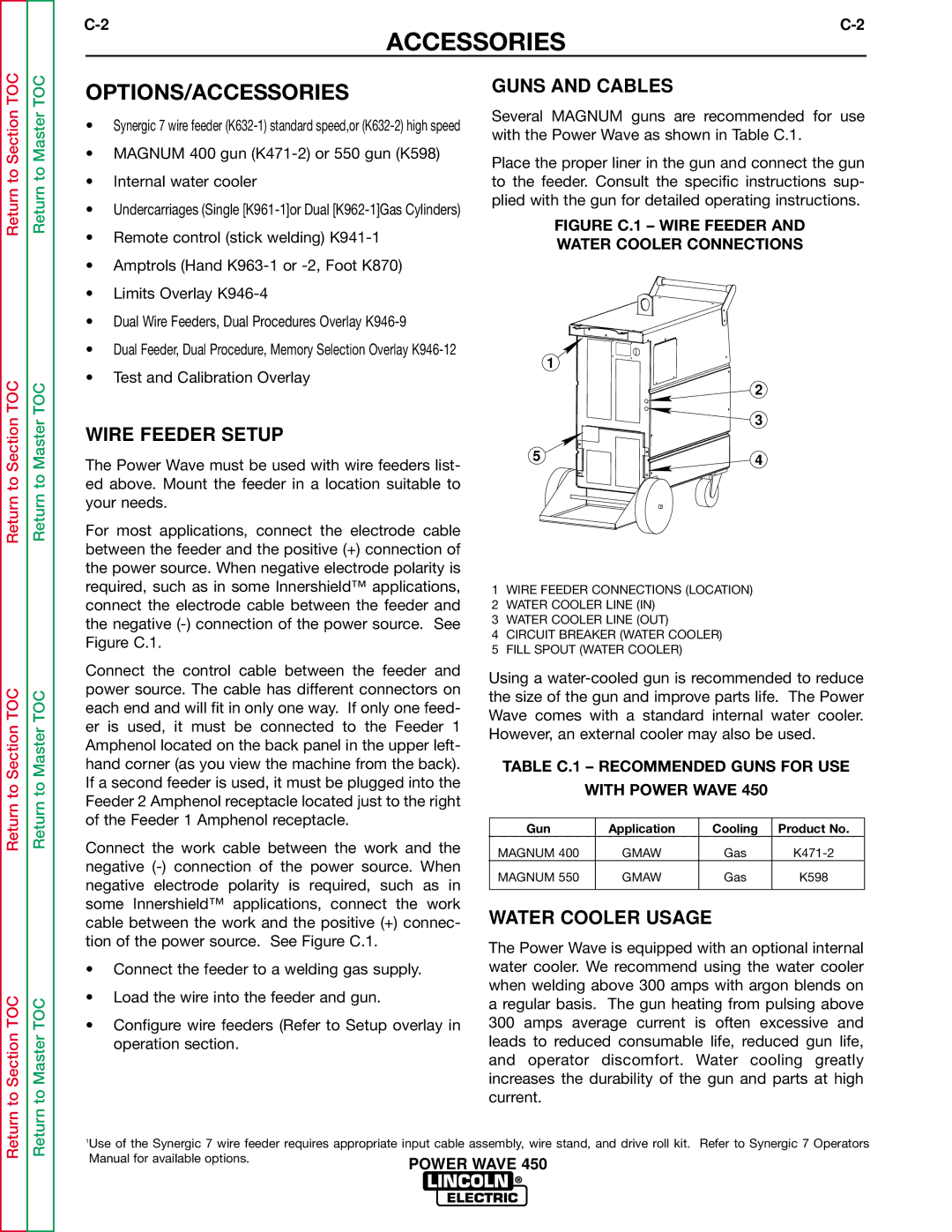

FIGURE C.1 – WIRE FEEDER AND

WATER COOLER CONNECTIONS

1

2

3

5 | 4 |

1WIRE FEEDER CONNECTIONS (LOCATION)

2WATER COOLER LINE (IN)

3WATER COOLER LINE (OUT)

4CIRCUIT BREAKER (WATER COOLER)

5FILL SPOUT (WATER COOLER)

Using a

TABLE C.1 – RECOMMENDED GUNS FOR USE

WITH POWER WAVE 450

Gun | Application | Cooling | Product No. |

MAGNUM 400 | GMAW | Gas | |

MAGNUM 550 | GMAW | Gas | K598 |

|

|

|

|

WATER COOLER USAGE

The Power Wave is equipped with an optional internal water cooler. We recommend using the water cooler when welding above 300 amps with argon blends on a regular basis. The gun heating from pulsing above 300 amps average current is often excessive and leads to reduced consumable life, reduced gun life, and operator discomfort. Water cooling greatly increases the durability of the gun and parts at high current.

1Use of the Synergic 7 wire feeder requires appropriate input cable assembly, wire stand, and drive roll kit. Refer to Synergic 7 Operators Manual for available options.