Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

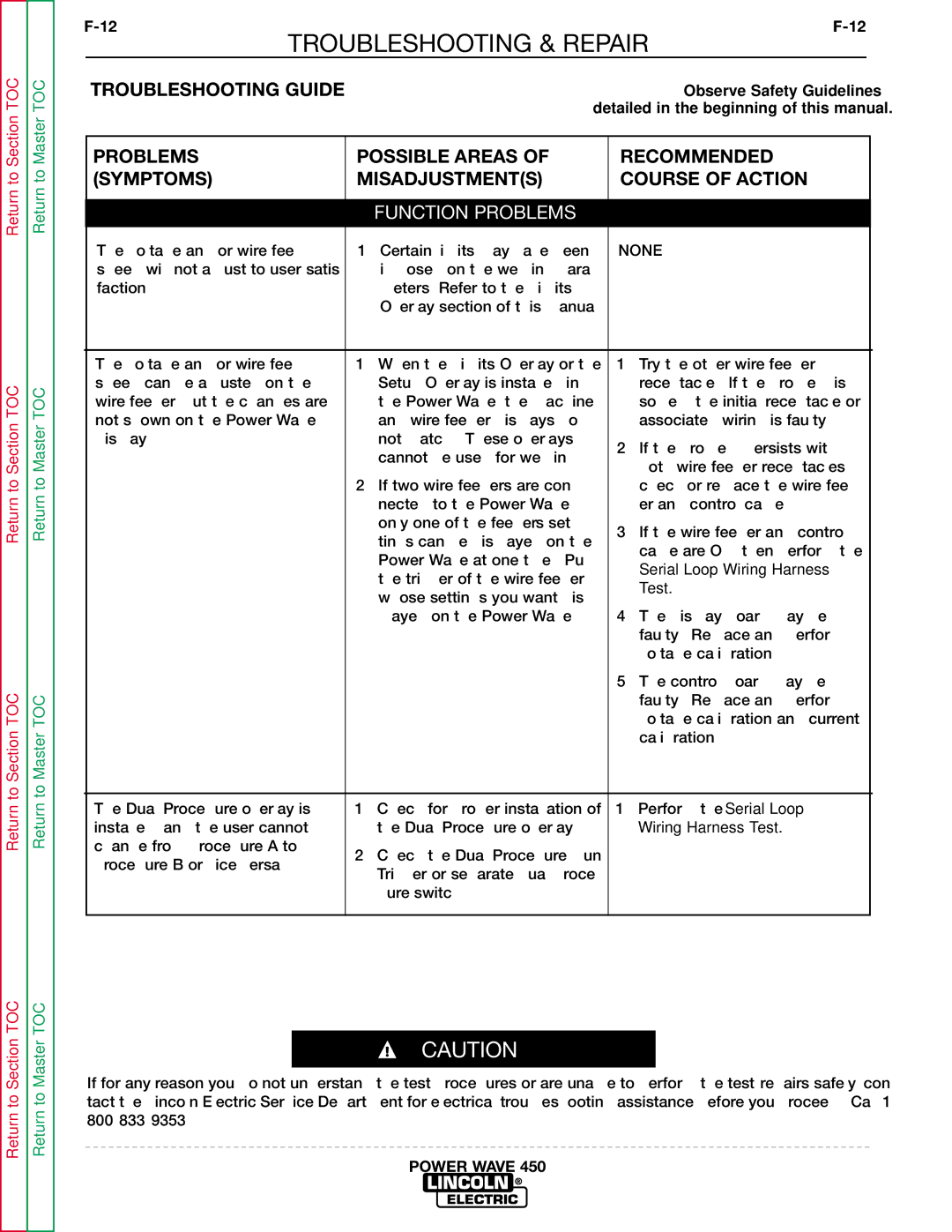

| TROUBLESHOOTING & REPAIR |

| |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| ||

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

| ||

|

|

|

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

|

| The voltage and or wire feed | 1. | Certain limits may have been | NONE |

| |

| speed will not adjust to user satis- |

| imposed on the welding para- |

|

|

|

| faction. |

| meters. Refer to the Limits |

|

|

|

|

|

| Overlay section of this manual. |

|

|

|

|

|

|

|

|

|

|

| The voltage and or wire feed | 1. | When the Limits Overlay or the | 1. | Try the other wire feeder |

|

| speed can be adjusted on the |

| Setup Overlay is installed in |

| receptacle. If the problem is |

|

| wire feeder, but the changes are |

| the Power Wave, the machine |

| solved, the initial receptacle or |

|

| not shown on the Power Wave |

| and wire feeder displays do |

| associated wiring is faulty. |

|

| display. |

| not match. These overlays | 2. If the problem persists with |

| |

|

|

| cannot be used for welding. |

| ||

|

|

|

| both wire feeder receptacles, |

| |

|

|

|

|

|

| |

|

| 2. | If two wire feeders are con- |

| check or replace the wire feed- |

|

|

|

| nected to the Power Wave, |

| er and control cable. |

|

|

|

| only one of the feeder’s set- | 3. If the wire feeder and control |

| |

|

|

| tings can be displayed on the |

| ||

|

|

|

| cable are OK, then perform the |

| |

|

|

| Power Wave at one tme. Pull |

|

| |

|

|

|

| Serial Loop Wiring Harness |

| |

|

|

| the trigger of the wire feeder |

|

| |

|

|

|

| Test. |

| |

|

|

| whose settings you want dis- |

|

| |

|

|

|

|

|

| |

|

|

| played on the Power Wave. | 4. | The display board may be |

|

|

|

|

|

| faulty. Replace and perform |

|

|

|

|

|

| voltage calibration. |

|

|

|

|

| 5. The control board may be |

| |

|

|

|

|

| faulty. Replace and perform |

|

|

|

|

|

| voltage calibration and current |

|

|

|

|

|

| calibration. |

|

|

|

|

|

|

|

|

| The Dual Procedure overlay is | 1. | Check for proper installation of | 1. | Perform the Serial Loop |

|

| installed, and the user cannot |

| the Dual Procedure overlay. |

| Wiring Harness Test. |

|

| change from procedure “A” to | 2. Check the Dual Procedure Gun |

|

|

| |

| procedure “B” or vice versa. |

|

|

| ||

|

| Trigger or separate dual proce- |

|

|

| |

|

|

|

|

|

| |

|

|

| dure switch. |

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-