INSTALLING THE UPS SYSTEM

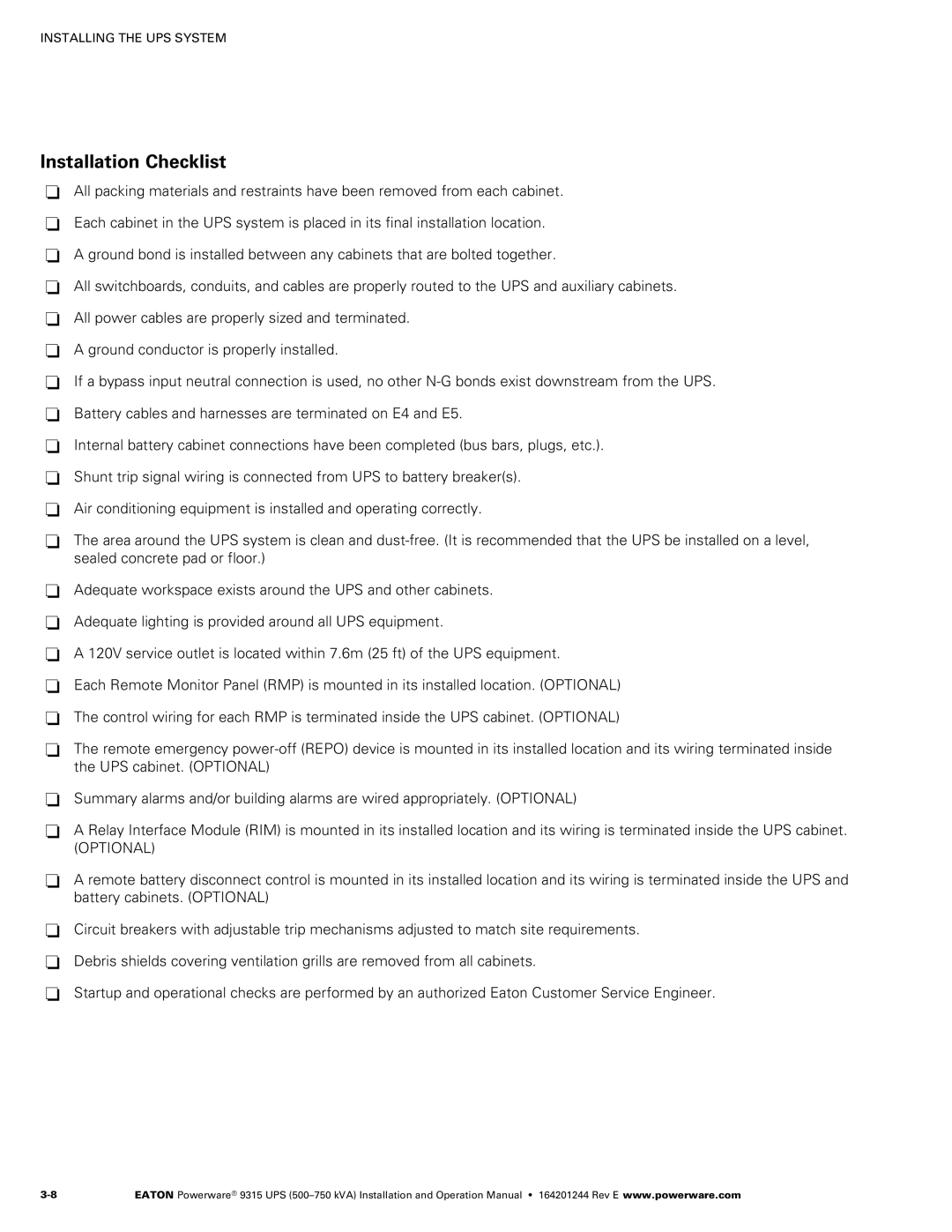

Installation Checklist

-All packing materials and restraints have been removed from each cabinet.

-Each cabinet in the UPS system is placed in its final installation location.

-A ground bond is installed between any cabinets that are bolted together.

-All switchboards, conduits, and cables are properly routed to the UPS and auxiliary cabinets.

-All power cables are properly sized and terminated.

-A ground conductor is properly installed.

-If a bypass input neutral connection is used, no other N‐G bonds exist downstream from the UPS.

-Battery cables and harnesses are terminated on E4 and E5.

-Internal battery cabinet connections have been completed (bus bars, plugs, etc.).

-Shunt trip signal wiring is connected from UPS to battery breaker(s).

-Air conditioning equipment is installed and operating correctly.

-The area around the UPS system is clean and dust‐free. (It is recommended that the UPS be installed on a level, sealed concrete pad or floor.)

-Adequate workspace exists around the UPS and other cabinets.

-Adequate lighting is provided around all UPS equipment.

-A 120V service outlet is located within 7.6m (25 ft) of the UPS equipment.

-Each Remote Monitor Panel (RMP) is mounted in its installed location. (OPTIONAL)

-The control wiring for each RMP is terminated inside the UPS cabinet. (OPTIONAL)

-The remote emergency

-Summary alarms and/or building alarms are wired appropriately. (OPTIONAL)

-A Relay Interface Module (RIM) is mounted in its installed location and its wiring is terminated inside the UPS cabinet. (OPTIONAL)

-A remote battery disconnect control is mounted in its installed location and its wiring is terminated inside the UPS and battery cabinets. (OPTIONAL)

-Circuit breakers with adjustable trip mechanisms adjusted to match site requirements.

-Debris shields covering ventilation grills are removed from all cabinets.

-Startup and operational checks are performed by an authorized Eaton Customer Service Engineer.

EATON Powerware® 9315 UPS |