FORM

SECTION 2 – INSTALLATION

APPROVALS

Designed certified by CSA, ETL, CETL as follows:

1.For use as a forced air furnace with cooling unit (gas heat models).

2.For outdoor installation only.

3.For installation on combustible material and may be installed directly on combustible flooring or Class A, Class B or Class C roof covering mate- rials.

4.For use with natural gas or LP.

5.When used with LP propane gas one of the follow- ing conversion kits must be installed before the gas heat section is fired:

375,000 BTU Input -

750,000 BTU Input -

1,125,000 BTU Input -

Not suitable for use with conventional venting systems.

LIMITATIONS

The installation of this unit must conform to local building codes, or in the absence of local codes, with ANSI 223.1 Natural Fuel Gas Code and /or CAN/CGA B149 installation codes.

In U.S.A.:

1.National Electrical CodeANSI/NFPANo. 70 - Lat- est Edition.

2.National Fuel Gas Code Z223.1 - Latest Edition.

3.

4.Local gas utility requirements.

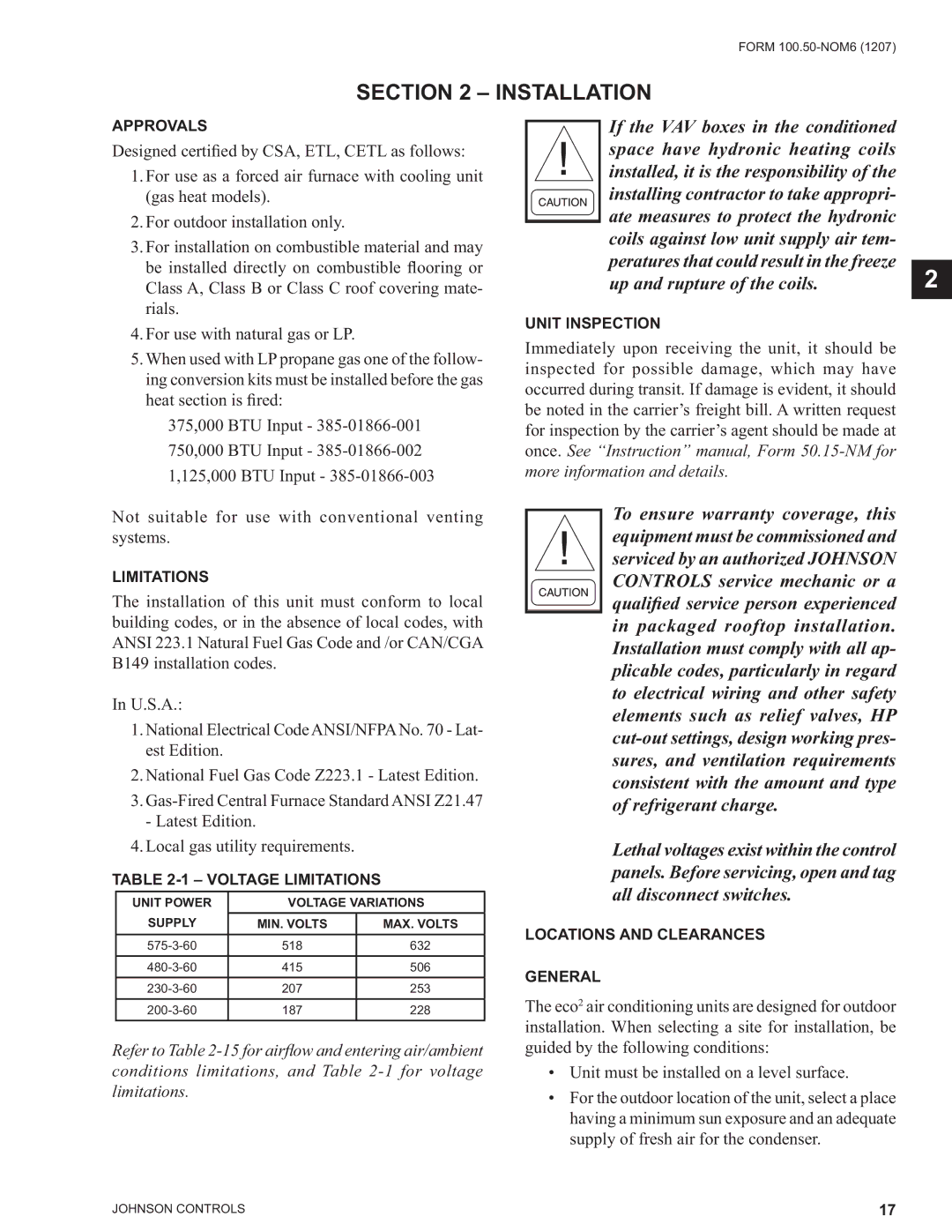

TABLE 2-1 – VOLTAGE LIMITATIONS

UNIT POWER | VOLTAGE VARIATIONS | |

SUPPLY | MIN. VOLTS | MAX. VOLTS |

518 | 632 | |

415 | 506 | |

207 | 253 | |

|

|

|

187 | 228 | |

Refer to Table

If the VAV boxes in the conditioned |

|

space have hydronic heating coils |

|

installed, it is the responsibility of the |

|

installing contractor to take appropri- |

|

ate measures to protect the hydronic |

|

coils against low unit supply air tem- |

|

peratures that could result in the freeze | 2 |

up and rupture of the coils. |

UNIT INSPECTION

Immediately upon receiving the unit, it should be inspected for possible damage, which may have occurred during transit. If damage is evident, it should be noted in the carrier’s freight bill. A written request for inspection by the carrier’s agent should be made at once. See “Instruction” manual, Form

To ensure warranty coverage, this equipment must be commissioned and serviced by an authorized JOHNSON CONTROLS service mechanic or a qualified service person experienced in packaged rooftop installation. Installation must comply with all ap- plicable codes, particularly in regard to electrical wiring and other safety elements such as relief valves, HP

Lethal voltages exist within the control panels. Before servicing, open and tag all disconnect switches.

LOCATIONS AND CLEARANCES

GENERAL

The eco2 air conditioning units are designed for outdoor installation. When selecting a site for installation, be guided by the following conditions:

•Unit must be installed on a level surface.

•For the outdoor location of the unit, select a place having a minimum sun exposure and an adequate supply of fresh air for the condenser.

JOHNSON CONTROLS | 17 |