Maintenance

Condenser Coils

Dirt should not be allowed to accumulate on the condenser coil surfaces. Cleaning should be as often as necessary to keep coil clean.

PERIODIC MAINTENANCE – THREE TO SIX MONTHS

Disconnect and

Squealing belts during starting is caused by slipping belts that are not tensioned properly.

Motor Bearing Lubrication

Bearings must be

Belt Tension

Adjust the belt tension if necessary. Required belt tension data is supplied on the fan “skid” data plate, attached to the fan housing. Never use a belt dressing on the belts. If belts slip with the proper tension, use a good grade of belt cleanser to clean the belts. Refer to Figures

Never use excessive belt tension, as this could result in damaging the bearing, motor pulleys or motor base. See drive label on fan housing adjacent to drive for specific details on tension.

When it is necessary to replace one belt in a given set, the entire set of belts must be replaced.

FORM

PERIODIC MAINTENANCE – YEARLY

Check the fan wheels and inspect the drain pan for sludge and foreign material. Clean if required.

Observe the operation of all dampers and make any necessary adjustments in linkage and blade orientation for proper operation.

Entire Unit Inspection

In addition to the checks listed in this section, periodic overall inspections of the unit should be accomplished to ensure proper equipment operation. Items such as loose hardware, component operation, refrigerant leaks, unusual noises, etc. should be investigated and corrected immediately.

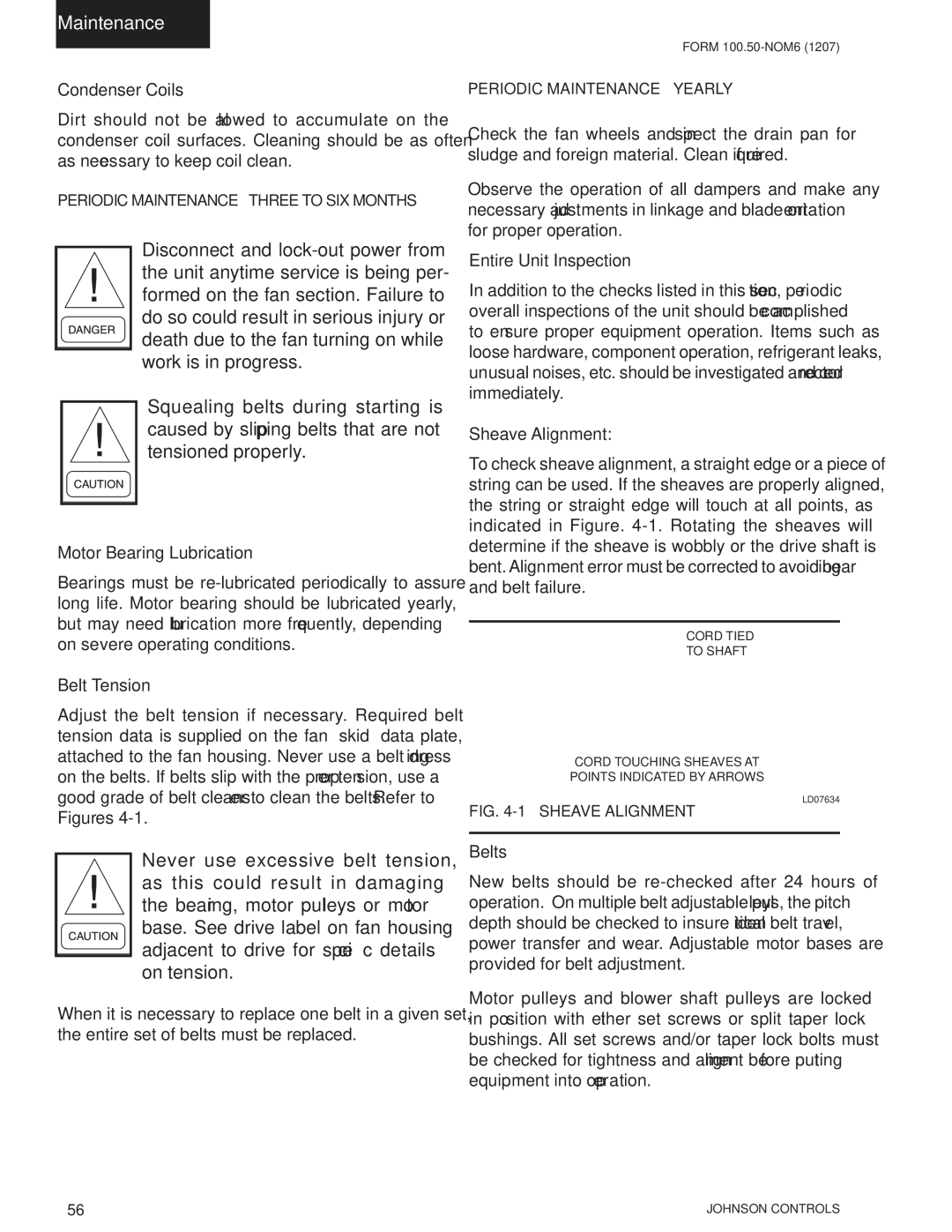

Sheave Alignment:

To check sheave alignment, a straight edge or a piece of string can be used. If the sheaves are properly aligned, the string or straight edge will touch at all points, as indicated in Figure.

CORD TIED

TO SHAFT

CORD TOUCHING SHEAVES AT

POINTS INDICATED BY ARROWS

LD07634

FIG. 4-1 – SHEAVE ALIGNMENT

Belts

New belts should be

Motor pulleys and blower shaft pulleys are locked in position with either set screws or split taper lock bushings. All set screws and/or taper lock bolts must be checked for tightness and alignment before putting equipment into operation.

56 | JOHNSON CONTROLS |