Maintenance

Prior to installing the bearing on the shaft, it should be worked around in the housing to make sure that

FORM

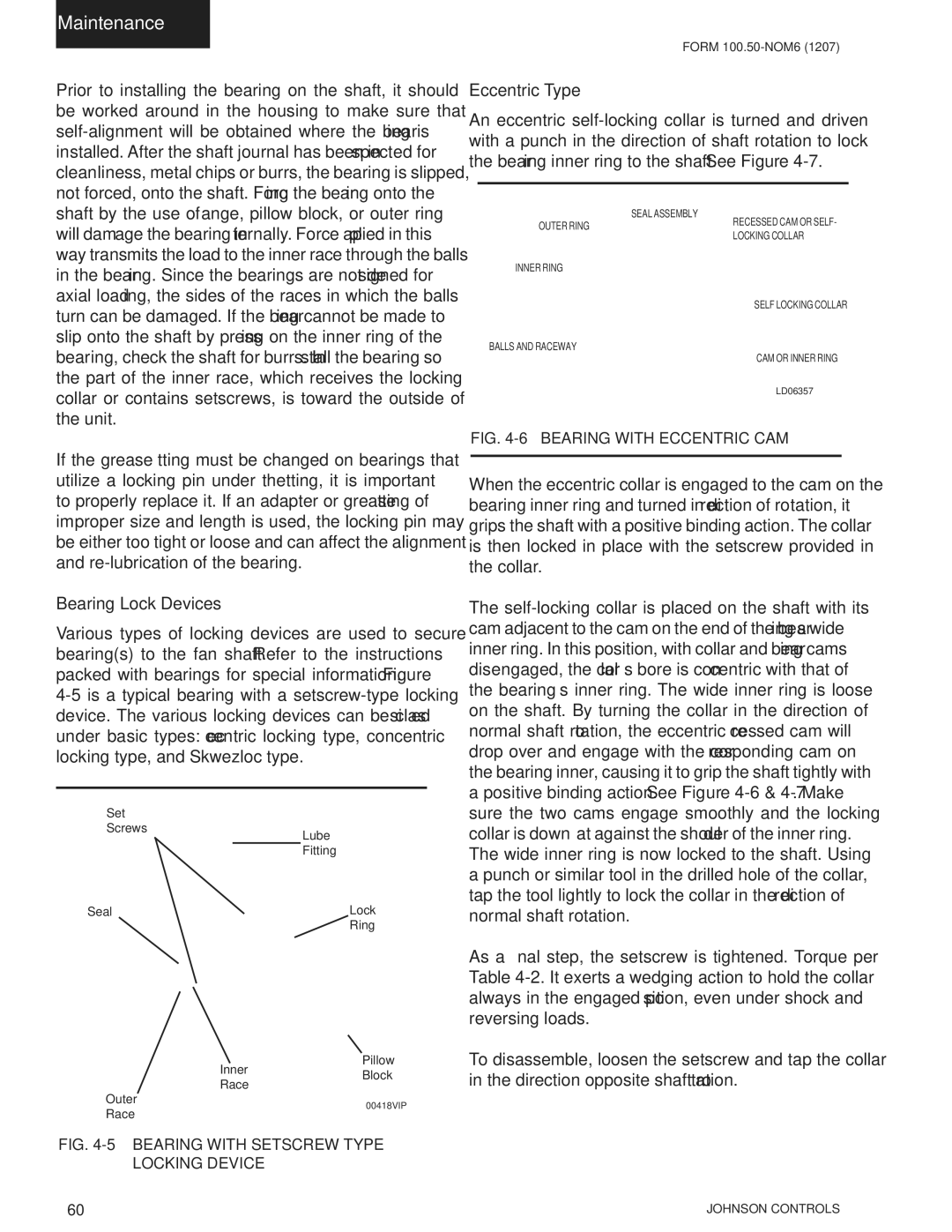

Eccentric Type

An eccentric

shaft by the use of flange, pillow block, or outer ring will damage the bearing internally. Force applied in this way transmits the load to the inner race through the balls in the bearing. Since the bearings are not designed for axial loading, the sides of the races in which the balls turn can be damaged. If the bearing cannot be made to slip onto the shaft by pressing on the inner ring of the bearing, check the shaft for burrs. Install the bearing so the part of the inner race, which receives the locking collar or contains setscrews, is toward the outside of the unit.

OUTER RING

INNER RING

BALLS AND RACEWAY

SEAL ASSEMBLY

RECESSED CAM OR SELF- LOCKING COLLAR

SELF LOCKING COLLAR

CAM OR INNER RING

LD06357

If the grease fitting must be changed on bearings that utilize a locking pin under the fitting, it is important to properly replace it. If an adapter or grease fitting of improper size and length is used, the locking pin may be either too tight or loose and can affect the alignment and

Bearing Lock Devices

Various types of locking devices are used to secure bearing(s) to the fan shaft. Refer to the instructions packed with bearings for special information. Figure

FIG. 4-6 – BEARING WITH ECCENTRIC CAM

When the eccentric collar is engaged to the cam on the bearing inner ring and turned in direction of rotation, it grips the shaft with a positive binding action. The collar is then locked in place with the setscrew provided in the collar.

The

Set

Screws

Seal

Inner

Race

Outer

Race

Lube |

Fitting |

Lock |

Ring |

Pillow |

Block |

00418VIP

sure the two cams engage smoothly and the locking collar is down flat against the shoulder of the inner ring. The wide inner ring is now locked to the shaft. Using a punch or similar tool in the drilled hole of the collar, tap the tool lightly to lock the collar in the direction of normal shaft rotation.

As a final step, the setscrew is tightened. Torque per Table

To disassemble, loosen the setscrew and tap the collar in the direction opposite shaft rotation.

FIG. 4-5 – BEARING WITH SETSCREW TYPE LOCKING DEVICE

60 | JOHNSON CONTROLS |