Tuning Procedures

Consider the following before determining the inertia:

•If your application allows a great deal of motor motion without interference, it is recommended that you use a Preset Velocity to produce accurate acceleration ramps.

•If your application has a very limited range of motion, it is recommended that you use a position controller to produce the acceleration ramps and to prevent exceeding the axis range of motion.

•The accel and decel ramp should be aggressive enough to require at least 20 percent of continuous motor torque. The higher the torque used during the ramp, the more accurate the final result will be.

•With ramps that take less than 1/2 second to accelerate, read the Diagnostic Analog Outputs with an oscilloscope to measure the Torque Feedback.

•With ramps that take 1/2 second or longer to accelerate, read the Torque Command parameter on the Motor tab of PowerTools or with the Watch Window.

•To best determine the inertia, use both acceleration and deceleration torque values. The difference allows you to drop the constant friction out of the final calculation.

•If your application exerts a constant “unidirectional loading” throughout the travel such as in a vertical axis, the inertia test profiles must be performed in both directions to cancel out the unidirectional loading effect.

•The Torque Command Limited and Velocity Feedback parameters can be measured using the drive’s Analog Outputs, PowerTools software or an

An oscilloscope will be needed for systems with limited travel moves and rapidly changing signals of torque and velocity.

Inertia Measurement Procedure:

Note

The test profile will need to be run a number of times in order to get a good sample of data.

1.Enable the drives and run the test profiles.

2.Note the Torque Command Limited value during acceleration and deceleration.

3.Use the appropriate formula below to calculate the inertia.

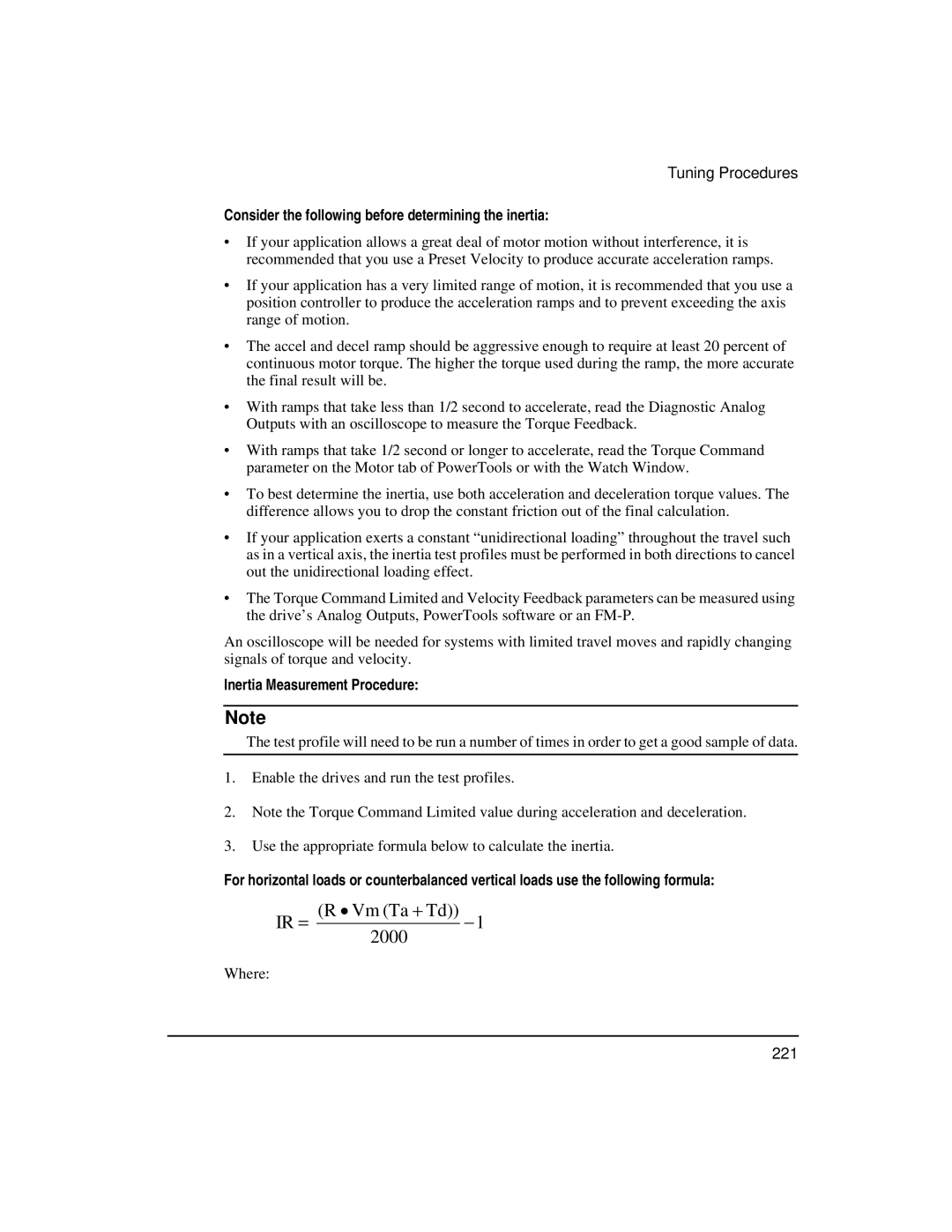

For horizontal loads or counterbalanced vertical loads use the following formula:

IR = (R • Vm (Ta + Td)) −1 2000

Where:

221