Tuning Procedures

Initial Test Settings

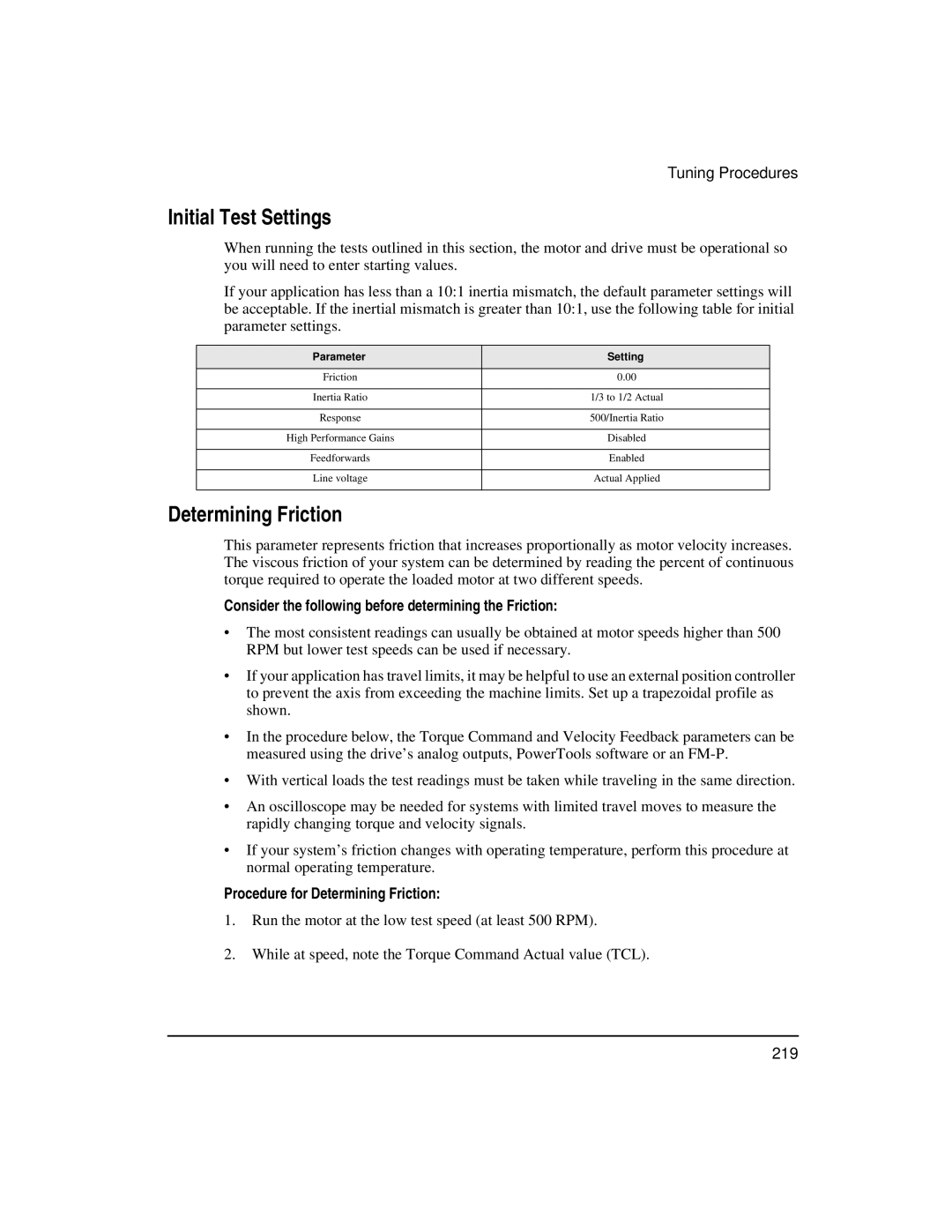

When running the tests outlined in this section, the motor and drive must be operational so you will need to enter starting values.

If your application has less than a 10:1 inertia mismatch, the default parameter settings will be acceptable. If the inertial mismatch is greater than 10:1, use the following table for initial parameter settings.

Parameter | Setting |

|

|

Friction | 0.00 |

|

|

Inertia Ratio | 1/3 to 1/2 Actual |

|

|

Response | 500/Inertia Ratio |

|

|

High Performance Gains | Disabled |

|

|

Feedforwards | Enabled |

|

|

Line voltage | Actual Applied |

|

|

Determining Friction

This parameter represents friction that increases proportionally as motor velocity increases. The viscous friction of your system can be determined by reading the percent of continuous torque required to operate the loaded motor at two different speeds.

Consider the following before determining the Friction:

•The most consistent readings can usually be obtained at motor speeds higher than 500 RPM but lower test speeds can be used if necessary.

•If your application has travel limits, it may be helpful to use an external position controller to prevent the axis from exceeding the machine limits. Set up a trapezoidal profile as shown.

•In the procedure below, the Torque Command and Velocity Feedback parameters can be measured using the drive’s analog outputs, PowerTools software or an

•With vertical loads the test readings must be taken while traveling in the same direction.

•An oscilloscope may be needed for systems with limited travel moves to measure the rapidly changing torque and velocity signals.

•If your system’s friction changes with operating temperature, perform this procedure at normal operating temperature.

Procedure for Determining Friction:

1.Run the motor at the low test speed (at least 500 RPM).

2.While at speed, note the Torque Command Actual value (TCL).

219