TM-L90/TM-L90 with Peeler Technical Reference Guide

B.2.2.3 Print Density Adjustment

For best print quality and reliability, select the proper print density for the paper type used as described in the table below. If printing is performed with a density that exceeds the density described in the table below, the reliability

Original paper no. | Density level |

|

|

HW76B, KL470, KL80GT | 130% |

|

|

B.2.2.4 Paper to Use for High Speed

If any of the following original paper types of thermal paper are used, the memory switch for the customized value setting can be used to set the maximum print speed up to 150 mm/s {5.91"/s} (level 9); however when the peeling issuing mode is selected, set the maximum print speed to 120 mm/s or less.

B.2.2.5 If paper other than the specified original paper is used

If paper other than the specified original paper is used, confirm whether the paper meets the requirements for the thickness, the peeling strength, and the transparency rates.

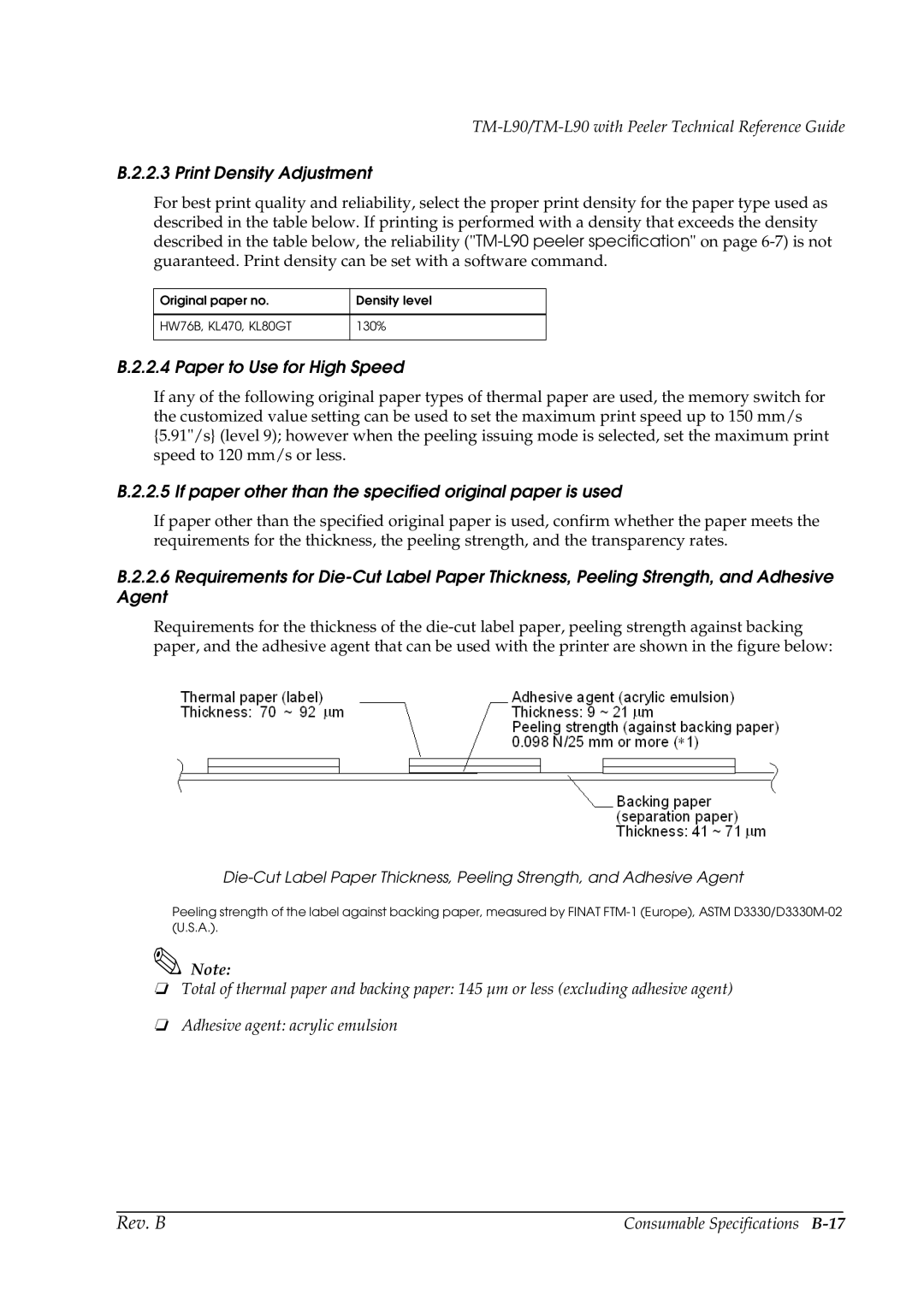

B.2.2.6 Requirements for

Requirements for the thickness of the

Peeling strength of the label against backing paper, measured by FINAT

Note:

❏Total of thermal paper and backing paper: 145 µm or less (excluding adhesive agent)

❏Adhesive agent: acrylic emulsion

Rev. B | Consumable Specifications |