STUDIO160/200/250

Toshiba TEC Corporation

All rights reserved

Installation

Service of Machines

Transportation

Main Service Parts for Safety

Disposition of Consumable Parts/Packing Materials

Contents

Maintenance Performed Every 81,000 e-STUDIO160/200 Series

Troubleshooting Based on Error Code

Other service call Troubleshooting of Image

Wire Harness Connection Diagrams

Page

Adjustment Items

Error Code List

EA2

Radf

EA1

EA3

December 2002 Toshiba TEC STUDIO160/200/250 Adjustment Items

Radf

CB1

CA1

CA2

CB2

Self-Diagnosis Modes

Maintenance

After entering Service Mode

Function

INT

Turn on the power switch

Power OFF Turn on the power switch

Press the Interrupt key

SET Start

Adjustment value Enter code

Cancel Adjustment value

Display messages

Adjust Mode 05 Items

Process unit adjustment

Scanning adjustment

Printer adjustment

Scan image processing parameter 600 DPI

Use of default value Larger the intensity Text/Photo mode

System Mode 08 Items

Setting value Enter code

Cancel

Setting value

Maint

Mode 375

Print

NON Sort 1 Staple 2 Sort

Completed

Auto Test

SET

Individual Test

Program

SET CIS

Select Test Mode

Test Result List

Select Test Result List Use or keys

Following tests can be conducted in the Function test mode

OPE. Panel Test Print Test

Modem Test *1 Factory test

OPE Panel Test

Cursor moves from the upper left to the lower right

Digital Keys Select paper cassette C

Digital Keys Print setup 1 T

Digital Keys Print setup 2 B

Print code

Test Print 02 Items

BIT

Display selection Cancel Display messages

Sensor Test

12 S1

Display is switched using the or key Status display example

PFC

IO4 Bit2

PWA

IO1 IO1

With bits 4 and 5 of IO1 Bit7 Bit6

Sensor Test 04 Items

MEM1DET

Bucs

16MBDET

Sizpfu

EXIT-SW

Cancel Display messages

Function Test 06.DRAM Test 07.CLOCK IC Test 08.SCANNER Test

Digital Keys Enter test mode Test code

Select test menu

Test start Test stop

Output Test 10 Items

Page

Printer Board Test

End of test Cancel Display messages

Maintenance Memory Clear

Warming up Ready Standby

Select Memory Clear Use or keys

Select Maintenance Use or keys

Item selection from menu Key used in operation

Select menu

RAM clear table

Func

December 2002 Toshiba TEC STUDIO160/200/250 Adjustment Items

SET Function

Cancel SET

Error Counter Shift

Memory Write

Service List

Protocol Trace *1 Total Errors *1

Drum History

COUNTRY/REGION

Total Errors

Protocol Trace

Country/Region code

Drum Counter

Current Counter

Total Print

History

Memory dump start address. The last digit is always 0. *1

Memory Dump List

Address

HEX Ascii

Select Lists

Select Function Use or keys

Print list

Paper JAM

JAM Counter

Document

TYPE1 JAM

NAD

ASD/AUD/CND/SAD/MJD

Test Mode PA

Adjust the volume Use Keys

Select Default Setting Use Keys

Select Machine Default Use Keys

Use Keys

SET Cancel

Adjust the document guide to the widest Enter code

Image Quality Control

SET INT Start

Code Set the value Test print

Copy Image Dimension Adjustment

Power on Code

Digital Keys SET INT Start INT Set the value or Test copy

Interrupt Program 05TEST Mode SET

04FUNCTION Test SET 02PRINT Test

Main Menu Interrupt SET

Main Menu Interrupt

5C15

Registration Adjustment order

Adjust the installed option units

LCF

443

Copy movement direction 100

Copied scale Copy movement direction Actual scale

01-04-10

Code Set the value Test copy

Power on Code Set the value

Sharpness HPF Adjustment

Code Default value 620 621 622

Enter code Set the value

Gamma Slope Correction

High-Voltage Adjustment

000

Door switch jigs Door switch jig Large Door switch jig Small

Start Cancel

Current entried adjustment value

SET Value YYY after adjustment is stored to SRAM. or

Return to other adjustment mode Power OFF

December 2002 Toshiba TEC STUDIO160/200/250 Adjustment

Copy trailing edge

Copy leading edge Copy trailing edge

Adjusting the Scanner Section

Tab Stopper Original glass

Scanner motor

Roller Holding part Lamp cable Carriage

057-3-1

Wire Scanner drive shaft

Rear Side Front Side

Relationship between wound turns and wire holder jigs

CCD unit Replacing the CCD unit

CCD Jig CCD unit

065-04-2

065-04-3

Adjusting the main drive gear assembly

Release the jam lever of the fuser

Main motor Gear Fuser Jam lever

Plate Screw a Main drive gear assembly Collar

Main PWA replacement procedure

Initial Setup Date & Time

CND SET

December 2002 Toshiba TEC STUDIO160/200/250 Adjustment Items

Display messages and measurement methods

Output Test SET Start Cancel

Measurement of Transfer Guide Bias

Enter the Transfer Guide Bias ON/OFF code

From preceding

CLEAR/STOP Cancel

Power OFF To measure on the paper guide plate

Turn the transfer guide bias OFF End the output test

Adjustment of the doctor-sleeve gap

Preventive Maintenance Check List

Symbols used in the check list

Page

Main Rear view

Fuser unit Pressure roller

Check

Doctor blade cleaning jig Magnetic roller

Drive gear

HR drive gear Boss

Page

MY-1015

MD-0101

MJ-5002

MY-1016

MR-3011

MJ-5001

KD-1009

MR-2012

KD-1010

PM Kit

List of Adjustment Tools

List of Grease

Precautions for Storing & Handling Supplies

Precautions for Storing Toshiba Supplies

Checking and Cleaning of the Pressure Roller

Checking and Cleaning of the Cleaning Roller

Checking and Cleaning of the Heat Roller

Checking and Replacing of the Transfer Guide Roller

Checking and Cleaning of the Photoconductive Drum

Checking and Cleaning of the Drum Cleaning Blade

Troubleshooting

Troubleshooting Based on Error Code

YES

YES

YES

YES

YES

YES

YES

YES

Open- or short-circuited

PWA CN205 is disconnected

PWA CN36 is disconnected

Replace the 2nd feed roller clutch

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

Set only one-size originals Is the separation pad stained?

Replace the rollers

YES

YES

Clean the rollers Is the reverse flapper working properly?

EA2

Remove the paper Is the finisher connected to the main unit?

EA5

EA7

STUDIO160/200/250 Troubleshooting December 2002 Toshiba TEC

YES

YES

YES

YES 1

YES

YES

YES

YES

YES

STUDIO160/200/250 Troubleshooting December 2002 Toshiba TEC

Replace the main PWA

STUDIO160/200/250 Troubleshooting December 2002 Toshiba TEC

December 2002 Toshiba TEC STUDIO160/200/250 Troubleshooting

YES

YES

Radf

December 2002 Toshiba TEC STUDIO160/200/250 Troubleshooting

STUDIO160/200/250 Troubleshooting December 2002 Toshiba TEC

YES

YES END

CC8

CC9

CCA

CCB

YES

STUDIO160/200/250 Troubleshooting December 2002 Toshiba TEC

December 2002 Toshiba TEC STUDIO160/200/250 Troubleshooting

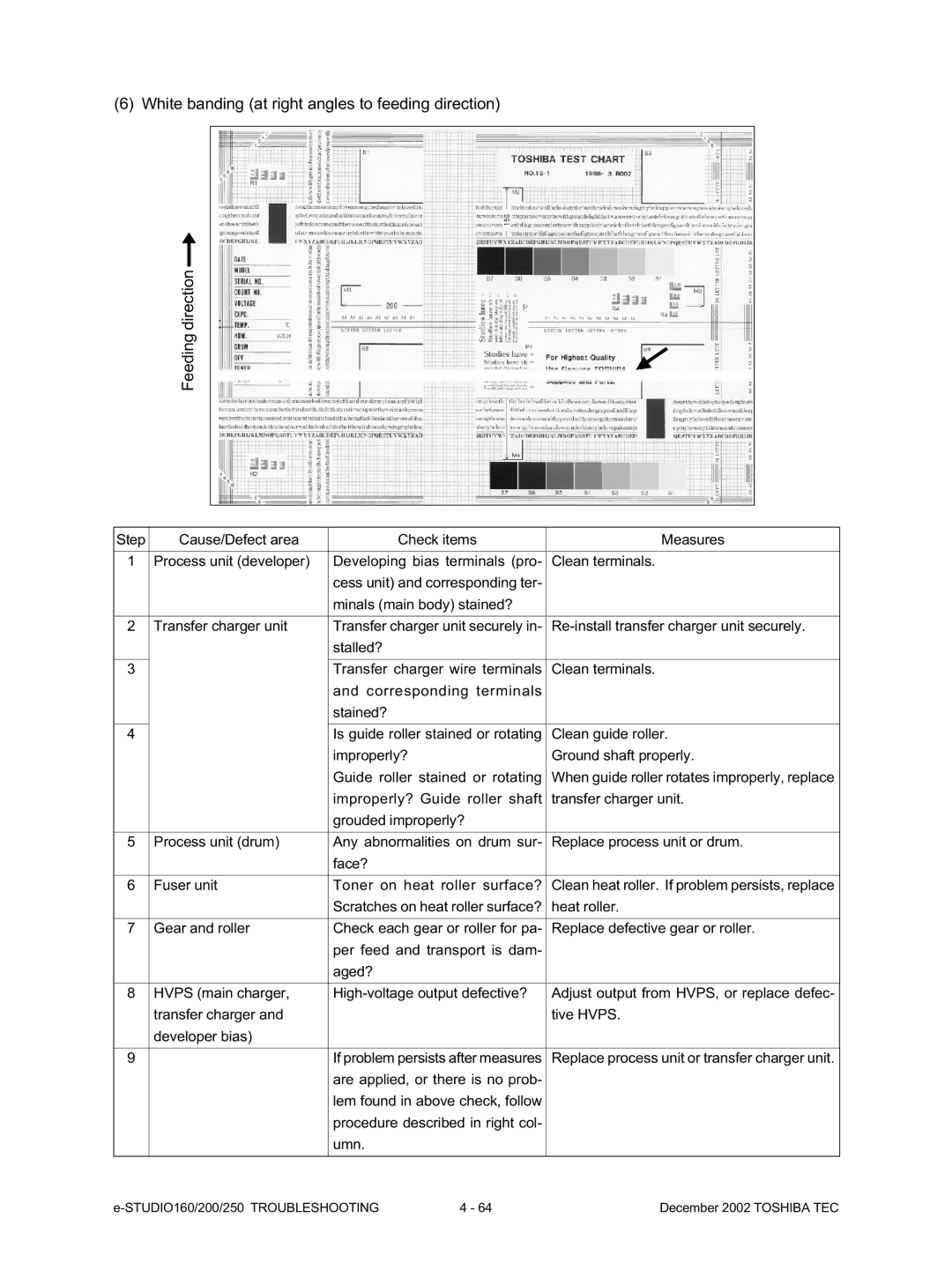

Troubleshooting of Image

Uneven pitch and blur Symptoms

Feeding direction

Replace registration roller

Blurred image Feeding direction

Re-install transfer charger unit securely

Solid copy Feeding direction

White banding in feeding direction Feeding direction

Minals main body stained? Transfer charger unit

Black banding in feeding direction Feeding direction

Main charger Formed? Or charger wire

White Spots Feeding direction

Uneven image density Feeding direction

Blotched image Feeding direction

Poor image transfer Feeding direction

Poor cleaning Feeding direction

Hvps

Background Fogging Feeding direction

Toner offset

Poor fusing Feeding direction

Defect of image density/Gray balance

Moire/lack of sharpness Feeding direction

Lack of sharpness

Uneven light distribution Feeding direction

Skew inclined image Feeding direction Moire

Image dislocation in feeding direction Feeding direction

Jittering image Feeding direction

Updating the Firmware

Outline

Using the Recovery PWA

Turn off the power Remove the rear cover

Main PWA Main recovery PWA CN10

Page

Connector Scanner recovery PWA

Remove the blind plate

Page

Using the Batch File

MKRPCDSK.BAT DISK.EXE

MS-DOS prompt screen shows the following

Type mkrpcdsk and press the Enter key

Press the Enter key. Formatting of Disk 1 begins

When formatting is completed, the following screen appears

Press the Enter key Type n and press the Enter key

Download program is copied to Disk

Press the Enter key Formatting of Disk 2 begins

05-03-014

05-03-016

When copying is completed, the following screen appears

05-03-019

LCD display on the copier

05-03-022

05-03-023

When downloading ends, the following screen appears

Using the Toshiba Viewer

Page

Page

Page

Wire Harness

Wire Harness Connection Diagrams

Connector Table

Appendix A. Specifications

PFU PFP LCF

LT-R

LD ST-R, COM

STUDIO200 series Less than 7.0 seconds A4/LT, the Upper cas

STUDIO160 series Less than 7.9 seconds A4/LT, the Upper cas

Sette, 100%, original placed manually

STUDIO250 series Less than 7.0 seconds A4/LT, the Upper cas

Weight

Appendix B. Accessories

Appendix D. Replacement Units/Supplies

Appendix C. Options

Appendix E. System List

Fig. E-1

Appendix F. Power Supply Unit

24VSW

+24 24VFU2 24VFU1 12V +12

5VPS

Kanda NISHIKI-CHO, CHIYODA-KU, TOKYO, 101-8842 Japan