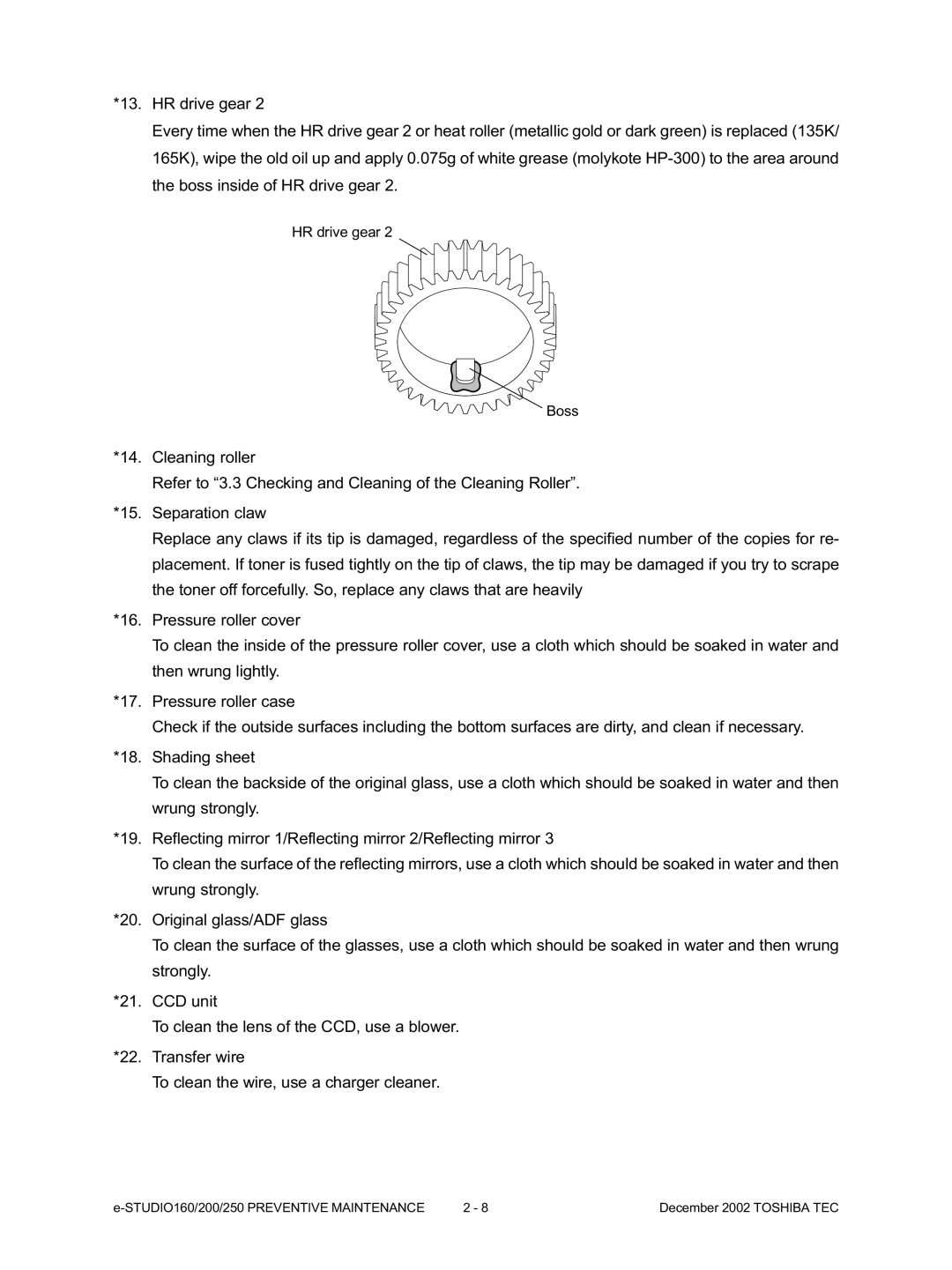

*13. HR drive gear 2

Every time when the HR drive gear 2 or heat roller (metallic gold or dark green) is replaced (135K/ 165K), wipe the old oil up and apply 0.075g of white grease (molykote

HR drive gear 2

Boss

*14. Cleaning roller

Refer to “3.3 Checking and Cleaning of the Cleaning Roller”.

*15. Separation claw

Replace any claws if its tip is damaged, regardless of the specified number of the copies for re- placement. If toner is fused tightly on the tip of claws, the tip may be damaged if you try to scrape the toner off forcefully. So, replace any claws that are heavily

*16. Pressure roller cover

To clean the inside of the pressure roller cover, use a cloth which should be soaked in water and then wrung lightly.

*17. Pressure roller case

Check if the outside surfaces including the bottom surfaces are dirty, and clean if necessary.

*18. Shading sheet

To clean the backside of the original glass, use a cloth which should be soaked in water and then wrung strongly.

*19. Reflecting mirror 1/Reflecting mirror 2/Reflecting mirror 3

To clean the surface of the reflecting mirrors, use a cloth which should be soaked in water and then wrung strongly.

*20. Original glass/ADF glass

To clean the surface of the glasses, use a cloth which should be soaked in water and then wrung strongly.

*21. CCD unit

To clean the lens of the CCD, use a blower.

*22. Transfer wire

To clean the wire, use a charger cleaner.

2 - 8 | December 2002 TOSHIBA TEC |