2. PREVENTIVE MAINTENANCE (PM)

2.1Maintenance Performed Every 81,000

(1)Preparation

![]() Ask user about the current machine condition and note them down.

Ask user about the current machine condition and note them down.

![]() Before starting maintenance, make some sample copies and save them.

Before starting maintenance, make some sample copies and save them.

![]() Turn OFF the power, and be sure to unplug the copier.

Turn OFF the power, and be sure to unplug the copier.

(2)Perform preventive maintenance using the following checklist and the illustrations. Refer to the Ser- vice Manual and Parts List if necessary.

(3)When the maintenance is finished, plug in the copier, turn ON the power, and make a few copies to confirm that the copier is working properly.

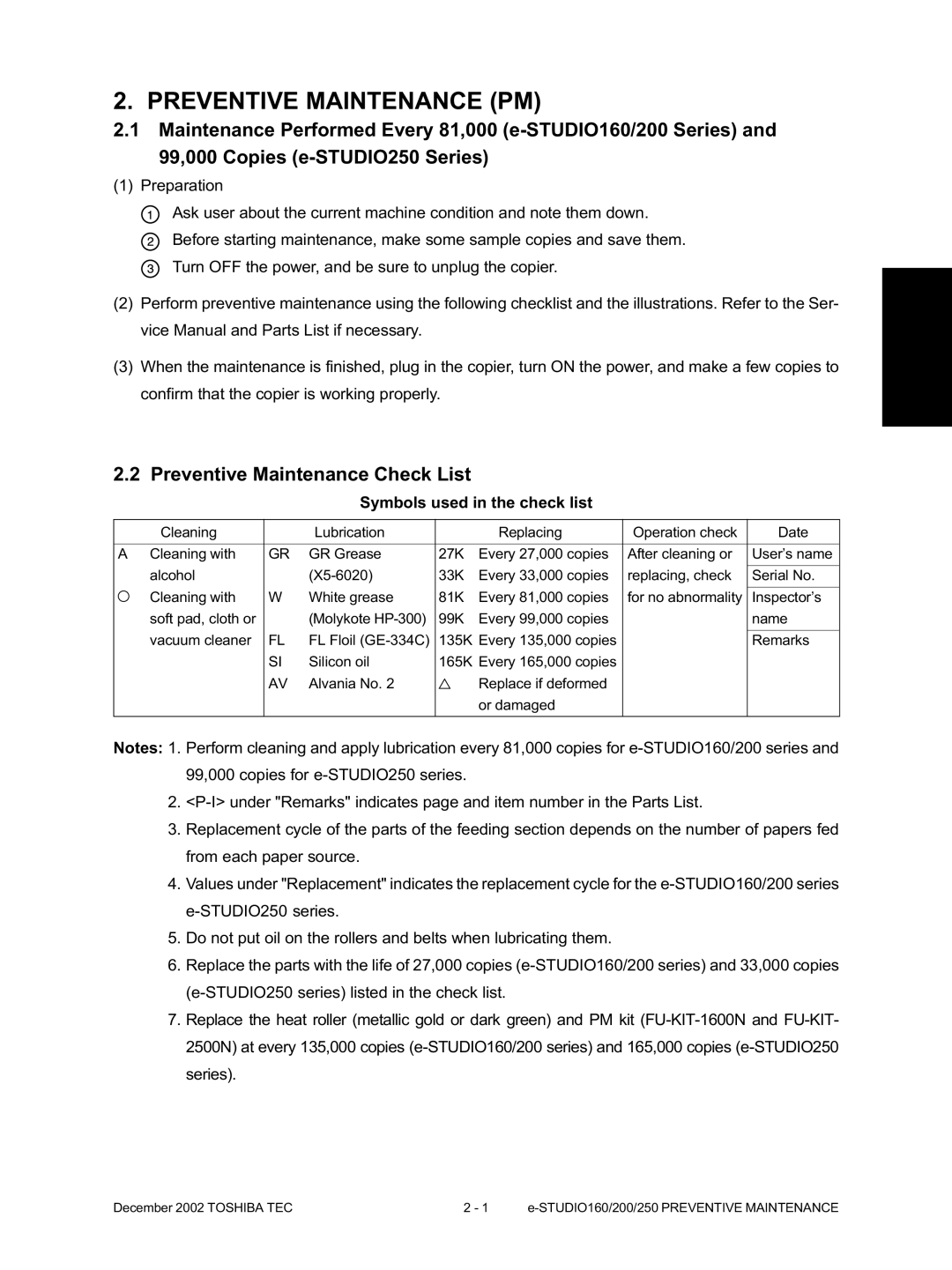

2.2 Preventive Maintenance Check List

Symbols used in the check list

Cleaning |

| Lubrication |

| Replacing | Operation check | Date |

|

|

|

|

|

|

|

A Cleaning with | GR | GR Grease | 27K | Every 27,000 copies | After cleaning or | User’s name |

|

|

|

|

|

|

|

alcohol |

| 33K | Every 33,000 copies | replacing, check | Serial No. | |

Cleaning with |

|

|

|

|

|

|

W | White grease | 81K | Every 81,000 copies | for no abnormality | Inspector’s | |

soft pad, cloth or |

| (Molykote | 99K | Every 99,000 copies |

| name |

vacuum cleaner |

|

|

|

|

| |

FL | FL Floil | 135K Every 135,000 copies |

| Remarks | ||

| SI | Silicon oil | 165K Every 165,000 copies |

|

| |

| AV | Alvania No. 2 |

| Replace if deformed |

|

|

|

|

|

| or damaged |

|

|

|

|

|

|

|

|

|

Notes: 1. Perform cleaning and apply lubrication every 81,000 copies for

2.

3.Replacement cycle of the parts of the feeding section depends on the number of papers fed from each paper source.

4.Values under "Replacement" indicates the replacement cycle for the

5.Do not put oil on the rollers and belts when lubricating them.

6.Replace the parts with the life of 27,000 copies

7.Replace the heat roller (metallic gold or dark green) and PM kit

December 2002 TOSHIBA TEC | 2 - 1 |