*Notes on the Preventive Maintenance Checklist

*1. Photoconductive drum

Refer to "3.6 Checking and Cleaning of Photoconductive Drum".

*2. Drum cleaning blade

Since the edge of the blade is breakable and can be easily damaged by matters such as the adherence of paper dust. Replace the cleaning blade with a new one if poor images are copied due to the damaged blade regardless of the number of copies which have been made.

*3. Main charger case/main charger wire

Clean the main charger case and wire with a cloth soaked in water and then squeezed tightly. Note: Be careful of the following when attaching a new wire (length: 358mm).

·Do not twist the wire.

·Do not touch the wire with your bare hand.

*4. Separation claws for the drum

The paper jam may be caused if the tip of the separation claw is damaged or deformed. If there is any problem with it, replace the claw with a new one regardless of the number of copies which have been made.

If any mark which was made by the claw appears on the copied image, clean the tip of the claw. Notes:1. Wipe the tip of the claw lightly with a dry cloth trying not to deform it.

Do not leave the lint on the tip.

2.Apply patting power to the tip of the claws and drum surface after replacing or cleaning them to reduce the load on the drum surface by the claw.

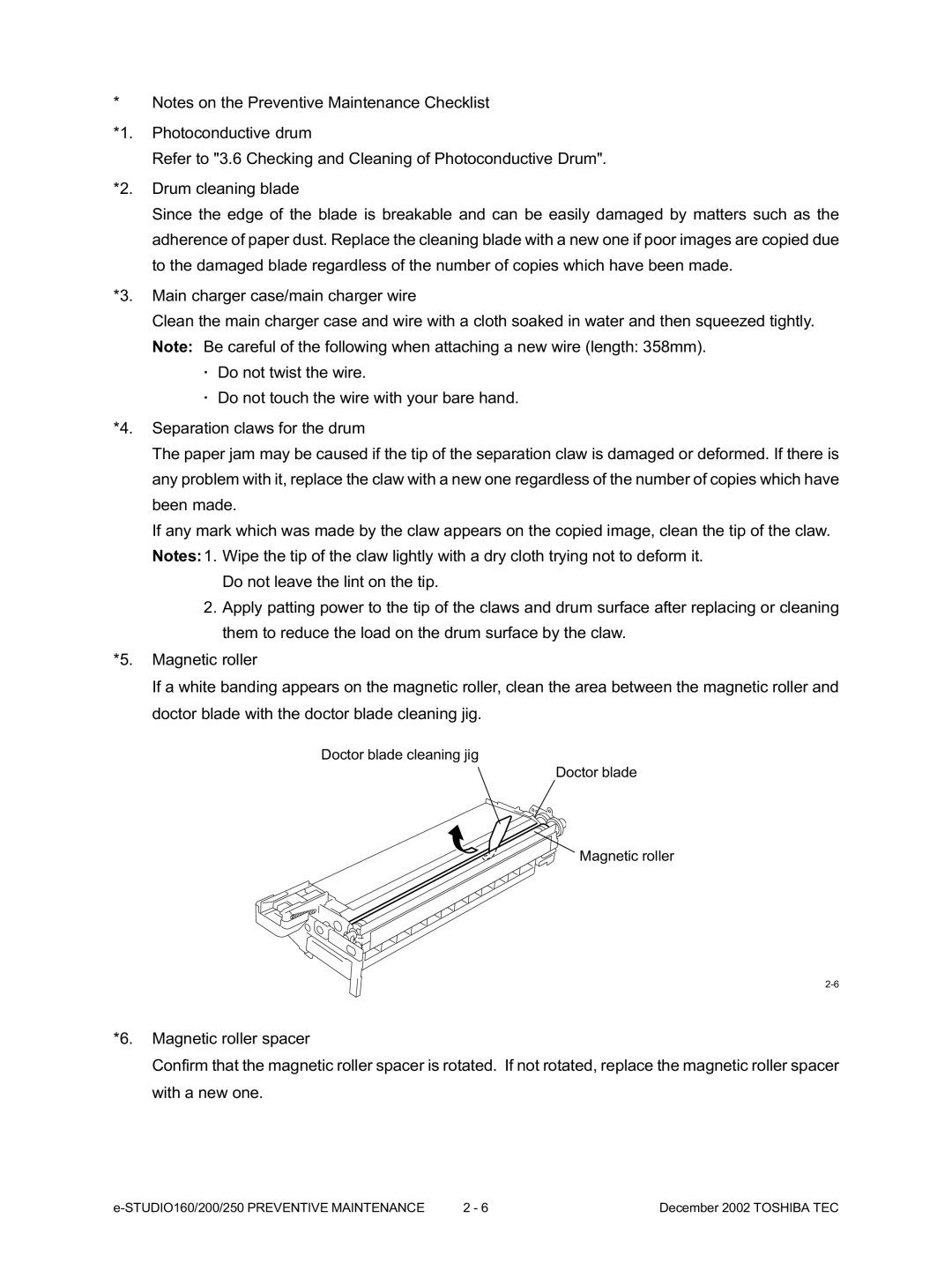

*5. Magnetic roller

If a white banding appears on the magnetic roller, clean the area between the magnetic roller and doctor blade with the doctor blade cleaning jig.

Doctor blade cleaning jig

Doctor blade

Magnetic roller

*6. Magnetic roller spacer

Confirm that the magnetic roller spacer is rotated. If not rotated, replace the magnetic roller spacer with a new one.

2 - 6 | December 2002 TOSHIBA TEC |