MMD-AP0181H, AP0241H, AP0271H MMD-AP0361H, AP0481H

MMD-AP0071SPH, AP0091SPH, AP0121SPH

MMC-AP0151H, AP0181H, AP0241H MMC-AP0271H, AP0361H, AP0481H

MML-AP0071H, AP0091H, AP0121H MML-AP0151H, AP0181H, AP0241H

Check of Concentration Limit

Contents

Explanation of indications

Explanation of illustrated marks

Confirmation of warning label on the main unit

Indication Explanation

∗ For details, refer to the parts list

Never recover the refrigerant into the outdoor unit

Do not modify the products

For spare parts, use those specified ∗

Check the following items after reinstallation

Metal section Earth position

Side

Limit even if the refrigerant leaks

Safety Caution Concerned to New Refrigerant

New Refrigerant R410A

Pipe Materials

Tools

Recharge of Refrigerant

Environmental concern

4mm-hexagonal wrench is required

Cylinder with siphon Cylinder without siphon

Operation mode

Operation mode Outline

Component Multi Using High-efficiency Refrigerant R410A

Outdoor units

Combination of outdoor units

Branching joints and headers

Flow selector units FS unit

Indoor units

RBM-Y1121FE

RBM-Y1801FE

MMD-AP0241H

Remote controllers

Indoor

Unit

Way

Air Discharge Cassette Type

AP0241WH, AP0271WH, AP0301WH AP0071WH, AP0091WH, AP0121WH

AP0481WH AP0151WH

AP0181WH

Indoor control P.C. board

Compact type

AP0071YH, AP0091YH, AP0121YH

Color

Indication

Symbol Parts name

Model MMU-AP0151SH, AP0181SH, AP0241SH

Network adapter

Option

Symbol Parts name

Way Air

Concealed

Duct Standard Type

AP0481BH, AP0561BH

AP0241BH

Symbol Parts name

Concealed Duct High Static Pressure Type

Model

MMD-AP0181H, AP0241H, AP0271H, AP0361H

Under

Ceiling Type

AP0241H, AP0271H, AP0361H

AP0151H, AP0181H

High Wall Type

AP0121H, AP0151H, AP0181H, AP0241H

Model MMK-AP0071H, AP0091H

AP0122H

Model MMK-AP0072H

AP0092H

Floor Standing Cabinet Type

AP0151H, AP0181H, AP0241H

Model MML-AP0071H, AP0091H, AP0121H

Color

Floor Standing Concealed Type

Model MML-AP0071BH, AP0091BH, AP0121BH

AP0151BH, AP0181BH, AP0241BH

Color indication

Symbol Parts name

AP0241H, AP0271H, AP0361H, AP0481H, AP0561H

Model MMF-AP0151H, AP0181H

Color

Model MMD-AP0071SPH

AP0091SPH, AP0121SPH,AP0151SPH

For undoor unit

Color indication

Outdoor Unit

Model MMY-MAP0801FT8

MAP1001FT8, MAP1201FT8

Parts layout

Flow Selector Unit FS

Model RBM-Y1122FE, Y1802FE, Y2802FE

Indoor Unit

Way Air Discharge Cassette Type

Way Air Discharge Cassette Compact type Type

Concealed Duct Standard Type

Concealed Duct High Static Pressure Type

Slim Duct Type

Under Ceiling Type

High Wall Type

Floor Standing Cabinet Type

Floor Standing Concealed Type

Floor Standing Type

Heat Recovery Model

Outdoor Control Unit

Flow Selector Unit FS Unit

MAP0802FT8 MAP1002FT8 MAP1202FT8

Parts Layout in Outdoor Unit

Front side Rear side

Name of Each Part

Indoor Unit

Sold Separately Parts

Parts Name of Remote Controller

Outdoor Unit

Display section

Correct Usage

Operation section

Preparation

Stop

Adjustment of Wind Direction

How to set up the air direction

How to start louvre swinging

How to stop louver swinging

How to set up the air flow direction

How to start swinging

How to stop swinging

Adjustment of air direction upward/downward

Right/Left air direction adjustment

Adjustment of air Flow direction Upwards/Downwards

Adjustment of air Flow direction rightwards/leftwards

Setup of air direction and swinging

Timer Operation

Timer operation

Cancel of timer operation

Installation

Maintenance

Cleaning the air inlet grille

Cleaning of main unit / remote controller

High Wall Type Model 1H series

Model 2H series

Air Conditioner Operations and Performance

Re-Installation

When the Following Symptoms are Found

Air conditioner operating conditions

Confirmation of error history

Procedure Description

Confirmation and check

Inverter Unit 8, 10, 12HP

Model MMY-MAP0802FT8, MAP1002FT8, MAP1202FT8

Explanation of Functional Parts

Functional part name Functional outline

Operation mode

Operation mode Outline

SVD

SVS

Svdd

Svss

TC1

TC2

TCJ

Refrigerant Piping Systematic Diagram in System

Selection of operation mode

ON-OFF list of Flow Selector Unit FS Unit valve

High outside temperature 10C or more Criterion

All cooling operation Operation of cooling only

Outdoor unit

Flow selector/Indoor unit Cooling thermo.-ON Stop

Low outside temperature 15C or less Criterion

OFF SV3E

Cooling thermo.-ON Stop

Flow selector/Indoor unit

All heating operation Operation of heating only

SV3B SV5 OFF SV3C SV6

Flow selector/Indoor unit Heating thermo.-ON

Heating thermo.-OFF

Mainly Cooling, Partly Heating Operation

Heating thermo.-ON

Mainly Heating, Partly Cooling Operation

Outdoor unit Flow selector/Indoor unit

Cooling thermo.-ON Heating thermo.-ON Stop

Defrost

Flow selector/Indoor unit Cooling thermo.-ON Others

Control Specifications

Outline of specifications Remarks

Remote controller Control outline Command

Allcooling All heating

Reset conditions

TC1

TCB-AX21E

Central control mode 1 Cannot operate

Central control mode

Central control mode 4 Cannot select mode

Operation Start/Operation End

Operation explanation and applied data, etc Remarks

Oil SV2

Operation explanation and applied data, etc Remarks

Operation explanation and applied data, etc Remarks

Ipdu

Cooling operation in low ambient temperatures

Other cautions

Release control list

PMV Pulse Motor Valve for outdoor unit

Oil equation control schematic diagram

Header outdoor unit MMY-MAP1202FT8 Unit to send oil

Follower outdoor unit MMY-MAP1202FT8 Unit to

Received oil

Procedure Execute the setup operation while the unit stops

Every pushing

Description At shipment

HEAT, Heat → Cool

Indoor unit capacity

Item code

How to Set Up the Cooling Only Indoor Unit

Setup data

Cooling Only setup Heat pump

Description

Setting When Connecting Multiple Indoor Units to a FS unit

Usage/Features

How to set up Item code

Push Vent + Test buttons simultaneously for Seconds or more

Case of not setting 01 to Item code 0E

SVS OFF

SVD OFF

SVD OFF Svdd SVS

Wiring and setup

Wiring diagram using remote control interface TCB-IFCB-4E

Applied Control in Indoor Unit

Remote location ON/OFF control box TCB-IFCB-4E

Ventilating fan control from remote controller

Wiring

Function

Operation

Using the timer time

Using the setup temp

Button, set to the setup data

Leaving-ON prevention control

Applied Control in Outdoor Unit

Outdoor fan High Static Pressure Shift

Outdoor unit interface P.C. board Connector position detail

Function Switch No Bit Connector No Used control P.C. board

Power Peak-cut Control Standard

Setup when Power peak-cut control requested

Relay contact capacity of operation port

Outdoor unit interface P.C. board

Power Peak-cut Control Expansion

Setup at power peak-cut control expansion request

SW1 SW2

CN513

Input signal Operation

Terminal Input signal Operation

Snowfall Fan Control

External master ON/OFF control

Operation Mode Selection Control

Night Operation Control

Cool OFF

Night operation sound Capacity Reduction dB a

Procedure and Summary of Test Operation

Main check items for electric wiring

Check Items before Test Operation

Case that a center control

Check list

Additional amount of refrigerant by pipe length

Corrective amount of refrigerant by system capacity

Additional amount of refrigerant

Check at Main Power-ON

Address Setup

Address Setup and Check Procedure

Check on outdoor unit

Address Setup Procedure

Address setup procedure

Line address switch on outdoor interface P.C. board

Turn on the power Wiring example in 2 lines

Operation procedure

Push SET button

Group address

Using Unit + SWING/FIX buttons, select the line Address

Using the setup temp

Using

Button to Operation procedure Confirm the changed contents

Push SET button to determine the setup data

Push Test button to finish the procedure

End

Displayed. Only fan of the selected indoor unit operates

Setup procedure

SW01 SW02 SW03 SW04

Troubleshooting in Test Operation

Check Code is Displayed on the Remote Controller

Check code

Cause Countermeasures

Remote Segment

Cause Countermeasures

Status Cause Countermeasures

Display

Incorrect wiring example Fig

Remote Header unit Incorrect example

Controller status Segment display

Status Incorrect example

Test Operation Check

Fan Operation Check

Cooling/Heating Test Operation Check

Test operation start/stop operation

Wireless remote controller

Turn OFF the power to the air conditioner

Button on the wireless remote controller

Test operation from outdoor unit

Procedure Description

Test cooling operation Test heating operation

Test operation

100

101

Service Support Function

Function Outline Setup/Release Segment display

Function to Start/Stop ON/OFF Indoor Unit from Outdoor Unit

102

Operation procedure

All cooling test operation function

All heating test operation function

103

Batch start/stop ON/OFF function

104

105

SW01 SW02 SW03 Units to be operated

Error Clearing Function

Error clearing in indoor unit

Method

Section a

Clearing of error check code by power reset

Clearing from the interface P.C. board

107

Remote Controller Distinction Function

Distinction procedure

108

Operation

Solenoid Valve Forced Open/Close Function in Outdoor Unit

Clear

110

Heater

Fan Operation Check in Outdoor Unit

111

SW01 SW02 SW03

Fan step

Release

Case to operate the fan in the erroneous outdoor unit only

Case to operate the fans in all the normal outdoor units

112

Manual Adjustment Function of Outside Temp to Sensor

Service support function list

Function contents

113

Indoor Fan Only Operating Mode

Indoor Fan Operation Check Function

114

Monitor Function of Remote Controller Switch

Contents

Procedure

Calling of display screen

Troubleshooting Summary

Before troubleshooting

Troubleshooting procedure

116

Check code list

Check Method

117

118

Error detected by TCC-LINK central control device

119

Main Outdoor 7-segment display Sensor block display

Device

New check code

Troubleshooting by Check Display on Remote Controller

Case of wired remote controller RBC-AMT31E

Confirmation of error history

Confirmation and check

Case of central remote controller TCB-SC642TLE

122

Case of AI-NET central remote controller

Error detection condition Check item position

124

Check code

Check code name

Error detection condition Check item position

Setup method of No. capacity-over detection

125

Convenient functions

Status Error detection condition Check item position

126

Outdoor 7-segment display

127

128

Detected Check code name

Error detection condition

129

Status

Check all the outdoor units in the corresponding line

130

131

Check code Detected Main Outdoor 7-segment display

Remote Central control Controller Check code

132

Name

133

Heating

Check code Status Error detection Check item position

134

Name Condition

135

Sub-code C

Sub-code D

Sub-code E

136 Error detected by TCC-LINK central control device

Error detected by AI-NET central control device

Error detection Check item position

Controller

How to check inverter output

How to check resistance of compressor winding

How to check the outdoor fan motor

137

Diagnosis Procedure for Each Check Code

138

139

E06

E07

Detected at outdoor side

140

141

E16

E18 / 97/99

E19

142

Indoor TCJ sensor error

Indoor TC2 sensor error

F03 Indoor TC1 sensor error

143

144

145

H02 / 1d Compressor error Lock

F31 / 1C

H01 / 1F

146

147

H14 Compressor 2 case thermo operation

H06 Low-pressure protective operation

148

Low oil level protection

Leakage check for SV3C valve

Clogging check for SV3E valve

149

TK3 temperature detective circuit error

150

151

L05

L03

L06

152

L18 / 8A Flow selector unit system error

153

L20

L28

L31 Extended IC error

P01 Indoor fan motor error

154

L30 / b6

P05 / AF Open phase, negative phase

155

P04 Actuation

High-pressure SW

P07 / 1C Heat sink overheat error

P10 / 0b Indoor overflow error

Indoor fan motor error

156

P13 Outdoor liquid back detection error 1. PMV1/PMV2 error

157

P15 / AE

Gas leak detection

P17 / bb Discharge temp TD2 error

158

P15 / AE Gas leak detection

TD condition Sub-code

P19 Way valve operation error

159

P20 High-pressure protective operation

Judgment criteria

P22 / 1A Outdoor fan Ipdu error

160

P26 Tr short-circuit protection error

Detective circuit error

161

P29 Compressor position

162

How to read the check display Segment display

Segment Display Function

Segment display on the outdoor unit Interface P.C. board

163

SW01 SW02 SW03 Display contents

164

165

166

SW03 SW02 Indoor address Segment display a

Sensor Characteristics

Temperature sensor characteristics

Outdoor Unit

Segment display A, B

Pressure sensor characteristics

Lead wire color

Indoor Unit

168

Pd sensor characteristics

Pressure Sensor Output Check

169

MPa Kg/cm²

Ps sensor characteristics

170

Flow Selector Unit FS Unit

171

172

May become

Detection Flow Almost normal Cooled

Reference

173

Refrigerant

Indoor Controller Block Diagram

Wired remote controller

Weekly timer

Series

Wired remote controller Up to 2 units

Weekly timer

175

176

Slim DuctType

Series

177

Wired remote controller

178

SlimDuctType

179

Indoor P.C. Board

MCC-1402

Type

181

Eeprom

Disp

CHK

Flow Selector Unit P.C. Board

MCC-1431-01

182

Optional Connector Specifications of Indoor P.C. Board

Function Connector Pin Specifications Remarks

183

DC12V COM

184

SV3D SV3E

Uart

RMV

Inverter P.C. board MCC-1502 IPDU1, IPDU2

185

Power supply P.C. board for fan MCC-1439

186

Part type Exchange contents

187

Before Backup Operation

Compressor Backup Setup

Procedure

Outline

Backup Setup for Outdoor Unit

Set up procedure for the malfunctioning outdoor unit

189

Operation procedure

Display example

Segment display oil level results

190

Refrigerant Recovery in the Malfunctioning Outdoor Unit

Before Refrigerant Recovery Operation

Refrigerant Recovery Procedure

Set up the malfunctioning outdoor unit as follows

Select an outdoor unit for pressure adjustment as follows

Set up all other outdoor units as follows

Setup for outdoor unit for adjustment of pressure

192

Refrigerant recovery procedure backup

Set up the unit selected as the header unit as follows

193

Setup for header unit

194

Refrigerant amount to be recovered = 37.5 28.0 = 9.5 kg

195

System Combination of outdoor units Refrigerant amount

Process after Repair

196

Trouble by leakage

197

Unit issuing Check code to be detected Phenomena

Check code Corresponding unit

198

Compressor Replacing Procedure Outline

Never recover the refrigerant into outdoor unit

199

Replacing Compressor

Exchanging a compressor

Removal of defective compressor

200

Color check of oil in the defective compressor

201

Adjustment of oil amount in the service compressor

Measurement of oil amount in the normal compressor

202

Installation of compressor

Vacuuming Case of single outdoor system

Case of multiple outdoor unit systems

Full opening of PMV1, PMV2

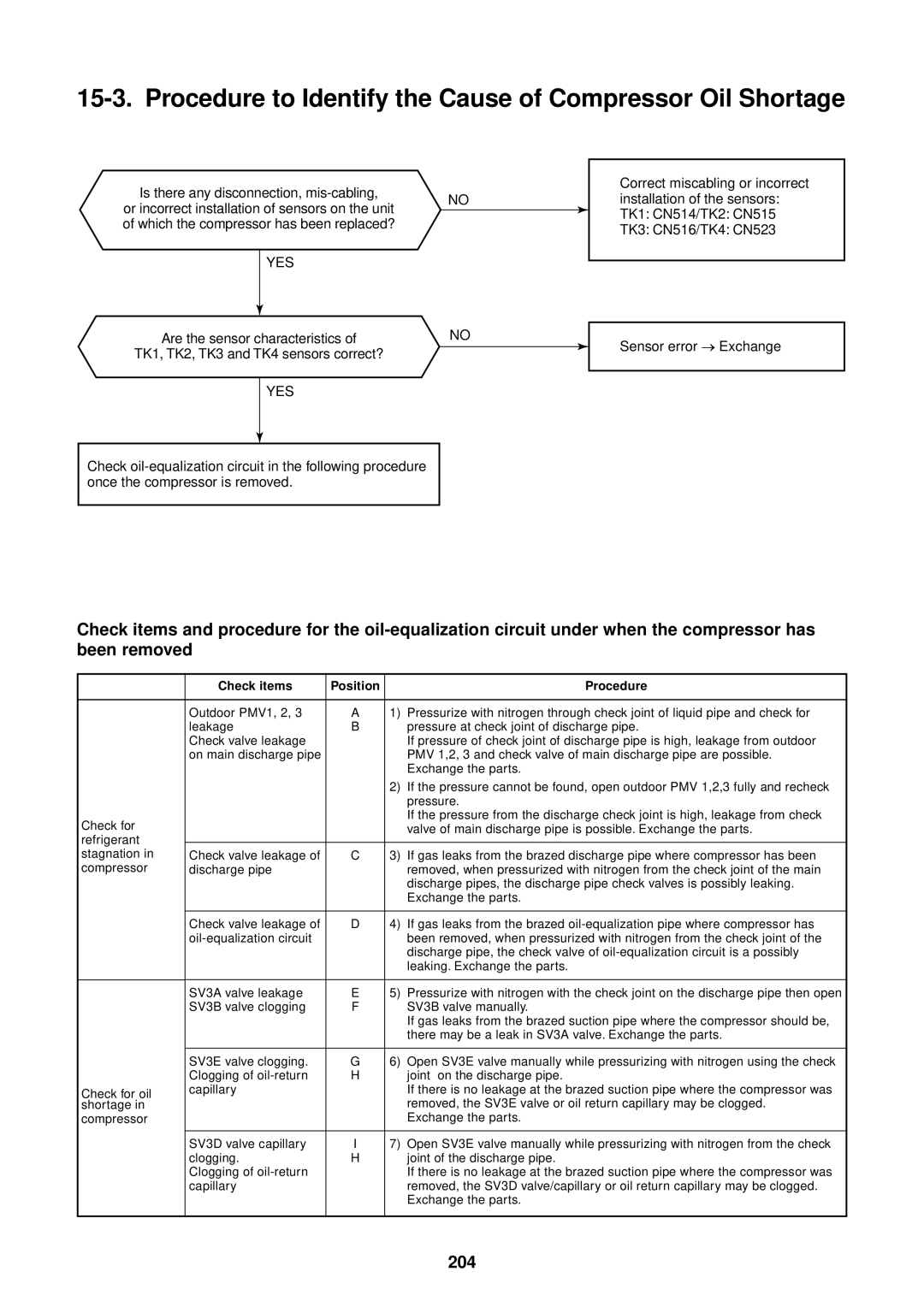

Procedure to Identify the Cause of Compressor Oil Shortage

Check items Position Procedure

204

205

Nitrogen

Pressure

Reassembly

206

Remarks

Disassembling

Work procedure Remarks

207

Fan motor

Part to be

208

Disassembling Example

Heat exchanger Right

Reassembly and cautions

209

Inverter assembly

Exchange of service P.C. board

210

211

Work procedure

Temperature Front side of air conditioner sensor posi

212

SV3C SV3A SV3B

Temperature Rear side of air conditioner

213

Used positions of SUS fixing band Total 5 positions

Assembly

214

215

Pull the accumulator upwards

216

Exchange of P.C. Board for Indoor Service

Exchange procedure

217

Procedure 1 Readout setup contents from Eeprom

Remote controller operation diagram

Procedure 2 Exchange of P.C. board for service

219

Procedure 3 Writing-in of setup contents to Eeprom

Eeprom layout

Type Indoor unit capacity Item code

221

How to Check Inverter Output

How to Check Outdoor Fan Motor

How to check resistance or compressor winding

Part name Procedure

How to Check Fan Power Supply P.C. Board and Fan Ipdu

How to check fan power supply P.C. board MCC-1439

How to check fan Ipdu

MCC-1439 Front View

Interface Board Replacement Procedure

Replacement steps

Dip Switch Setting contents

224

Comp-IPDU Board Replacement Procedure Manual

225

Comp-IPDU No SW801 Bit

226

COMP-IPDU No.1

COMP-IPDU No.2

Inverter Assembly Configuration

227

Toshiba Carrier Corporation