Page

Page

Page

Preface

Page

Table of Contents

Keypad and Start Up

Troubleshooting

Parameters

Appendix a Specifications Appendix B Accessories

Fault Code Information and Maintenance

Appendix C How to Select the Right AC Motor Drive

Nameplate Information

Receiving and Inspection

Model Explanation

20HP/5.5-15kWFrame C 25-40HP/18.5-30kWFrame D

Series Number Explanation

Drive Frames

Appearances

Introduction

Remove Instructions 1.3.1 Remove Keypad

Remove Front Cover

Introduction

Lifting

Step

For 250-300HP Frame H

Storage

Preparation for Installation and Wiring Ambient Conditions

Minimum Mounting Clearances

Operation

Introduction

Frame

Dimensions

425.016.73 381.015.00 850.033.46 819.532.26

This page intentionally left blank

Installation and Wiring

Wiring

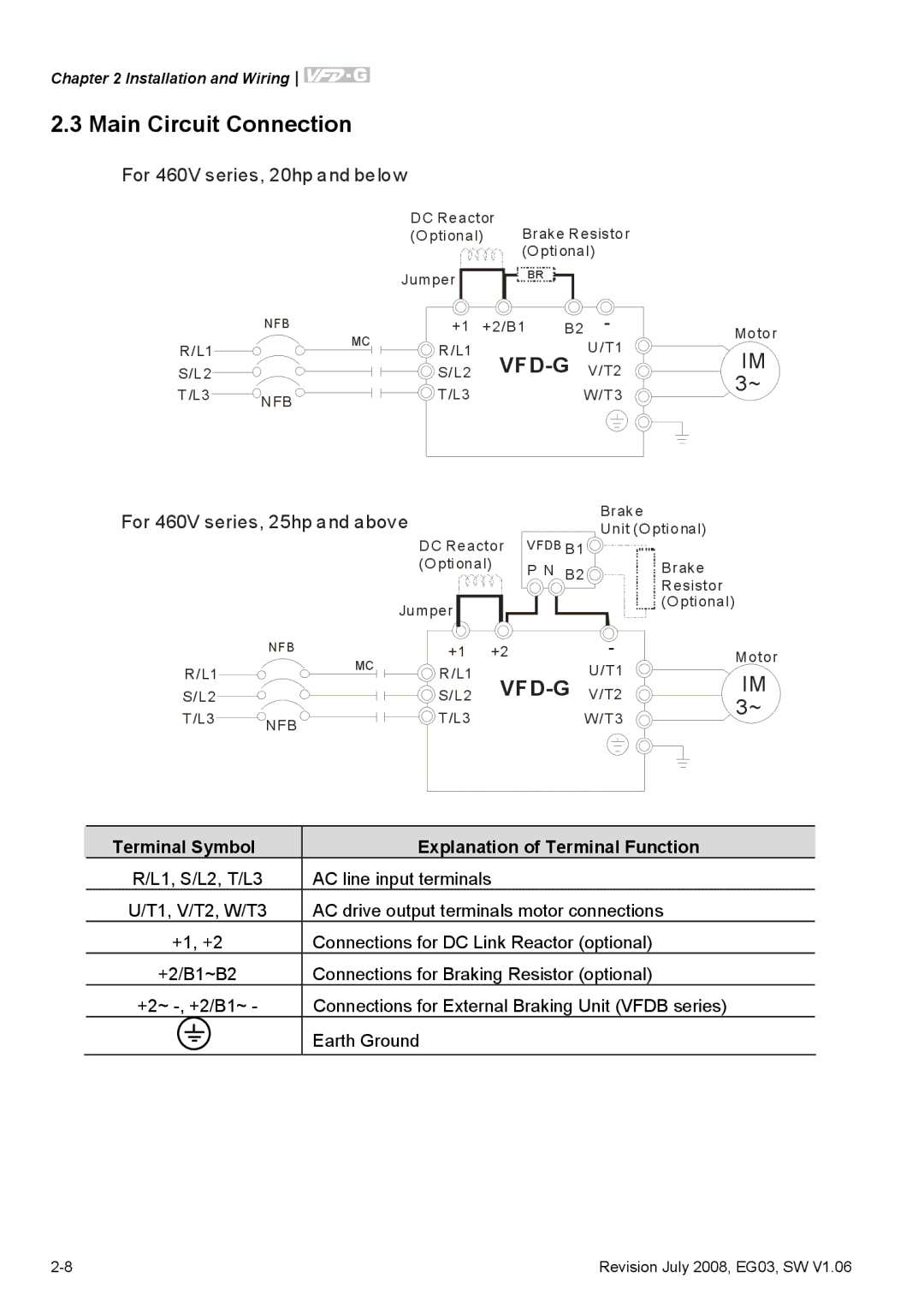

VFD-G

For 460V series, 25hp and above

Wiring for Sink mode and Source mode

Sink Mode

Excellent Good Not allowed

FUSE/NFB

External Wiring

Main Circuit Connection

Terminal Symbol

Explanation of Terminal Function

Terminals +1, +2+2/B1 for connecting DC reactor

Mains power terminals R/L1, S/L2, T/L3

Output terminals for main circuit U, V, W

Vfdb

MI4

Control Terminals

Relay outputs RA1, RB1, RC1

Analog inputs AI1, AI2, AC1, AC2

General

Power Motor

HP to 40 HP VFD185F43A-G, VFD220F43A-G, VFD300F43A-G

HP to 60 HP VFD370F43A-G, VFD450F43A-G

HP to 125 HP VFD550F43A-G, VFD750F43A-G, VFD900F43C-G

HP to 215 HP VFD1100F43C-G, VFD1320F43A-G, VFD1600F43A-G

HP to 300 HP VFD1850F43A-G, VFD2200F43A-G

Wiring Explanation for Analog Input Terminal

Installation and Wiring

This page intentionally left blank

Display Message

Digital Keypad VFD-PU01 Description of the Digital Keypad

Descriptions

Display Message Descriptions

How to Operate the Digital Keypad VFD-PU01

Reference Table for the LED Display of the Digital Keypad

VFD-PU01 Dimensions

Operation Method

RUN Stop

Trial Run

This page intentionally left blank

Parameters

Group 0 User Parameters Functions Settings Factory Customer

Summary of Parameter Settings

Parameter Functions Settings Factory Customer

Setting

Parameter Functions Settings Factory

Group 1 Basic Parameters Functions Settings Factory

= coast to stop

Parameter Functions Settings Factory

Parameters

Parameters

04-24 Analog Input Delay 00~10.00 Sec

Execute one program cycle step by step

Time Duration Step To 65500 Sec / 0.0~6550.0 Sec

Parameter Functions Settings Factory

Parameter Functions Settings Factory Customer

Setting

Parameter Functions Settings Factory Customer

Parameter Functions Settings Factory Customer

Parameters

DC Brake before Running Applications Purpose Functions

Parameter Settings for Applications

Multi-step Operation Applications Purpose Functions

Frequency Hold Applications Purpose

Two-wire/three-wire Applications Purpose

Operation Command Applications Purpose

Auto Restart after Fault Applications Purpose

Parameters

Parameters

Multi-function Analog Output Applications Purpose Functions

Group 0 User Parameters

Description of Parameter Settings

Fanp

Parameters

00 14 PLC Time

Group 1 Basic Parameters

01 04 Mid-point Voltage Settings 2V~510.0V

Parameters

Unit 0.1sec

Parameters

Group 2 Operation Method Parameters

PWM Carrier Frequency Selections Settings ~10HP 4000~6000Hz

VFD-G

02 07 Reserved

Flying Start Factory Setting

Group 3 Output Function Parameters

Setting Functions Descriptions

Frequency 2Hz

03 04 DC Fan Control

Parameters

Group 4 Input Function Parameters

Setting Functions Descriptions

Parameters

Max AI1*AI1 Gain, AI2*AI2 Gain

Factory Setting

Group 5 Multi-step Speed Parameters

05 15 PLC Mode

Example 2 Pr.05-15 = 2 Continuously executes program cycles

Example 3 Pr.05-15 = 3 Execute one cycle step by step

Bit 0 1 0 0 1 1 1 1 1

Parameters

Frequency

Group 6 Protection Function Parameters

Time

06-01

06 03 Over-torque Detection Selection

80 100 120 140 160 200

Parameters

Delta

18.5 110 132 160 185 220

Group 7 AC Drive and Motor Parameters

Parameters

Parameters

Accumulated Electric Bill per currency unit

Group 8 Special Parameters

DC Braking Time

Momentary Power Loss Operation

Output frequency

Parameters

100% 70%

Parameters

Group 9 Communication Parameters

None parity + 2 stop bit

GND 3 SG- 4 SG+ 6 for communication

Start Stop Stop

RTU mode

Ascii mode

Command message Response message Error response message

CDH

C6H

High

RTU mode Command message

0FH

‘0’ ‘1’

ADR CMD

BB OFF

Content Address Function

Rev LED is on and FWD led is off. Reverse

LRC CHK

Communication time-out

Group 10 PID Control Parameters

Parameters

Determined by group

Curve Diagram

This page intentionally left blank

Over Current OC

Troubleshooting

Over Voltage OV

Ground Fault

Low Voltage Lv

Overload

Over Heat OH

Keypad Display is Abnormal

Phase Loss PHL

Motor cannot Run

Motor Speed cannot be Changed

Motor does not Run as Expected

Motor Stalls during Acceleration

Environmental Condition

Electromagnetic/Induction Noise

Affecting Other Machines

Serial reactor Phase lead capacitor

Common Problems and Solutions

Fault Code Information

Fault Fault Descriptions Corrective Actions Name

Ensure that the ambient temperature falls within

Fault Fault Descriptions Corrective Actions Name

Fault Fault Descriptions Corrective Actions Name

Periodic Inspection

Reset

Maintenance and Inspections

Daily Inspection

Voltage Maintenance Check Items Methods and Criterion

Main circuit Maintenance Check Items Methods and Criterion

Keypad Maintenance Check Items Methods and Criterion

Change of copper plate

One

One Year

Daily

Appendix a Specifications

Appendix a Specifications

All Brake Resistors & Brake Units Used in AC Motor Drives

Appendix B Accessories

Appendix B Accessories

VFD Series

Non-fuse Circuit Breaker Chart

Fuse Specification Chart

AC Reactor

AC Input Reactor Recommended Value 460V, 50/60Hz, 3-Phase

460V DC Choke

AC Output Reactor Recommended Value

460V, 50/60Hz, 3-Phase

Applications

Correct wiring

Reduce harmonics and provide protection from

Diagram a

Zero Phase Reactor RF220X00A

Diagram B

Explanation of Display Message

PU06 Description of the Digital Keypad VFD-PU06

XX-XX

3 PU06 Operation Flow Chart

Related Specification

Appendix C How to Select the Right AC Motor Drive

When one AC motor drive operates more than one motor

When one AC motor drive operates one motor

Capacity Formulas

Symbol explanation

Parameter Settings Note

General Precaution

Selection Note

Standard motor

How to Choose a Suitable Motor

Pole-changing Dahlander motor

Special motors

Motor torque

Power Transmission Mechanism

This page intentionally left blank

![]()

![]()

![]()

![]()

![]()

![]()