Instructions Parts

Important Safety Instructions

Contents

Appendix a Advanced Display Module ADM

Appendix D I/O Signal Descriptions

Technical Data

Related Manuals

Description Regulator

Models

Style/Size Fluid Plate

Voltage

Description Tor

Fluid Plate Kits

Includes Fluid Used by

Regula Flow FCM Key Plate Kit Model

Expansion Swirl Enclosure Assemblies

PrecisionSwirl Orbital Dispenser Assemblies

PrecisionSwirl Orbital Dispenser Cable Assemblies

Swirl Control DGM

Automation Gateway Assemblies

Electric Shock Hazard

Equipment Misuse Hazard

System Configurations

Typical Installation Single Swirl, Single Fluid Plate

IG Typical Ambient System Installation Key

Typical Multiple Fluid Plate System Installation Key

Typical Multiple Fluid Plate System Installation Key

Overview

System Overview

System Components

Fluid Plate Assembly Overview

Ambient Fluid Plate Assembly

Heated Fluid Plate Assembly

Connection Sensor Description

Rotary Switch

Fluid Regulator

Fluid Control Module FCM

Front View Side View

Control Center Assembly Overview

Expansion Swirl Enclosure

Front View

See LED Diagnostic Information, page 65, for

Advanced Display Module ADM

Callout Function

Discrete Gateway Module DGM Connection

Front Back Access Cover Removed

Gateway Module Connectors

Automation Gateway Module

Front Back

DGM Function Rotary Switch Position

Front Access Cover Removed

Swirl Control DGM

Admfcm

Key Tokens

Overview

Installation

Before Installation

Installation Steps

Install Control Center

Control Center Assembly Measurement

Mount

Connect Light Tower Accessory

Light Tower Signals Description

Electrical Connections

Mount Assembly

Install Fluid Plate Assemblies

Fluid Plate Assembly Measurement

Before Mounting Assembly

Cable for Connection Labeled

Mount Four-Valve Breakout Kit 24B693

Custom Breakout Cable

Connects to Splitter

FCM

Install Command Cable Kit 24B694

Dispense Valve

Ground

Connect Fluid and Air Lines

Air and Fluid Hoses

Install Cable Assemblies

Cable Installation Diagram

Module Description

Install Gateway Module Interface

CGM Status LED Signals Description

Fieldbus Communications Gateway Module

Discrete Gateway Module

DGM Rotary Switch Position

Configure System

System Setup

Configure Control Settings

Configure Delay Settings

Configure Mode Settings

Set Flow Meter K-Factor

Configure Flow Meter Settings

Configure Pressure Loop Settings

Flow Meter K-Factors Part Description

Configure Errors

Adjust Pressure Sensors

To set limits

Setup Maintenance Schedule/Parameters

Configure Valve to Swirl Association and Motor Error Type

To reset a totalizer value

Configure Advanced Settings

Configure Swirl Settings

Configure Gateway Settings

Setup Styles

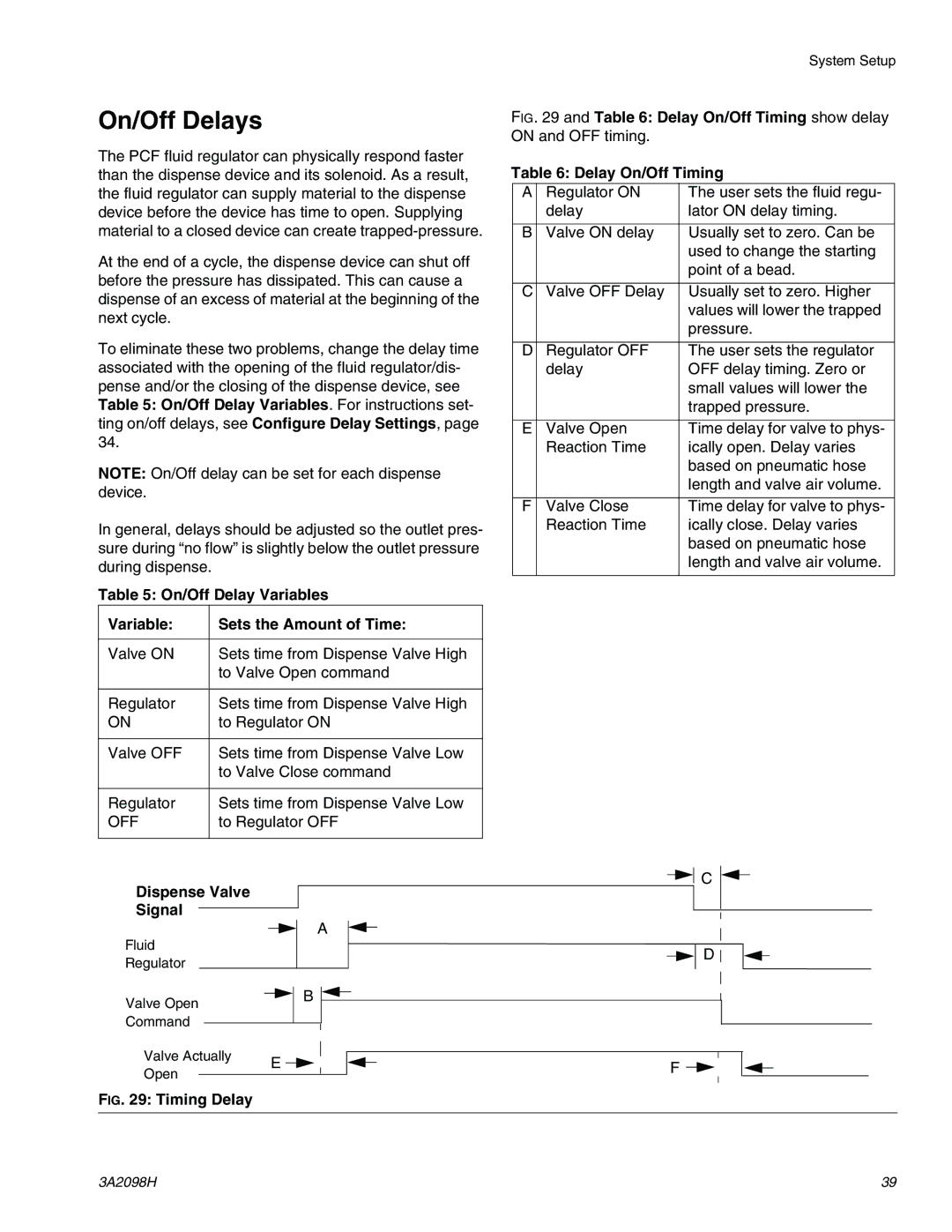

On/Off Delay Variables Sets the Amount of Time

On/Off Delays

Delay On/Off Timing

On/Off Delay Variables. For instructions set

Initial Startup

Operation

Startup

Load Material

Feed System Pressure Drop

Maintenance Mode Operation

Verify System Operation

Set Inlet Pressure

Verify Flow Meter Calibration

Dispense from Each Valve

Manually Adjust Control Loop Parameters

Dispense From Maintenance Screen

Manually Dispense Fluid

Operate Swirl Dispenser From Maintenance Screen

Jobs

Jobs in Bead Mode

Jobs in Pressure Mode

Automation Control Normal Operation

Styles

To setup a style

Static Precharge Mode

Precharge Modes

Dynamic Precharge Modes

Closed Precharge Scaling Value

Typical Job Cycle

Jobs with Command Cable Dispense Trigger

Automation Inputs PCF Outputs

Typical Job Cycle Chart

Control Charts

Purge Using Style

Purge Using Purge Bit

Error Reset

Cancel Job

Remote Start

Precharge* Gateway Mode

Precharge* Display Mode

Trigger Using Command Cable

Precharge* Valve 1 Mode

Trigger Using Command Cable and Gateway Combined

Trigger Using Gateway

Enable Swirl Dispenser

Dispense Valve Air Solenoid

Pressure Relief Procedure

Shutdown

Follow the Pressure Relief Procedure on

Job Log

USB Data

USB Logs

Event Log

System Configuration Settings File

Custom Language File

Create Custom Language Strings

Download Procedure Upload Procedure

Problem Cause Solution

Troubleshooting

Flow Meter

Dispense Valves

Gateway Module

LED Diagnostic Information

Diagnose Errors

View Errors

Event and Error Codes and Troubleshooting

System Events and Errors

Control Center Events and Errors

Fluid Plate Events and Errors

WND

WED

WSD

WSD5

WXD

WFD

WFG

EJD

EHD

EKD

Refer to Fluid Plate

Assembly Overview

Errors

Refer to Swirl Control

Swirl Events and Errors

Electrical

Maintenance

Maintenance Schedule

Mechanical

Advanced Display Module ADM

Upgrade Gateway Module Software

Upgrade Software

Cleaning

Upgrade Gateway Module Fieldbus Map

Upgrade Fluid Control Module FCM Software

Air Filter Maintenance

Swirl Dispensers

Remove Flow Meter from Mounting Plate

Fluid Plate Assembly

Repair

Repair Flow Meter

Install Flow Meter on Mounting Plate

Replace Solenoid

Replace Voltage to Pressure V/P Transducer

Replace Fluid Control Module

Replace Transducer O-Rings

Cartridge Regulator 244734 Shown

Repair Fluid Regulator

Adjust Display Settings

Replace Amplifier

Calibrate Amplifier

Adjust Amplifier Settings

To Readout

To Transducer

Control Center Assembly

Prepare Control Center for Repair

Replace Gateway Module

Replace Advanced Display Module

Replace Swirl Board 16K570

Replace DIN Rail Assembly

Replace Fuses

24 Vdc Din Rail Assembly

Control Centers

Parts

Ground Neutral Line Green Blue Brown

Control Center and Expansion Swirl Enclosure Parts

Part Description Qty

Control Center Assembly Parts

Fluid Plate Assembly Parts

Fluid Plate Assembly Parts

Fluid Plate 24B962 Shown

Fluid Plate Key Token Part Numbers

Spacer

No Meter

Parts Varying by Assembly

Fluid Plate Assemblies Heated Mastic Cartridge

Regulator Heated Cartridge

Appendix a Advanced Display Module ADM

Display Overview

Display Details

Navigation within Screens

Soft Keys

Setup Mode

Advanced Setup Screens

Advanced Setup Screen

Gateway Setup Screen 2 EtherNet/IP

Automation Gateway Setup Screens

Gateway Setup Screen 1 DeviceNet

Gateway Setup Screen 1 EtherNet/IP

Gateway Setup Screen 2 Profinet

Gateway Setup Screen 1 Profibus

Gateway Setup Screen 2 Profibus

Gateway Setup Screen 1 Profinet

Discrete Gateway Automation Setup Screen

Fluid Plate Setup Screens

Fluid Plate x, Screen 1 Control Settings

Fluid Plate x, Screen 2 Mode Settings

Fluid Plate x, Screen 4 Control Loop and Flowmeter Settings

Fluid Plate x, Screen 3 Delay Settings

Fluid Plate x, Screen 5 Pressure Sensors

Fluid Plate x, Screen 6 Error Type

Fluid Plate x, Screen 8 Style

Fluid Plate x, Screen 7 Maintenance Advisory Limits

Swirl Setup Screen

Keyboard Screen

Fluid Plate x, Screen 9 Swirl Association

Run Mode

Fluid Plate Home Screen

Swirl Home Screen

Systems with flow

Current Command Value Active Dispense

Fluid Plate x, Screen

Flow Rate

Dispense Control Modes

Maintenance Mode

Fluid Plate x, Screen 2 Control Center

Fluid Plate x, Screen 3 Maintenance Totalizers

Event Report Screens

Error Report Screens

Swirl X Screen

Job Report Screens

Appendix B Discrete Gateway Module DGM Connection Details

Wire Color Description Pin Type Sub Pin No

Sub Pin No Description Pin Type Voltage Vdc

Sub Cable 123792 and Breakout Board

Installed fluid plate, no swirl

Pin References

Subminiature Connector Pin References

Isolated Logic ICs

DGM Digital Input

DGM Digital Outputs

DGM Analog Outputs

DGM Analog Inputs

Stop

Install Fieldbus Connections

State Description Comments

RUN

Pin Signal Description

EtherNet/IP

DeviceNet

RTS

Profibus Fieldbus Connections

Input Byte Bit Description Zone

Automation Inputs signals from PCF

See Appendix D I/O Signal Descriptions on

CGM I/O Data Map

See CGM Command Interface on

Output Byte Bit Description Zone

Automation Outputs signals to PCF

O96 Command Value O97 O98

3A2098H 129

Read

Examples

CGM Command Interface

Fluid Plate Commands

Command Interface Timing Diagram

Command Interface Read Operation

Fluid Plate/Swirl Identification Commands

3A2098H 133

GalUk ###### Ume Liters Mass ###### Lb, ###### kg

3A2098H 135

Output Bits Read or 264-275 Description Gateway Units Write

Swirl Commands

Units Definitions

Unit s String Definition

Strxy

Automation Inputs

Appendix D I/O Signal Descriptions

Automation Outputs

Technical Data

Control Center Assembly Technical Data

100 240 Vac Assemblies Vdc Assembly

Fluid Plate Assembly Technical Data

Swirl Dispenser Technical Data

Cartridge Regulator Mastic Regulator

Graco Standard Warranty

Graco Information

Graco Headquarters Minneapolis