To avoid problems when using preprinted forms, embossed paper, and letterhead, observe the following guidelines:

●Avoid using

●Use preprinted forms and letterhead paper that have been printed by offset lithography or engraving.

●Use forms that have been created with

●When the form is preprinted, be careful not to change the moisture content of the paper, and do not use materials that change the paper's electrical or handling properties. Seal the forms in

●Avoid processing preprinted forms that have a finish or coating.

●Avoid using heavily embossed or

●Avoid papers that have heavily textured surfaces.

●Avoid using offset powders or other materials that prevent printed forms from sticking together.

![]() NOTE: To print a

NOTE: To print a

Select the correct fuser mode

The device automatically adjusts the fuser mode based on the media type to which the tray is set. For example, heavy paper, such as card stock, might need a higher

The fuser mode can be changed only if the media type has been set for the tray that you are using. See Control print jobs on page 72. After the media type has been set for the tray, then the fuser mode for that type can be changed on the Administration menu in the Print Quality submenu at the device control panel. See Print Quality menu on page 43.

![]() NOTE: Using the High 1 or High 2 fuser mode setting improves the ability of the toner to adhere to paper, but it might cause other problems, such as excessive curl. The device might print at a slower speed when the fuser mode is set to High 1 or High 2. The table below describes the ideal fuser mode setting for supported media types.

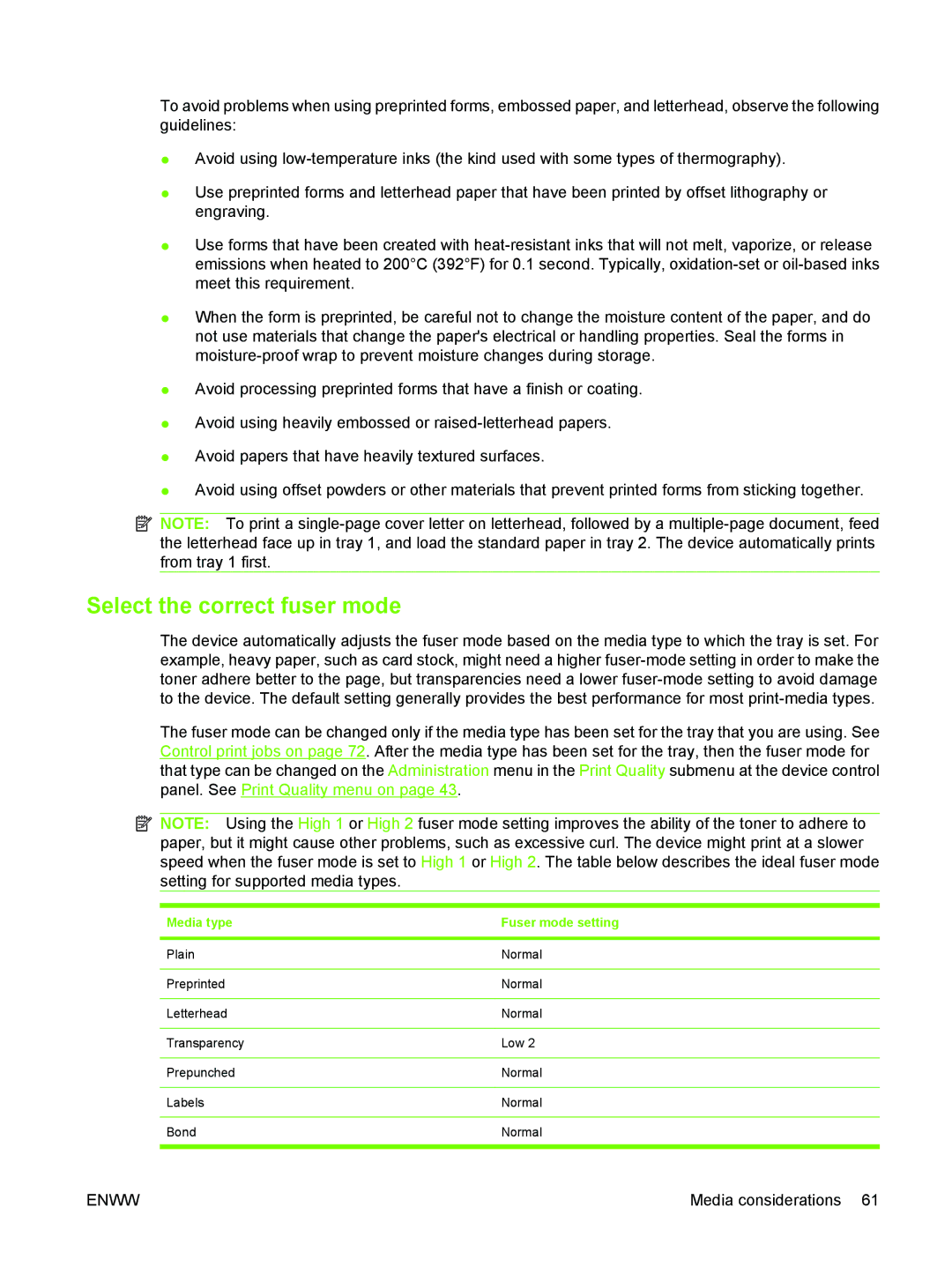

NOTE: Using the High 1 or High 2 fuser mode setting improves the ability of the toner to adhere to paper, but it might cause other problems, such as excessive curl. The device might print at a slower speed when the fuser mode is set to High 1 or High 2. The table below describes the ideal fuser mode setting for supported media types.

Media type | Fuser mode setting |

|

|

Plain | Normal |

|

|

Preprinted | Normal |

|

|

Letterhead | Normal |

|

|

Transparency | Low 2 |

|

|

Prepunched | Normal |

|

|

Labels | Normal |

|

|

Bond | Normal |

|

|

ENWW | Media considerations 61 |