Main code | Sub code |

|

| Content | |

|

|

|

|

|

|

42 | (Note) | Developer counter clear | |||

|

| Used to clear the currently installed developing unit counter and to display the developer counter value on the | |||

|

| copy quantity display. | |||

|

| (“000” is displayed because the counter is cleared.) | |||

|

| (Note) The counter is cleared by entering the sub code “01.” | |||

|

|

|

|

|

|

43 | 01 | Fusing temperature setting | |||

|

| Used to set the fusing control temperature. | |||

|

| When this simulation is executed, the currently set fusing temperature is displayed on the copy quantity display. | |||

|

| The set value is changed by pressing the magnification ratio display key. | |||

|

| Select the fusing temperature and press the PRINT button to store it. | |||

|

| The setting range is 160 ∼ 205°C (in the increment of 5°C). | |||

|

| Only in the | |||

|

| the fusing temperature for duplex copy can be set. The setting procedure is the same as the normal one. | |||

|

|

|

|

|

|

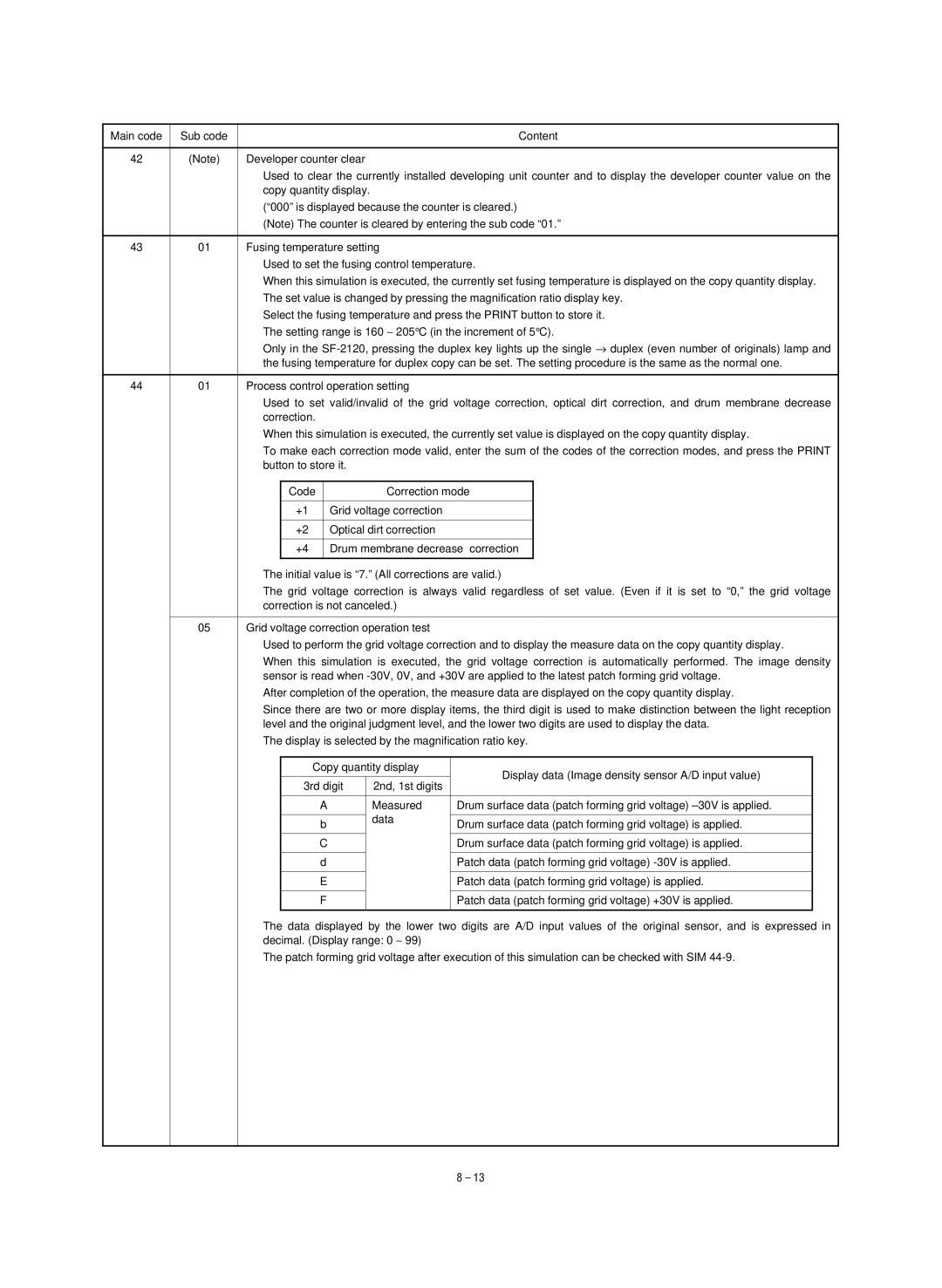

44 | 01 | Process control operation setting | |||

|

| Used to set valid/invalid of the grid voltage correction, optical dirt correction, and drum membrane decrease | |||

|

| correction. |

|

| |

|

| When this simulation is executed, the currently set value is displayed on the copy quantity display. | |||

|

| To make each correction mode valid, enter the sum of the codes of the correction modes, and press the PRINT | |||

|

| button to store it. | |||

|

|

|

|

|

|

|

|

| Code | Correction mode |

|

|

|

|

|

|

|

|

|

| +1 | Grid voltage correction |

|

|

|

|

|

|

|

|

|

| +2 | Optical dirt correction |

|

|

|

|

|

|

|

|

|

| +4 | Drum membrane decrease correction |

|

|

|

|

|

|

|

The initial value is “7.” (All corrections are valid.)

The grid voltage correction is always valid regardless of set value. (Even if it is set to “0,” the grid voltage correction is not canceled.)

05 | Grid voltage correction operation test |

Used to perform the grid voltage correction and to display the measure data on the copy quantity display.

When this simulation is executed, the grid voltage correction is automatically performed. The image density sensor is read when

After completion of the operation, the measure data are displayed on the copy quantity display.

Since there are two or more display items, the third digit is used to make distinction between the light reception level and the original judgment level, and the lower two digits are used to display the data.

The display is selected by the magnification ratio key.

Copy quantity display | Display data (Image density sensor A/D input value) | ||

|

| ||

3rd digit | 2nd, 1st digits |

| |

|

|

| |

A | Measured | Drum surface data (patch forming grid voltage) | |

| data |

| |

b | Drum surface data (patch forming grid voltage) is applied. | ||

| |||

|

|

| |

C |

| Drum surface data (patch forming grid voltage) is applied. | |

|

|

| |

d |

| Patch data (patch forming grid voltage) | |

|

|

| |

E |

| Patch data (patch forming grid voltage) is applied. | |

|

|

| |

F |

| Patch data (patch forming grid voltage) +30V is applied. | |

|

|

| |

The data displayed by the lower two digits are A/D input values of the original sensor, and is expressed in decimal. (Display range: 0 ∼ 99)

The patch forming grid voltage after execution of this simulation can be checked with SIM

8 – 13