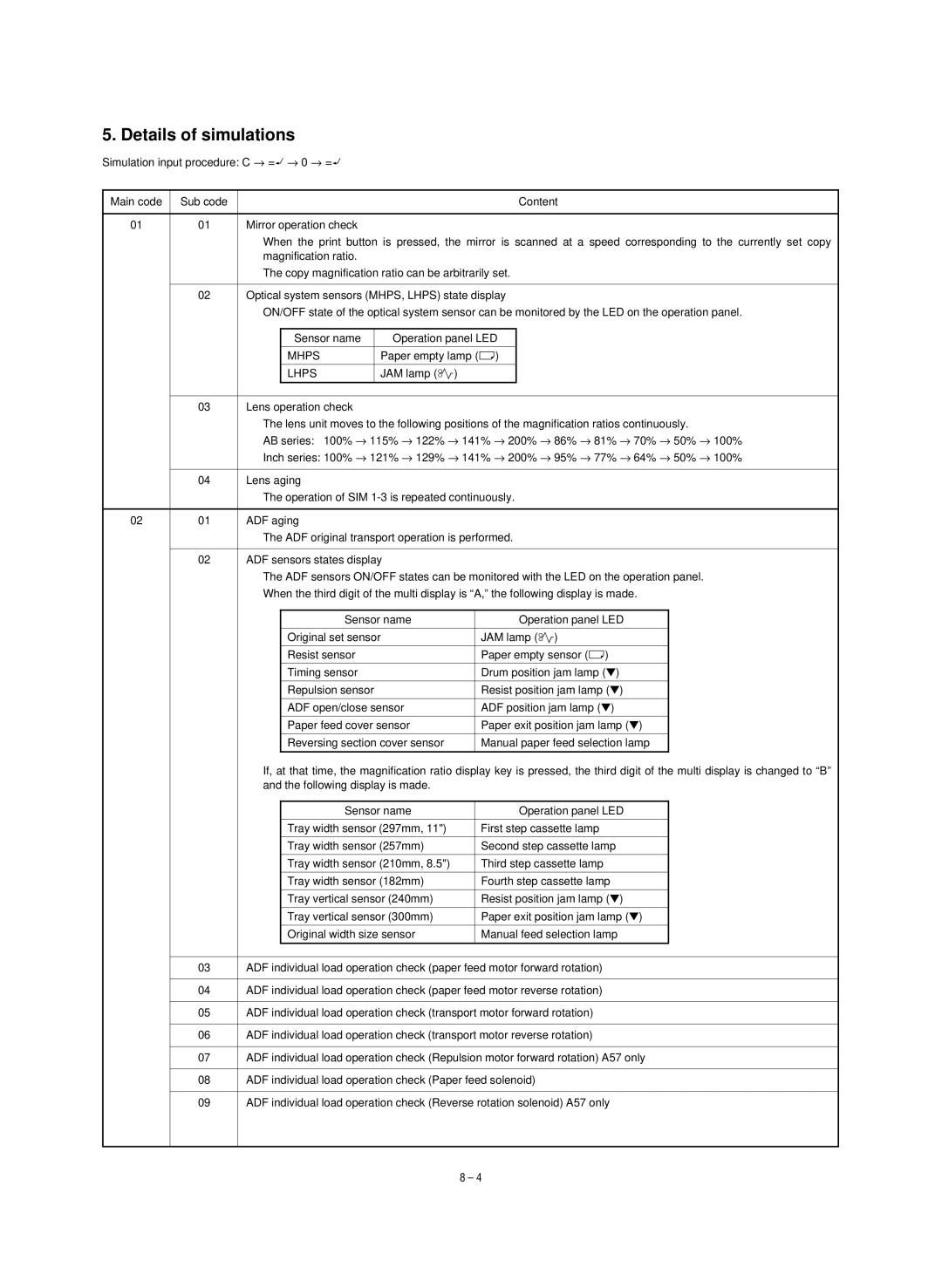

5. Details of simulations

Simulation input procedure: C → ë → 0 → ë

Main code | Sub code |

|

|

| Content |

|

|

|

|

|

|

01 | 01 | Mirror operation check |

|

| |

|

| When the print button is pressed, the mirror is scanned at a speed corresponding to the currently set copy | |||

|

| magnification ratio. |

|

| |

|

| The copy magnification ratio can be arbitrarily set. | |||

|

|

|

|

|

|

| 02 | Optical system sensors (MHPS, LHPS) state display | |||

|

| ON/OFF state of the optical system sensor can be monitored by the LED on the operation panel. | |||

|

|

|

|

|

|

|

|

| Sensor name | Operation panel LED |

|

|

|

|

|

|

|

|

|

| MHPS | Paper empty lamp (ç) |

|

|

|

|

|

|

|

|

|

| LHPS | JAM lamp (ê) |

|

|

|

|

|

|

|

|

|

|

|

| |

| 03 | Lens operation check |

|

| |

|

| The lens unit moves to the following positions of the magnification ratios continuously. | |||

|

| AB series: 100% → 115% → 122% → 141% → 200% → 86% → 81% → 70% → 50% → 100% | |||

|

| Inch series: 100% → 121% → 129% → 141% → 200% → 95% → 77% → 64% → 50% → 100% | |||

|

|

|

|

| |

| 04 | Lens aging |

|

| |

|

| The operation of SIM | |||

|

|

|

|

| |

02 | 01 | ADF aging |

|

| |

The ADF original transport operation is performed.

02 | ADF sensors states display |

The ADF sensors ON/OFF states can be monitored with the LED on the operation panel.

When the third digit of the multi display is “A,” the following display is made.

Sensor name | Operation panel LED |

|

|

Original set sensor | JAM lamp (ê) |

|

|

Resist sensor | Paper empty sensor (ç) |

|

|

Timing sensor | Drum position jam lamp (▼) |

|

|

Repulsion sensor | Resist position jam lamp (▼) |

|

|

ADF open/close sensor | ADF position jam lamp (▼) |

|

|

Paper feed cover sensor | Paper exit position jam lamp (▼) |

|

|

Reversing section cover sensor | Manual paper feed selection lamp |

|

|

If, at that time, the magnification ratio display key is pressed, the third digit of the multi display is changed to “B” and the following display is made.

|

| Sensor name | Operation panel LED |

|

|

|

|

|

|

|

| Tray width sensor (297mm, 11") | First step cassette lamp |

|

|

|

|

|

|

|

| Tray width sensor (257mm) | Second step cassette lamp |

|

|

|

|

|

|

|

| Tray width sensor (210mm, 8.5") | Third step cassette lamp |

|

|

|

|

|

|

|

| Tray width sensor (182mm) | Fourth step cassette lamp |

|

|

|

|

|

|

|

| Tray vertical sensor (240mm) | Resist position jam lamp (▼) |

|

|

|

|

|

|

|

| Tray vertical sensor (300mm) | Paper exit position jam lamp (▼) |

|

|

|

|

|

|

|

| Original width size sensor | Manual feed selection lamp |

|

|

|

|

|

|

|

|

| ||

03 | ADF individual load operation check (paper feed motor forward rotation) |

| ||

|

|

| ||

04 | ADF individual load operation check (paper feed motor reverse rotation) |

| ||

|

|

| ||

05 | ADF individual load operation check (transport motor forward rotation) |

| ||

|

|

| ||

06 | ADF individual load operation check (transport motor reverse rotation) |

| ||

|

|

| ||

07 | ADF individual load operation check (Repulsion motor forward rotation) A57 only |

| ||

|

|

| ||

08 | ADF individual load operation check (Paper feed solenoid) |

| ||

|

|

| ||

09 | ADF individual load operation check (Reverse rotation solenoid) A57 only |

| ||

8 – 4