[7] ADJUSTMENTS

1. Developing section

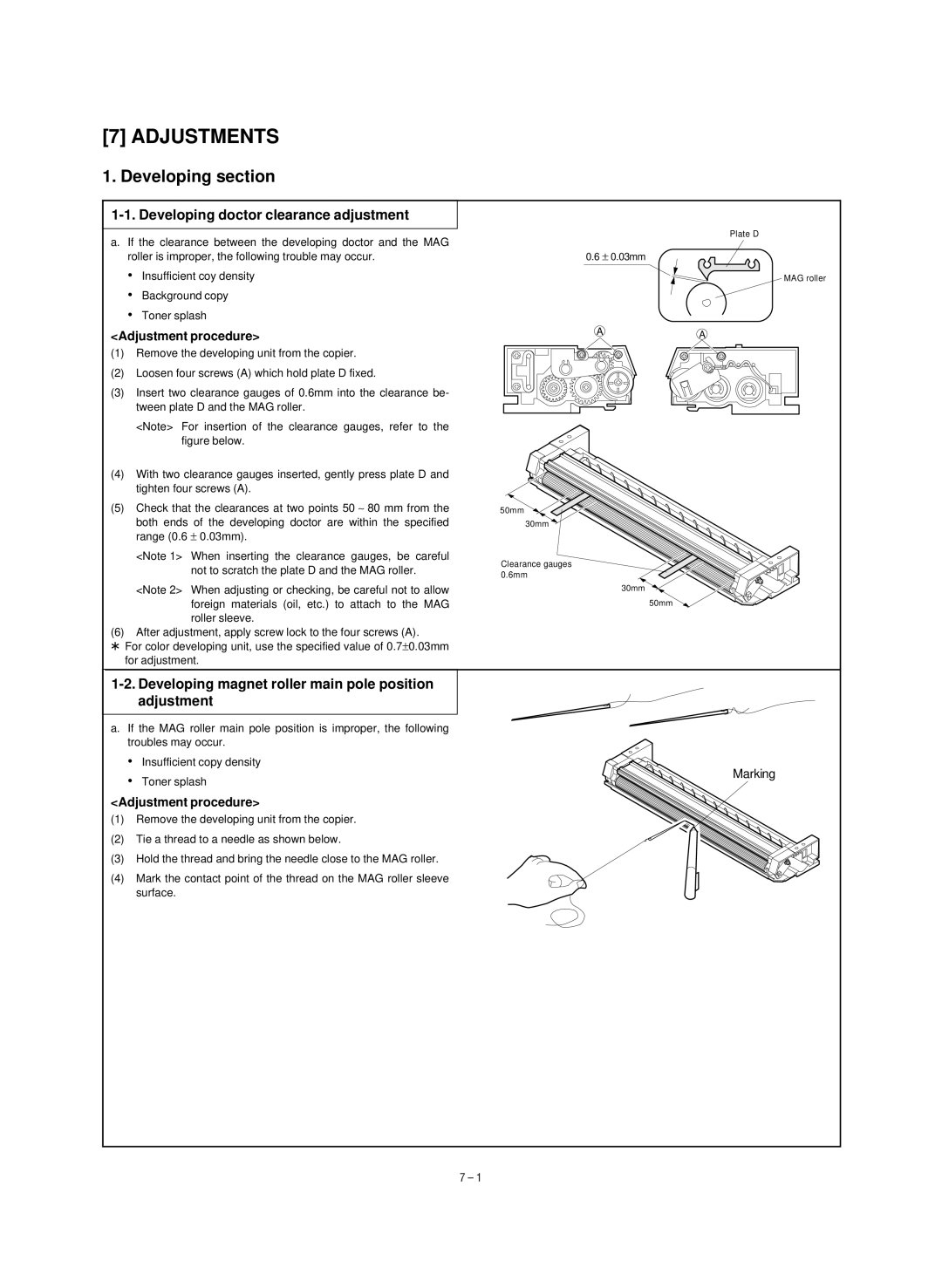

1-1. Developing doctor clearance adjustment

a.If the clearance between the developing doctor and the MAG roller is improper, the following trouble may occur.

•Insufficient coy density

•Background copy

•Toner splash

<Adjustment procedure>

(1)Remove the developing unit from the copier.

(2)Loosen four screws (A) which hold plate D fixed.

(3)Insert two clearance gauges of 0.6mm into the clearance be- tween plate D and the MAG roller.

<Note> For insertion of the clearance gauges, refer to the figure below.

(4)With two clearance gauges inserted, gently press plate D and tighten four screws (A).

(5)Check that the clearances at two points 50 ∼ 80 mm from the

both ends of the developing doctor are within the specified range (0.6 ± 0.03mm).

<Note 1> When inserting the clearance gauges, be careful not to scratch the plate D and the MAG roller.

<Note 2> When adjusting or checking, be careful not to allow foreign materials (oil, etc.) to attach to the MAG roller sleeve.

(6)After adjustment, apply screw lock to the four screws (A).

*For color developing unit, use the specified value of 0.7±0.03mm for adjustment.

Plate D

0.6 ± 0.03mm

MAG roller

AA

50mm ![]() 30mm

30mm ![]()

Clearance gauges 0.6mm

30mm

50mm

1-2. Developing magnet roller main pole position adjustment

a.If the MAG roller main pole position is improper, the following troubles may occur.

• Insufficient copy density

• Toner splash

Marking

<Adjustment procedure>

(1) Remove the developing unit from the copier.

(2) Tie a thread to a needle as shown below.

(3) Hold the thread and bring the needle close to the MAG roller.

(4) Mark the contact point of the thread on the MAG roller sleeve surface.

7 – 1