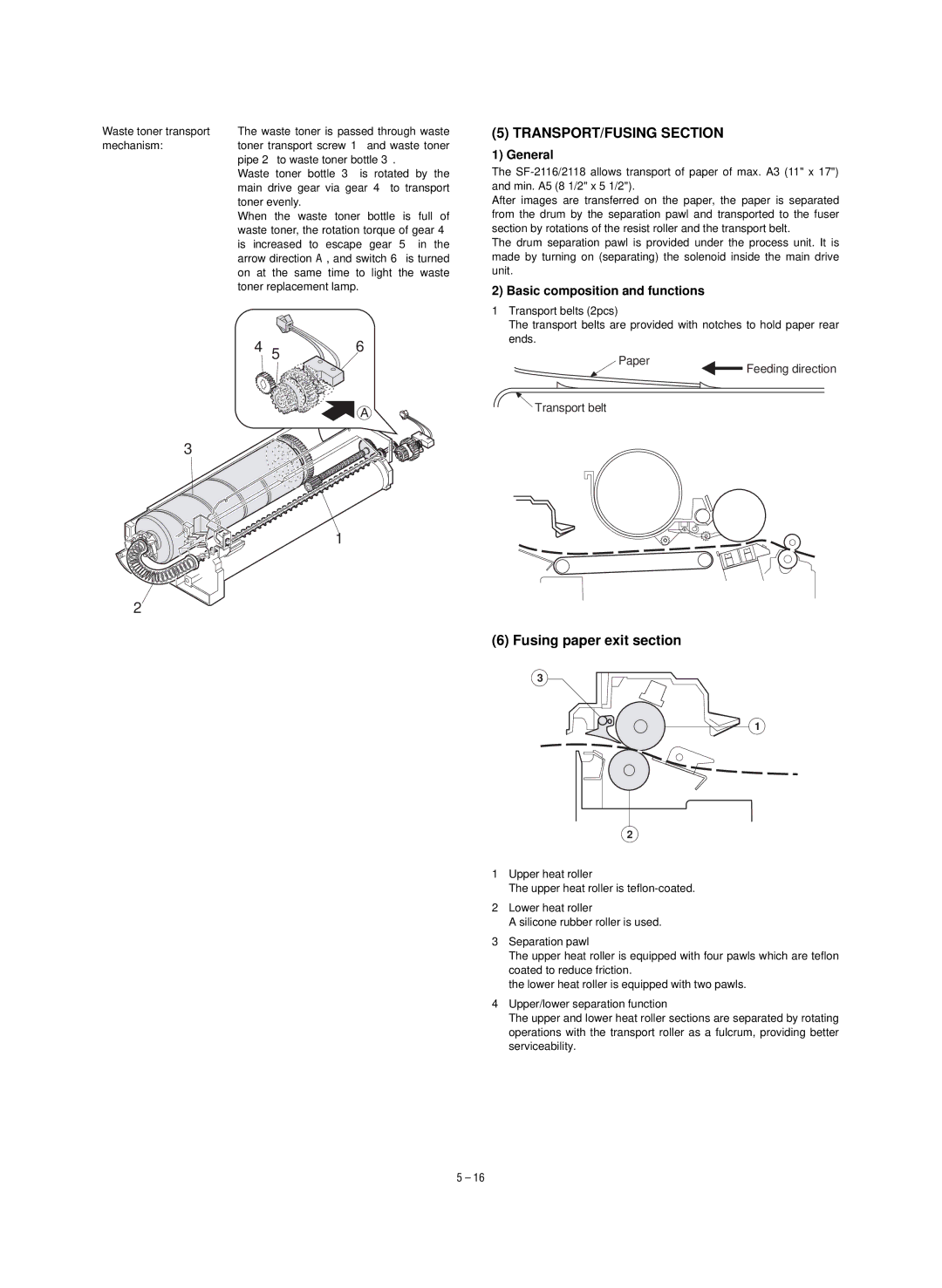

Waste toner transport | The waste toner is passed through waste |

mechanism: | toner transport screw 1 and waste toner |

| pipe 2 to waste toner bottle 3. |

| Waste toner bottle 3 is rotated by the |

| main drive gear via gear 4 to transport |

| toner evenly. |

| When the waste toner bottle is full of |

| waste toner, the rotation torque of gear 4 |

| is increased to escape gear 5 in the |

| arrow direction A, and switch 6 is turned |

| on at the same time to light the waste |

| toner replacement lamp. |

45 6

(5) TRANSPORT/FUSING SECTION

1) General

The

After images are transferred on the paper, the paper is separated from the drum by the separation pawl and transported to the fuser section by rotations of the resist roller and the transport belt.

The drum separation pawl is provided under the process unit. It is made by turning on (separating) the solenoid inside the main drive unit.

2) Basic composition and functions

1Transport belts (2pcs)

The transport belts are provided with notches to hold paper rear ends.

![]()

![]() A

A ![]() 3

3 ![]()

![]()

![]()

![]()

![]()

![]()

![]()

1

2

Paper

Transport belt

![]()

![]() Feeding direction

Feeding direction

(6) Fusing paper exit section

3

1

2

1Upper heat roller

The upper heat roller is

2Lower heat roller

A silicone rubber roller is used.

3Separation pawl

The upper heat roller is equipped with four pawls which are teflon coated to reduce friction.

the lower heat roller is equipped with two pawls.

4Upper/lower separation function

The upper and lower heat roller sections are separated by rotating operations with the transport roller as a fulcrum, providing better serviceability.

5 – 16