Hp LaserJet

Page

Service

Q2431-90912

Copyright Information

Table of contents

Printer operation

Removing and replacing parts

Troubleshooting

Index

Viii Table of contents Q2431-90912

List of figures

List of figures Q2431-90912

Q2431-90912 List of figures

Xii List of figures Q2431-90912

Q2431-90912 List of figures

Xiv List of figures Q2431-90912

List of tables

Xvi List of tables Q2431-90912

Q2431-90912 List of tables

Xviii List of tables Q2431-90912

Contents

Printer description

Printer description Q2431-90912

Printer configurations

Product configurations

Model and serial numbers

Sample model and serial number label

Printer specifications

Site requirements

Physical dimensions

Printer physical dimensions

Printer weights without print cartridge

Printer weights

Off

HP LaserJet 4300 series

General specifications Description HP LaserJet

Circuit requirements HP LaserJet 4200 series

Acoustic ratings

Paper specifications

Purchasing a large quantity

Supported sizes and weights of media

B5 ISO

Tray 1 Media specifications

Duplex accessory media specifications Size Dimensions Weight

Envelope feeder accessory Size Dimensions

Stacker and stapler/stacker do not support card stock

Supported types of media

Guidelines for using paper

Symptom Problem with paper Solution

Submenu on

Paper weight equivalence table

Paper weight equivalents

Labels

Overhead transparencies

Envelopes with double-side-seams

Envelopes

Envelope construction

Envelopes with adhesive strips or flaps

Envelope storage

Card stock and heavy paper

Envelope margins

Card stock construction

Types of print media to avoid

Laser safety

Safety information

Print cartridge and toner safety

Laser safety statement U.S

EMI statement Korea Vcci statement Japan

Varoitus

Laser statement Finland

Luokan 1 laserlaite Klass 1 Laser Apparat

Varning

Regulatory information

FCC regulations

Environmental product stewardship program

Material Safety Data Sheet For more information

Material restrictions

Returns Non-U.S. returns

Declarations of Conformity

Declaration of Conformity

Canadian DOC regulations

Service approach

Ordering information Related documentation and software

Service approach

Parts and supplies

Support

HP service agreements

HP-authorized resellers and support

HP PartnerCare

Worldwide service and support offices

Africa and Middle East

Recycling print cartridges

Print-cartridge information

Refilled print cartridges

Returns

Hewlett-Packard limited warranty statement

HP Product Duration of Warranty

Limited warranty for toner cartridge life

Service approach Q2431-90912

Printer operation

Control-panel lights

Using the control panel

Control-panel layout

Control-panel lights Light Indication

Using the printer Help system

Control-panel buttons

Control-panel buttons Button Function

Settings and defaults

Settings and defaults

Setting the control-panel display language

Setting or default Explanation

Printing and changing control-panel menus

Control-panel menus

Overview

To print a control-panel menu map

To change a control-panel setting

Retrieve job menu Values Explanation

Retrieve Job menu

Information menu

Information menu Explanation

Paper Handling menu

Paper-handling menu Values Explanation

Tray N Type ANY

Configure Device menu

Printing submenu

Printing submenu Values Explanation

PCL sub-submenu a submenu in the printing submenu

PCL submenu Values Explanation

Print Quality submenu

Print quality submenu Values Explanation

321 and Blurred print on page 321 . HP

Lines on page 321 and Blurred print on

Use the Resolution Enhancement technology REt

System Setup submenu

System setup submenu Values Explanation

Auto Continue to on

Stapler/stacker submenu

Stapler stacker submenu Values Explanation

Submenu

O submenu Values Explanation

Printer maintenance

Cleaning the printer and accessories

Location of the transfer roller do not touch

Cleaning the fuser

Cleaning the printer Component Cleaning method/notes

Running the cleaning page manually

To run the cleaning page manually

Running the cleaning page automatically

Cleaning spilled toner

To run the cleaning page automatically

Performing preventative maintenance

Resetting the maintenance-kit counter

Maintenance kit part numbers Part name Part number

Expected life of components

Maintaining the stapler unit

Removing and replacing the stapler unit

To remove and replace the stapler unit

Replacing the stapler unit 2

Loading staples

To load staples

Downloading a remote firmware update

Printer maintenance Q2431-90912

Theory of operation

Theory of operation Q2431-90912

Introduction

Basic operation of the printer

Printer operating sequence

Laser/scanner system overview

Control system overview

Pickup and feed system overview

Image formation system overview

General descriptions

DC controller PCA

Motor and fan control

Motor

Fan

Power supply

Fuser-control circuit

Fuser over-temperature protection

Fuser over-temperature protection circuit block diagram

High-voltage circuit block diagram

High-voltage circuit

Low-voltage circuit block diagram

Low-voltage circuit

Cartridge detection

Overcurrent/overvoltage protection

Toner detection

Cartridge memory

Laser/scanner assembly

Laser/scanner assembly

Laser control circuit block diagram

Laser/scanner control

Printer paper pickup and feed block diagram

Paper pickup system

Paper pickup/feed and fuser/delivery block diagram

Paper pickup and feed block

Tray 1 timing diagrams

Printing from tray

Tray 1 pickup

Q2431-90912 Theory of operation

Tray 2 timing diagrams

No cassette installed

Tray 2, 500-, 1,500-sheet feeder media size detection

Lifter-driver operation

Multiple feed prevention

Media skew prevention

Correcting skewed media pages

Fixing/delivery block

Printer pickup delay jam from tray

Printer jam detection

Printer pickup stationary jam

Printer delivery wrap jam when feeding regular media

Printer delivery wrap jam when feeding non-regular media

Printer delivery delay jam

Printer door open jam

Printer residual media jam

Printing from the 500-sheet feeder

Sheet feeder pickup and feeding

Sheet feeder pickup and feed diagram

500-sheet feeder I/O block diagram

Printing from the 1,500-sheet feeder

500-sheet feeder pickup and feed diagram

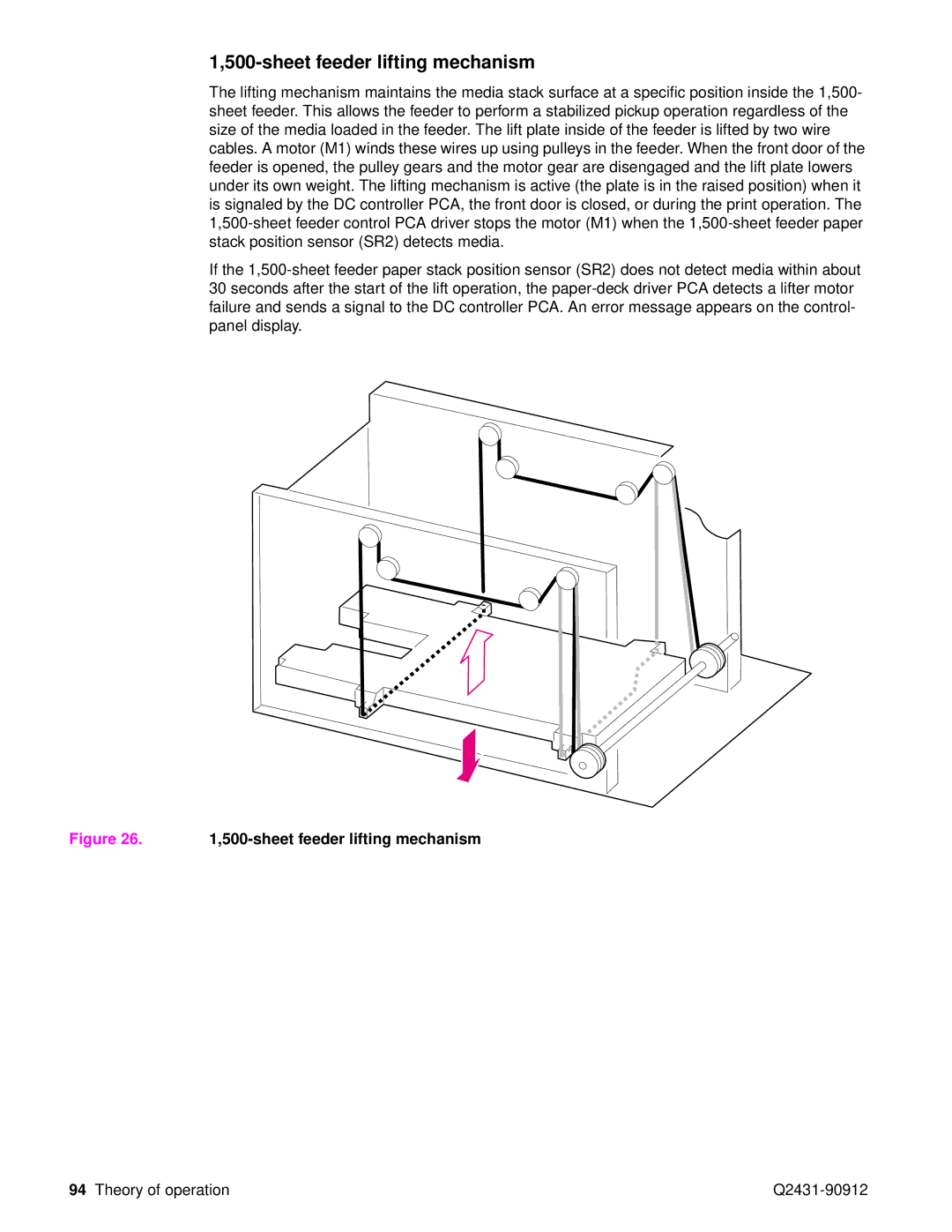

Sheet feeder lifting mechanism

500-sheet feeder lifting mechanism

Envelope feeder I/O block diagram

Envelope feeder

Envelope feeder pickup and feed diagram

Envelope feeder pickup and feeding

Envelope feeder pickup delay jam

Envelope feeder jam detection

Envelope feeder pickup stationary jam

Duplexer I/O block diagram

Duplexer

Duplexer pickup and reversing diagram

Reversing and duplexer pickup

Duplexer jam detection

Stacker and stapler/stacker

Stacker and stapler/stacker paper path

Power-on sequence for the stacker and stapler/stacker

Stacker driver PCA block diagram

Stacker

Stacker components Component Purpose

Switch

Stacker feed and delivery

Solenoid

Stacker feed stationary jam

Stacker jam detection

Stacker feed jam

Stacker residual media jam

Stapler/stacker driver PCA block diagram

Stapler/stacker

Stapler/stacker feed and delivery

Stapler/stacker components Component Purpose

Stapler/stacker motors, solenoids, and sensors block diagram

Staple mode feed and delivery

Staple mode feed and delivery diagram 1

Staple mode feed and delivery diagram 2

Staple mode feed and delivery diagram 4

Staple mode feed and delivery diagram 6

Stapler unit I/O block diagram

Stapler unit

Stapler unit operation

Stapler unit

Front view

Staple operation 2

Staple operation 3

Stack mode feed and delivery

Staple level detection

Stapler/stacker feed stationary jam

Stapler/stacker jam detection

Stapler/stacker feed jam

Stapler/stacker delivery jam

Image-formation system

Image formation block diagram

Electrostatic latent-image formation

Primary charging

Writing the image

Writing the image to the photosensitive drum

Developing the image

Developing the image

Transferring the image

Transferring the image

Fusing the image

Q2431-90912 Theory of operation

Print cartridge memory chip

Print cartridge memory chip

PowerSave

Resolution Enhancement technology

Formatter system

EconoMode

Input/output

Printer memory

PJL overview

Control panel

Removing and replacing parts

Page

After completing service

Removal and replacement strategy

Before performing service

Required tools

Phillips machine screw with captive star washer

Screws used in the printer

Screw measurement guide

Phillips screw with self-tapping threads

Access to the transfer assembly and to the registration

Parts-removal tree

Printer input tray, and cabinet wheel locks

Location of printer, input trays, and cabinet wheel locks

User-replaceable parts

Print cartridge

Print cartridge 1

Transfer roller

Open the control-panel door and tray

Tray 1 pickup roller

Tray 1 pickup roller 1

Tray 1 separation pad

Tray 1 separation pad

Tray 2 feed rollers

Tray 2 feed rollers 2

Tray 2 feed rollers 3

Accessory covers and the tray 2 extension door

Covers, tray 1, and the rear output bin

Accessory covers 3

Formatter cover

Top cover

Top cover 1

Top cover 3

Top cover 4

Top cover 5

Right-side cover

Right-side cover 1

Right-side cover 3

Left-side cover

Left-side cover 1

Tray

Tray 1 1

Slide the tray 1 door to the right and remove it

Tray 1 3

Tray 1 5

Slide the paper guide to the left to remove it

Tray 1 6

Rear output bin

Rear output bin 1

Control-panel display

Control-panel overlay

Control-panel assembly

Control-panel assembly 1

Control-panel assembly 2

Control-panel assembly 4

Internal components

Firmware Dimm

Firmware Dimm

Formatter assembly

Formatter assembly

Fuser

Output delivery assembly

Output delivery assembly rear view, formatter side 1

Output delivery assembly 2

Duplexing pendulum assembly

Duplexing pendulum assembly 1 o

Duplexing pendulum assembly 2

Tray 2 media-size sensor

Tray 2 media-size sensor 1

Main cooling fan left side

Main cooling fan 1

Main cooling fan 3

Cooling fan right side HP LaserJet 4300 series printer only

Cooling fan HP LaserJet 4300 series only 1

Cooling fan HP LaserJet 4300 series only 3

Cooling fan HP LaserJet 4300 series only 5

Laser/scanner 1

Laser/scanner 3

Laser/scanner 4

Print-cartridge motor HP LaserJet 4300 series printer only

Print-cartridge motor HP LaserJet 4300 series only 1

Print-cartridge motor HP Laserjet 4300 series only 1

Main motor

Main motor 1

Remove it

Main motor 3

Tray 2 lifter-drive assembly

Tray 2 lifter-drive assembly 1

Tray 2 lifter-drive assembly 2

DC controller PCA 1

DC controller PCA 2

Paper-pickup assembly

Paper-pickup assembly 1

Paper-pickup assembly 3

Paper-pickup assembly 5

Main drive assembly

Main drive assembly 1

Main drive assembly 2

Power supply right side 1

Power supply 2

Power supply tray 2 cavity 4

Paper-feed belt assembly

Paper-feed belt assembly 1

Tray 1 paper-pickup assembly

Tray 1 pickup assembly 1

Tray 1 pickup assembly 2

Tray 1 pickup assembly 4

Paper feed assembly

Paper feed assembly 1

Paper-feed assembly 2

Reinstall note Hint

Registration assembly

Registration assembly 1

Registration assembly 3

Transfer assembly

Transfer assembly 1

Transfer assembly left rear view 2

Transfer assembly 3

Transfer assembly 5

Sheet feed rollers

Accessories

Sheet feeder assembly

Sheet feeder right-side cover

Sheet feeder right-side cover 2

Sheet feeder right-side cover 4

Sheet feeder control PCA

Sheet feeder control PCA

Sheet feeder media-size sensor

Sheet feeder media-size sensor 1

Sheet feeder lifter-drive assembly

Sheet feeder lifter-drive assembly 1

Sheet feeder paper-pickup drive assembly

Sheet feeder paper-pickup drive assembly 1

Sheet feeder paper-pickup drive assembly 3

Sheet feeder paper-pickup drive assembly 5

Sheet feeder paper-pickup drive assembly 7

Sheet feeder feed rollers

Sheet feeder separation roller

Sheet feeder door

500-sheet feeder door 1

Sheet feeder door 3

Sheet feeder rear cover

500-sheet feeder rear cover 1

500-sheet feeder right-side cover 1

500-sheet feeder right-side cover 3

500-sheet feeder control PCA 1

500-sheet feeder media-size sensor

500-sheet feeder lifter-drive assembly 1

500-sheet feeder lifter-drive assembly 2

500-sheet feeder lifter-drive assembly 4

500-sheet feeder paper-pickup drive assembly

Removing and replacing parts Q2431-90912

Troubleshooting

Troubleshooting Q2431-90912

Q2431-90912 Troubleshooting

Introduction

Troubleshooting process

Initial troubleshooting checklist

Initial troubleshooting checklist Miscellaneous

Troubleshooting flowchart

Troubleshooting flowchart 1

Troubleshooting flowchart 2

Power-on checks

Overview

Power-on defect or blank display Problem Action

Power-on defect or blank display

Troubleshooting tools

Information pages

Menu map

Sample menu map

Configuration

Configuration

Supplies status

Supplies status

Gaining access to the embedded Web server

Embedded Web server

Settings tab

Information tab

Networking tab

Printer Status and Alerts software

Other links

To select status messages

To view status messages and information

Resets submenu Values Explanation

Using control-panel menus

Resets submenu

Information see System Setup submenu on

Diagnostics menu

Diagnostics menu Values Explanation

Service menu service PIN codes

For the HP LaserJet 4300 product

Service ID

Restoring the Service ID

Converting the Service ID to an actual date

To perform a cold reset

Printer resets and power-on modes

Cold reset

Nvram initialization

To initialize the hard disk

Power-on bypass

Hard-disk initialization

Skip disk load

Self test

Test pages

Engine test

Formatter test

Communications checks

Interface troubleshooting

EIO troubleshooting

Computer direct connect parallel test

Jetdirect

Jetdirect

Critical-error messages

Display-message troubleshooting

Error messages

Status messages

Alphabetical printer messages

Alphabetical printer messages Message Description Action

See DC controller PCA on

Top cover is open or the top Press the H ELP Button for

Dimm on

Firmware Dimm on

See Power supply on

See Configuration page on

Switches and sensors on

336 , 500 -sheet feeder

Configuration page on

Fuser on

See Fuser on

Sheet feeder media

Stacker or stapler/stacker LED Blinks in amber

On page 241 to see if

Size detection on

Printer has detected that an If the print cartridge appears

Stacker or stapler/stacker

LED blinks in amber

Stacker or stapler/stacker LED

See Firmware Dimm on

Power supply on

Sheet feeder

Control PCA on

See 1,500-sheet feeder

Stapler/stacker LED is

Error applies to the stapler/stacker

Amber this error applies to

Only

On page 340, or

Tray was installed with Use the control panel to

Configuration of tray XX. The tray Press the S Elect

Select the Paper Handling

Numerical printer messages

Numerical printer messages Message Description Action

Cartridge on

See Paper-path

See Printer switches

Install the paper-feed

Assembly sensor flag on

Sheet feeder switches

Paper-feed assembly sensor

Printer switches

Correctly install

Location of printer switches

See Location of printer

336 and Fuser on

Removing and replacing

JAM in Output Device

Functions to OFF

Tray 2 feed rollers on

Description

Drivers and Software . Check

Replace the Dimm or

Scanner assembly on

ZZ Error Number

Formatter assembly on

Cartridge fan error F2

Main fan error F1

DC controller

Air temperature sensor

Power supply

Sensor. See Main cooling

59.00, 59.10, 59.20 Motor

Or 59.4 EP Motor failure

LJ 4300 only

Print-cartridge motor

Assembly. See Tray 2 lifter

Feeder lifter-drive assembly

On page 209 or 1,500-sheet

60.4

Is off

Amber

Settings and defaults on

Is continuously illuminated

Stapler unit on

Initialize Nvram on

Initialize the hard disk on

Critical hardware error has Turn the printer off and then

Paper-path troubleshooting

Jam locations

Paper-jam recovery

To disable the paper-jam recovery

Common causes of paper jams Cause Solution

Avoiding paper jams

Basic troubleshooting for persistent jams

Persistent jams

Data collection

General paper-path troubleshooting

Paper-path checklist

Paper-path test

To perform a paper- test

Tray 1 paper-pickup assembly on

Causes of tray 1 jams Solution

Causes of tray 2 jams Solution

Drive assembly on page 179 and/or Printer

Causes of tray 3 and or tray 4 jams Solution

Jams in tray 3 and/or tray

Drive assembly on

Causes of paper-path jams Solution

Causes of duplex path jams Solution

Jams in the paper path

Cause Solution

Media transport problems

Causes for multiple pages feeding Solution

Multiple pages feed

Causes for skewed paper Solution

Registration assembly on

Paper is skewed

Image-formation troubleshooting

Print quality problems associated with media

Print quality problems associated with the environment

Print quality problems associated with jams

Overhead transparency defects

Image defects

Does the problem repeat on the page?

HP paper specification

Image quality

Check the print cartridge

EconoMode

Half self-test functional check

Drum rotation functional check

Image defect tables

Print quality image defects

Print quality image defects

Light print partial Possible cause Recommended actions

Light print entire Possible cause Recommended action

Specks or dots Possible cause Recommended action

Dots in the paper path direction

Cartridge Wrong toner density setting

Might cause problems if the paper is

Have this problem because they are not

Wrong fuser setting for media type

Horizontal lines opposite the paper path direction

Grey background Possible cause Recommended actions

Repeating defects and repeating images

Distorted images

Skew Possible cause Recommended actions

Curl or wave Possible cause Recommended actions

Creases Possible cause Recommended actions

White lines opposite the paper path

Scattered lines Possible cause Recommended actions

Line detail setting is turned off

White spots on black Possible cause Recommended actions

Blurred print Possible cause Recommended actions

Replace the laser/scanner assembly. See Laser/scanner

Black

Blank or white Possible cause Recommended actions

Dark print

Repetitive defects troubleshooting

Repetitive defect ruler

Troubleshooting the stacker and the stapler/stacker

Initial checks

Stacker paper path test

Jam errors

Stacker and stapler/stacker paper path

Delivery area Printer connection area

Stapler/stacker paper path test

Damaged

Q2431-90912 Troubleshooting

Paper transport errors

Malfunction errors

Paper transport error troubleshooting

Component errors

Printer component locations

Main printer parts

Location of main printer parts 2

Location of main printer parts 3

Location of main printer parts 4

Printer switches and sensors

Location of printer switches and sensors

Printer motors and fans

Location of printer motors and fans

Printer PCAs

Location of printer PCAs

Accessory component locations

Sheet feeder main parts

Sheet feeder switches, sensors, solenoids, and PCAs

Location of 1,500-sheet paper feeder main parts 1

Location of 1,500-sheet paper feeder main parts 2

Sheet feeder switches, sensors, solenoids, and PCAs

Stapler/stacker stapler assembly

Location of the stapler/stacker stapler unit

Stacker and stapler/stacker switches and sensors

Stacker and stapler/stacker motors and solenoids

Stacker and stapler/stacker PCAs

Location of the stacker and stapler/stacker PCAs

Printer and accessory wiring diagrams

HP LaserJet 4200 wiring diagram

HP LaserJet 4300 wiring diagram

Sheet feeder wiring diagram

500-sheet feeder wiring diagram

Duplex accessory wiring diagram

Envelope feeder accessory wiring diagram

Stacker accessory wiring diagram

Stapler/stacker accessory wiring diagram

DC controller block diagram

DC controller top

General timing diagrams

HP LaserJet 4200 general timing diagram

HP LaserJet 4300 general timing diagram

Stapler/stacker timing diagram

Troubleshooting Q2431-90912

Parts and diagrams

Ordering parts, supplies, and getting support

Ordering information

HP-authorized resellers and support

Accessories and supplies

Memory, fonts, and mass storage Part number Exchange number

Cables and interfaces Part number Exchange number

Printer maintenance kit

Part number Exchange number

How to use the parts lists and diagrams

Documentation Part number Description or use

Parts diagrams and lists

External covers and panels

External covers and panels Part number Description Reference

Main assemblies 1

Main assemblies 1 Part number Description Reference

Main assemblies 2

Main assemblies 2 Part number Description Reference

Main assemblies 3

Main assemblies 3 Part number Description Reference

Right-side assemblies Part number Description Reference

110-127v 220-240v

Main drive assembly Part number Description Reference

Paper-pickup assembly Part number Description Reference

RM1-0002-000CN Duplexing pendulum assembly

RM1-0033-000CN Lifter-drive assembly, tray

Paper pickup assembly Part number Description Reference

Paper-feed assembly Part number Description Reference

Registration assembly Part number Description Reference

Tray 1 assembly Part number Description Reference

Output delivery assembly Part number Description Reference

Transfer assembly

Transfer assembly Part number Description Reference

Fuser Parts and diagrams Q2431-90912

Fuser Part number Description Reference

Parts and diagrams Q2431-90912

Q2431-90912 Parts and diagrams

Sheet feeder main assemblies 2

Q2431-90912 Parts and diagrams

RM1-0056-000CN Paper-pickup assembly 500-sheet feeder

RM1-0208-000CN Lifter-driver assembly 500-sheet feeder

Sheet tray

Sheet tray Part number Description Reference

Q2431-90912 Parts and diagrams

500-sheet feeder main assemblies

Paper size sensing assembly outside, 1,500-sheet feeder

Parts and diagrams Q2431-90912

RM1-0287-000CN Lifter-drive assembly, 1,500-sheet feeder

Parts and diagrams Q2431-90912

Q2431-90912 Parts and diagrams

Parts and diagrams Q2431-90912

Alphabetical parts list

Alphabetical pars list Part number Description Reference

Alphabetical pars list Part number Description Reference

Paper size sensing assembly outside, 1,500-sheet feeder

Alphabetical pars list Part number Description Reference

Numerical parts list

Numerical pars list Part number Description Reference

Numerical pars list Part number Description Reference

Numerical pars list Part number Description Reference

Paper size sensing assembly outside, 1,500-sheet feeder

Index

Index Q2431-90912

Cassettes. See trays CD-ROM, software

Index Q2431-90912

EIO

Index Q2431-90912

See also support troubleshooting Help button 36

LED PCA

Q2431-90912 Index

Index Q2431-90912

Q2431-90912 Index

See also bins

Q2431-90912 Index

Index Q2431-90912

LED PCA

TCP/IP

See also trays

See also messages troubleshooting problem areas

Page

Q2431-90912