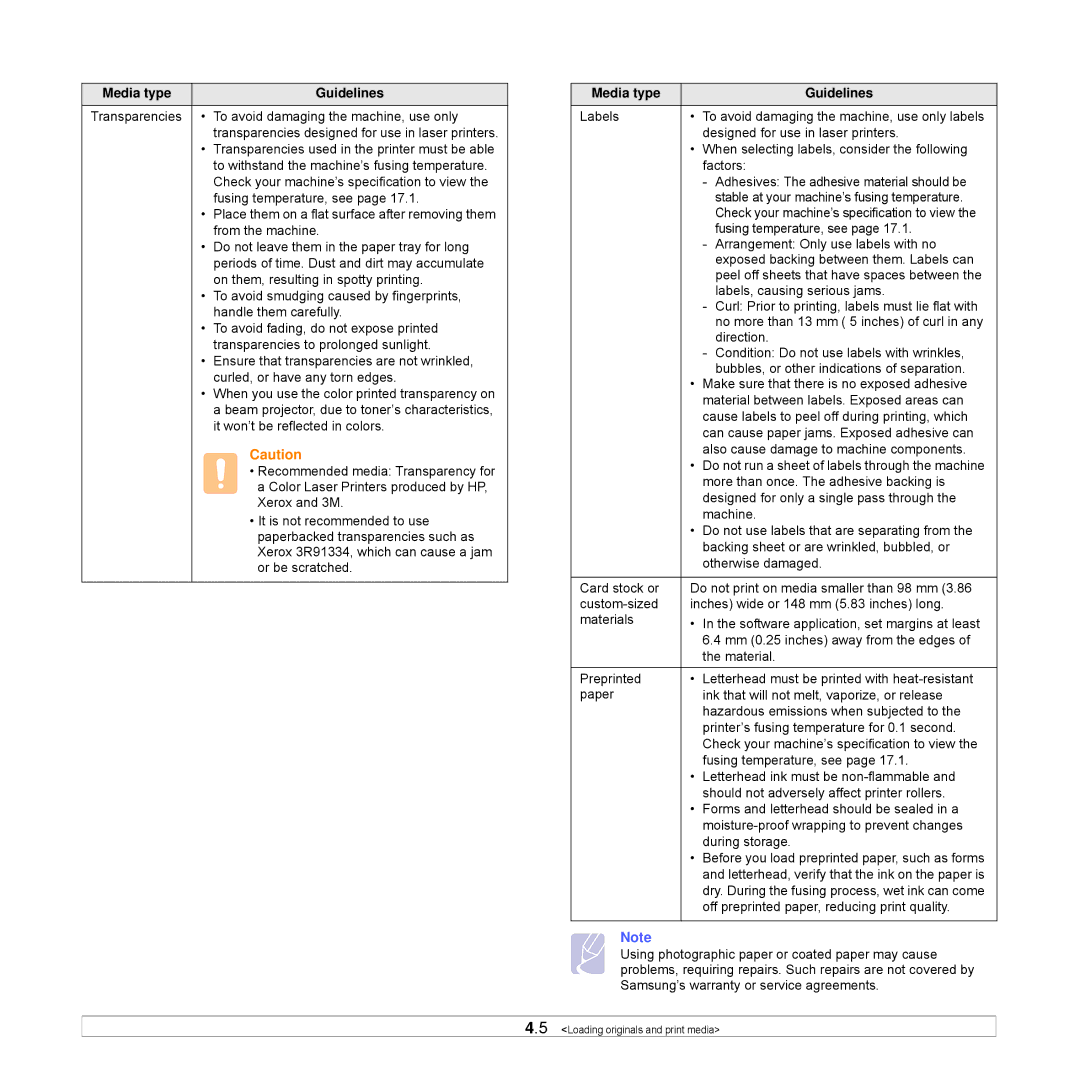

Media type | Guidelines |

Transparencies • | To avoid damaging the machine, use only |

| transparencies designed for use in laser printers. |

• | Transparencies used in the printer must be able |

| to withstand the machine’s fusing temperature. |

| Check your machine’s specification to view the |

| fusing temperature, see page 17.1. |

• Place them on a flat surface after removing them | |

| from the machine. |

• | Do not leave them in the paper tray for long |

| periods of time. Dust and dirt may accumulate |

| on them, resulting in spotty printing. |

• | To avoid smudging caused by fingerprints, |

| handle them carefully. |

• | To avoid fading, do not expose printed |

| transparencies to prolonged sunlight. |

• | Ensure that transparencies are not wrinkled, |

| curled, or have any torn edges. |

• | When you use the color printed transparency on |

| a beam projector, due to toner’s characteristics, |

| it won’t be reflected in colors. |

Caution

• Recommended media: Transparency for a Color Laser Printers produced by HP, Xerox and 3M.

• It is not recommended to use paperbacked transparencies such as Xerox 3R91334, which can cause a jam or be scratched.

Media type |

|

| Guidelines |

Labels | • | To avoid damaging the machine, use only labels | |

|

| designed for use in laser printers. | |

| • | When selecting labels, consider the following | |

|

| factors: | |

|

| - | Adhesives: The adhesive material should be |

|

|

| stable at your machine’s fusing temperature. |

|

|

| Check your machine’s specification to view the |

|

|

| fusing temperature, see page 17.1. |

|

| - | Arrangement: Only use labels with no |

|

|

| exposed backing between them. Labels can |

|

|

| peel off sheets that have spaces between the |

|

|

| labels, causing serious jams. |

|

| - | Curl: Prior to printing, labels must lie flat with |

|

|

| no more than 13 mm ( 5 inches) of curl in any |

|

|

| direction. |

|

| - | Condition: Do not use labels with wrinkles, |

|

|

| bubbles, or other indications of separation. |

| • | Make sure that there is no exposed adhesive | |

|

| material between labels. Exposed areas can | |

|

| cause labels to peel off during printing, which | |

|

| can cause paper jams. Exposed adhesive can | |

|

| also cause damage to machine components. | |

| • Do not run a sheet of labels through the machine | ||

|

| more than once. The adhesive backing is | |

|

| designed for only a single pass through the | |

|

| machine. | |

| • | Do not use labels that are separating from the | |

|

| backing sheet or are wrinkled, bubbled, or | |

|

| otherwise damaged. | |

|

| ||

Card stock or | Do not print on media smaller than 98 mm (3.86 | ||

inches) wide or 148 mm (5.83 inches) long. | |||

materials | • | In the software application, set margins at least | |

|

| 6.4 mm (0.25 inches) away from the edges of | |

|

| the material. | |

Preprinted | • | Letterhead must be printed with | |

paper |

| ink that will not melt, vaporize, or release | |

|

| hazardous emissions when subjected to the | |

|

| printer’s fusing temperature for 0.1 second. | |

|

| Check your machine’s specification to view the | |

|

| fusing temperature, see page 17.1. | |

| • | Letterhead ink must be | |

|

| should not adversely affect printer rollers. | |

| • | Forms and letterhead should be sealed in a | |

|

| ||

|

| during storage. | |

| • | Before you load preprinted paper, such as forms | |

|

| and letterhead, verify that the ink on the paper is | |

|

| dry. During the fusing process, wet ink can come | |

|

| off preprinted paper, reducing print quality. | |

|

|

|

|

Note

Using photographic paper or coated paper may cause problems, requiring repairs. Such repairs are not covered by Samsung’s warranty or service agreements.

4.5 <Loading originals and print media>