51-52-25-55D

UDC Universal Digital Controller Product Manual

Revision D April

Honeywell West Spring Street Freeport, Illinois

References

Abstract

Contacts

World Wide Web

Symbol Definition

Symbol Definitions

Table of Contents

147

Configuration Prompt Definitions

205

Operation

233

219

243

271

DC330X-EE-XXX-X2, DC330X-AA-XXX-X2

Figures

Tables

154

246

Xii UDC 3300 Controller Product Manual

Configurable parameters

Pharmaceuticals, and testing and environmental work

Introduction

Offered in a 1/4 DIN size controller

UDC 3300 Controller Product Manual

Operator Interface

Operator Interface Displays and Indicators

Loop 1/2

Function of keys

SPn

Key

ToBEGIN

OTI

UDC 3300 Controller Product Manual

Introduction What’s in this section?

Overview

Topic See

Stray Rejection Common Mode

Specifications

Normal Mode

Design

Electromechanical Relays One or Two

Current Output Isolated

Solid State Relays One or Two

Open Collector Outputs One or Two

Dmcs

Power Consumption Power Inrush Current Weight

RS422/485 Ascii RS422/485 Modbus

RTU

Mechanical Shock

Environmental and Operating Conditions

Voltage Vdc Voltage Vac 90 to 240 Vac 24 Vac Frequency Hz

Model number

Model Number Interpretation

Dimensions

Physical considerations Overall dimensions

Mounting

Mounting procedure

Refer to -3 and follow the procedure in -2 to mount

Step Procedure for Mounting the Controller Action

Controller

Control/alarm circuit wiring

Wiring

Electrical Noise Precautions

Electrical considerations

Permissible wire bundling

Shows which wire functions should be bundled together

Permissible Wiring Bundling Bundle No Wire Functions

Identify your wiring requirements

Wiring the controller

Using the information contained in the model number, select

Wiring Requirements

Controller accordingly

Wiring Diagrams

Controller 4 mm2

Line voltage wiring

Due to the voltage drop caused by the in-rush current

Thermocouple MV or Volts

Input #1/Input #2 connections

Except 0-10 Volts

Volts Milliamps

High Level Analog Input Connections See Below

Two Hlai replace second Llai connections

5V Connections MA Connections

22 + 23 +

Alarm Relay #1 Load

L2/N Power

Time proportional output

Electromechanical Relay Output-Model DC330X-EE-XXX

Relay Load Power

Alarm Relay #2 Load

Alarm Relay #1 Load AC Load

AC Load

10 10-amp Solid State Relay Output-Model DC330X-SS-XX

Time Proportional Simplex

Current output/ universal output connections

Output or Alarm Load

Controller Load L2/N

Ohms

Output Type Current

16 +

Relay #1

Calibration

Position proportional output connections

Mechanically linked To motor

Connect shield to ground At one end only

Auxiliary Load

Auxiliary output connections

1000 Ω

Digital inputs connections

Master L2/N

Full duplex wiring

TX-/RX

Do not mix half

120 Ohm

Master

Resistor

Configure

+16 26 + 250 ohm Resistor

Zero VAL = Span VAL =

Diode here to reduce

Voltage at transmitter

Lists the Alarm Relay contact information

Control and Alarm Relay Contact Information

Lists the Control Relay contact information

Introduction

Continuous background tests that are being performed

Topic

Prompts

Diagram prompt hierarchy

Configuration Prompts

TOT Rate * x = 0 to

Input

Configuration record sheet

How To Get Started

Parameter explanations or definitions

Configuration Tips

Configuration Tips

Introduction Procedure

Configuration Procedure

Configuration Procedure Step Operation

Press

Step Operation

SET UP Lower Display

Factory Setting

Loop 1 Tuning Parameters Set Up Group

Function prompts

Function Prompt

Disabl Enable

Selections or Range of Setting

Function Name

Tuning Loop 2 Group Function

Loop 2 Tuning Parameters Set Up Group Cascade or Two Loops

Function Selections or Name Range of Setting

Lists all the function prompts in the SP Ramp Set Up group

SP Ramp, SP Rate, or SP Programming Set Up Group

Setpoint rate

Function prompts Function Prompt

SEG1RATE SEG2 SP SEG2TIME

Recycles Soak DEV Prog END State Keyreset Hotstart

SEG3RATE SEG4 SP SEG4TIME

SEG5RATE SEG6 SP SEG6TIME

Accutune Set Up Group

Factory Refer Setting

Lists the function prompts in the Accutune Set Up group

Accutune Group Function Prompts

Function Selections or

Introduction Function prompts

Algorithm Data Set Up Group

Algorithm Group Function Prompts

None

INP ALG1

Math K Calc HI Calc LO ALG1 INA ALG1 INB ALG1 INC

PCO SEL PCT CO ATM Pres ALG1BIAS INP ALG2

ALG2 INA

Factory Setting Refer

ALG2 INB

ALG2 INC

Totalize Xxxxxxx TOT Scal TOT SEC Rset ? TOT Rate

Output Algorithm Group Function Prompts

Output Algorithm Parameters Set Up Group

OUT ALG

OUT2 ALG Rlystate

Input 1 Group Function Prompts Selections or

Input 1 Parameters Set Up Group

IN1 Type XMITTER1

Analytic IN1 HI IN1 LO Ratio

Filter

Bias IN1

BURNOUT1

None Down Nofs

Input 2 Parameters Set Up Group

Input 3 Group Function Selections or Range of Setting

Input 3 Parameters Set Up Group

Process

Loop 1 Control Parameters Set Up Group

12 Control Group Function Prompts Selections or

PCT/M UP PCT/M DN

OUT Rate

Dropoff Deadband OUT Hyst Failmode Failsafe Swfail

MAN OUT Auto OUT

13 Control 2 Group Function Prompts

Loop 2 Control Parameters Set Up Group

INP

OUTHiLIM OUTLoLIM HiLIM I LoLIM

OUT Rate PCT/M UP PCT/M DN

Dropoff Deadband Failmode Failsafe

Prompts will not appear

Options Set Up Group

Options Group Function Prompts

AUX OUT CUR OUT2

+DISAT

DIG1 COM DIG2 COM

+RUN

None Disabl

15 Communications Group Function Prompts

Communications Set Up Group

Shedenab Shedtime Parity Baud

Duplex

Last To LSP Percnt Disabl

Fsafe To MAN To LSP To CSP Percnt ENG

A1S1 VAL A1S2 VAL A2S1 VAL A2S2 VAL

Alarms Set Up Group

A1S1 H L

A1S1TYPE A1S2TYPE A2S1TYPE A2S2TYPE

A1S1 EV

A1S2 H L

A2S1 EV

A2S1 H L

A2S2 H L

A2S2 EV AL Hyst ALM OUT1 Block

Display Group Function Prompts

Display Parameters Set Up Group

Decimal

DECIMAL2

Calibration data

Calibration Group

Others, to keep track of maintenance needs

Maintenance Set Up Group

Maintenance Group Function Prompts

Elapsed Time Timer

Status Group

Counter Number of Counts Password Reset Type

Status test data

Disabl None

Keep a record

Configuration Record Sheet

Group Prompt

Value or Selection Factory Setting

Function Value or Prompt Selection

Expanded Model DC330E-XX-XXX

Value or Selection

Control CONTROL2 Options

UDC 3300 Process Controller Product Manual

Configuration Prompt Definitions

Tuning Group Prompt Definitions Lower Display

Introduction Set this group last Tuning group prompts

Upper Display Range of Setting Or Selection

Parameter Definition

Rset MIN Rset RPM MAN Rset PROPBD2 Gain

Lower Display Prompt

Configure Until ALL Configuration is Complete

None Calib + Conf + View MAX Disabl Enable

Security Lockout Auto MAN SP SEL RUN Hold

Gain PV band over which each Value Gain applies

Introduction Tuning 2 group prompts

Loop 2 Tuning Parameters Set Up Group

Loop 2 Tuning Group Prompt Lower Display

Introduction SP Ramp/Rate/ Programming group prompts

Setpoint Ramp/Rate/Programming Set Up Group

Setpoint Ramp/Rate Group Definitions Lower Display Prompt

EU/HR UP EU/HR DN EU/HRUP2

Final SP SP Rate

EU/HRDN2 SP Prog

Or Selection

Accutune Group Definitions Lower Display Prompt

Introduction Accutune group prompts

Setpoint Tuning Plus PV Adaptive TUNE- Same

Demand Tuning Plus PV Adaptive TUNE- Same

Disabl Tune TUN+PV SP+PV

Accutune for Loop

Criteria CRITERA2

KPG SP CHAN2

Read Only

AT Error AT ERR

Runing None Outlim Idfail Abort LOW PV

Algorithm Group Definitions Lower Display Prompt

Introduction Algorithm group prompts

PID a PID B

Pidloops

ALG

3PSTEP Loop 2LOOPS Cascad

PID a PID B PD+MR Disabl HI SEL LO SEL

KEY ALARM2 TI REM Time

Timer Period Start Disp

None AVG

Summer with Ratio and BIAS- The following

Relhum

Input High Select with Ratio and BIAS- This

Multiplier with Square ROOT- The following

Math K Calc HI Calc LO

Carb B Carb C Carb D FCC DEW PT Oxygen

INP LP1OUT LP2OUT AL1 AL2 None Disabl Online

Disabled

For Example

FWR2

Lower Display Upper Display Prompt Range of Setting

FFWDM2

Mult

PCT H2 ALG2BIAS

Where

Flow Sfcm

Summary of Flow Values At Values Conditions

X0 Input Value X Axis

8SEG CH1

X1 Input Value X Axis

X2 Input Value X Axis

X0 VALU2

Segment Characterizer #2- a second eight

Example of Eight Segment Characterizer

Unlock Lock YES

Totalize Xxxxxxx TOT Scal TOT SEC Rset ?

Read only

Second Minute Hour DAY ML/DAY

Output Algorithm Group Definitions Lower Display Prompt

Introduction Output algorithm group prompts

Time Currnt Positn Time D

Other prompts affected 4-20 RNG

CUR D CUR TI TI CUR

OUT2 ALG Rlystate RLY Type

Bias, filter, burnout, and emissivity

Upper Display Parameter Range of Setting Definition

Input 1 group prompts Lower Display Prompt

Input 1 Group Definitions

ORP

Xmitter Analytic

Conductivity

Resistivity

IN1 LO Ratio Bias IN1 Filter Burnout

EMISSIV1

Introduction Input 2 group prompts Lower Display Prompt

Slidewire

Input 2 Group Definitions

IN2 Type

Input 3 Group Definitions

Introduction Input 3 group prompts Lower Display Prompt

IN3 Type

XMITTER2 IN3 HI IN3 LO Ratio Bias IN3 Filter

PV Source PID Sets

Introduction Control group prompts Lower Display Prompt

Input

Input Algorithm

2PV SW 2SP SW Gain S

PID Sets SW Value LSP’S

Three

Setpoint Select

Manual LSP RSP

RSP SRC Autobias SP Track

SP HiLIM

For Three Position Step Control Only

Control Output DIRECTION- Select direct or reverse acting

OUT Rate PCT/M UP

OUTLoLIM Hi LIM Lo LIM

Failsafe Mode

Dropoff

OUT Hyst Failmode Failsafe Swfail

PB PCT Gain

PBorGAIN

RPM MIN

11 Control 2 Group Definitions Lower Display Prompt

Introduction Control 2 group prompts

PV 2 SRC

Input Input Algorithm Force MA PID Sets

Only TWO Three

RSP SRC Autobias Sptrack

OUT HiLIM OUT LoLIM

Revrse Disabl Enable

Hi LIM Lo LIM

128 UDC 3300 Process Controller Product Manual

Option group prompts Lower Display Prompt

Selection with desired scaling

Options Group Definitions

No Auxiliary Output

DEV Output LSP AL1 AL2 PV2 OUTPT2 SP L2

AUX OUT

None To MAN To LSP To 2SP To 3SP To DIR

CB OUT2

No Digital Input Selections

Stop MAN FS

PV 2IN PV 3IN Rerun To RUN

To RSP RST FB

TRACK1 TRACK2

DIG DIG2 COM

DIG DIG 1 COM

Any Digital Input Selection Plus RUN Setpoint

Digital Input 2 Selections

13 Communications Group Definitions Lower Display Prompt

Introduction Communications group prompts

ComSTATE Com Addr ComADDR2

Shed Enab

Wsfloat

Shedtime Parity Baud Duplex

Even Parity

Shed SP

Last Toauto Fsafe

To LSP To CSP

Percnt ENG

138 UDC 3300 Process Controller Product Manual

14 Alarms Group Definitions Lower Display Prompt

Introduction Alarms group prompts

A1S1 VAL A1S2 VAL A2S1 VAL

Alarm on Manual Mode Loop 1 Note

No Alarm Input

A1S1TYPE

Event on SP Programming Event OFF SP Programming

A1S2TYPE A2S1TYPE A2S2TYPE

High Alarm LOW Alarm

High LOW Begin END

Beginning of Segment END of Segment

AL Hyst ALM OUT1 Block

How to configure alarm to turn on and off with HealthWatch

Display Group Definitions

Introduction Display group prompts Lower Display Prompt

Decimal DECIMAL2 Temp Unit PWR Freq Ratio

Maintenance Group Definitions

Maintenance Group

Calibration Data

Input Calibration in this manual for complete information

Gsoak Sootng DIGIN1 DIGIN2 MAN2

TIME1

COUNTS1 COUNTER2 COUNTS2 COUNTER3 COUNTS3 Password RES Type

Failure. Refer to the Troubleshooting in this manual for

Status Test Data

Complete information

Operation

How to Power Up the Controller

Key Pressed Lower Display

Keys Procedure for Testing the Displays and Keys Press

Step Procedure for Entering a Security Code Press Action

Introduction Security code numbers Procedure

Entering a Security Code

Until you see

Operator interface

Monitoring Your Controller

Decimal point position

Degrees Fahrenheit Degrees Celsius

Automatic Mode MAN-Manual Mode

Annunciators

Lower Display Key Parameter

Viewing the operating parameters

BIA Tune OFF Tune RUN

Error Messages Description

Diagnostic error messages

Start-up procedure is given in Table

Start-up Procedure

Enter the local

Setpoint

Operating Mode Definitions

Available modes Mode definitions

Operating Modes

Remote Setpoint Manual Cascade Automatic Cascade

Changing Operating Modes Mode Change

What happens when you change modes

SP 2SP 3SP RSP CSP

Selecting manual or automatic mode

Position proportional backup mode

Introduction Selecting the local setpoint source

Setpoints

Hold

Changing local setpoint 1, 2, or

Setpoint selection indication

Enabling or disabling the remote setpoint

Setpoint Ramp Rate

Configuration Operation

14 Procedure for Configuring a Setpoint Ramp Step Operation

Configuring the setpoint ramp Procedure

Single Setpoint Ramp

SP Ramp

UDC 3300 Controller Product Manual 165

15 Procedure for Running a Setpoint Ramp Step Operation

Running the setpoint ramp Procedure

UDC 3300 Controller Product Manual 167

Introduction Select two sets or gain scheduling

Using Two Sets of Tuning Constants

Set tuning constant values for each set

Set switchover value

Rate Rset

RSET2

= 1 or

Introduction Procedure for displaying the alarm setpoints

Alarm Setpoints

Introduction Selections

Two Loops of Control Overview

21 Control Loop Selections Input Input Algorithm

Loop

Functional overview

Loop 1 and Loop 2 of a dual loop controller

Override rules

Internal cascade

Is a block diagram of the Hi/Lo Override Selector

Model DC330E-KE-5XX

Two-loop restrictions

24 Procedure for Selecting 2-loop Algorithm Step Operation

Configuring Two Loops of Control

25 Procedure for Selecting Output Algorithm Step Operation

Select the output algorithm for each loop

Select control parameters for each loop

Procedure in -26 shows you how select the 2 loop algorithm

Select tuning parameters for each group

Procedure in -27 shows you how select the Tuning Parameters

27 Procedure for Selecting Tuning Parameters Step Operation

Monitoring Two Loops of Control

Indicator

28 Digital Display Indication-Two Loops

Loop Indication

Loop operation

Operating Two Loops of Control

Operating modes and setpoint source Keyboard operation

Three Position Step Control Algorithm

Power-up output

Three Position Step Control algorithm Loop 1 only allows

Accutune Tune will operate with this algorithm

Introduction Input algorithm selections

Input Math Algorithms

Segment characterization Totalizer function

Xn Value Yn Value

Alarm on totalizer value Totalizer reset via digital input

Introduction Action on closure

Digital Input Option Remote Switching

30 Digital Input Option Action on Contact Closure

To RUN

Timer AM STA

Stop MAN FS

TRACK1 TRACK2

Will occur when the digital input is active

Means that the parameter is configured and the action

Display Indication

Action on contact closure

Digital Inputs 1 and 2 Combination Action Example

Introduction Function

Auto/Manual Station

State DI #1 Open DI #1 Closed

Description Configuration

Refer to -33 and set up the controller in the order shown

Up Group Function Prompts

Press To Enter Remarks

Up Group Function Prompts Press To Enter Remarks

Step Press

Value or Selection Algorithm

Options

Fuzzy Overshoot Suppression

Introduction How it works Configuration

Accutune

34 is a list of rules for Accutune

How Tune demand tuning works

Rules

34 Accutune Rules and Regulations Applicable Rule

35 Procedure for Starting Tune Demand Tuning Step Action

Starting Tune demand tuning

Switch to Automatic mode by pressing the MANUAL/AUTO key

Setpoint changes

Using Tune at start-up for duplex heat/cool

37 Procedure for Using SP Tuning at Start-up

Using SP tuning at start-up

Step Action

MANUAL/AUTO

SP tuning after start-up Aborting SP tuning

Using SP tuning at start-up for duplex heat/cool

Retuning

Values are entered and used until retuning occurs again

Error prompt accessing procedure

Key to return to manual mode. This will

Error prompt Upper Display Prompt

39 lists the Accutune error prompts and their definitions

39 Accutune* Error Prompt Definitions Action to Take

Carbon Potential

Introduction Features

Carbon Potential Control

Diagram

UDC

See .18 Maintenance for details on using the various

When the desired threshold is reached

HealthWatch maintenance alarms

HealthWatch

Fill out the worksheet

What is programming? Review program data and configuration

What’s in this section

Program Contents

UDC 3300 Controller Product Manual 207

Ramp unit

Ramp/Soak Profile example

Drawing a Ramp/Soak Profile

Segment Value Prompt

Program Record Sheet

Setpoint Program Data Entry Procedure Press Result

Make sure SP Ramp and SP Rate are disabled first

Alarms on the setpoint program Prompt hierarchy

Entering the Setpoint Program Data

Value or Selection use or

Prompt Hierarchy and Available Selections

SEG2 SP SEG2TIME SEG3RAMP SEG3RATE

Definition Value or Selection use or

SEG8 SP SEG8TIME SEG9RAMP SEG9RATE SG10 SP SG10TIME

SG11RAMP SG11RATE SG12 SP SG12TIME

Introduction Run/monitor functions

Run/Monitor the Program

Local Setpoint Value

Set the Local Setpoint

# RA

Viewing the number of cycles left in the program End Program

Power-up state

Result/Action

Procedures for Changing a Running Setpoint Program Function

218 UDC 3300 Controller Product Manual

Introduction What’s in this section

Input Calibration

Honeywell Radiamatic Type RH Type RI

Minimum and Maximum Range Values

RTD

IEC Alpha=0.00385 Ohms Ohms low Linear

Preliminary Information

Disconnect the field wiring

Calibration steps

Equipment Needed Type of Input

Equipment needed

Thermocouple inputs using an ice bath

Input #1, #2, or #3 Set Up Wiring

Input

Thermocouple inputs using a precision resistor

RTD inputs

Wiring Connections for RTD

Volts only Input

Radiamatic, millivolts, or volts except 0 to 10 volts inputs

To 10 volt inputs

Wiring Connections for 0 to 10 Volt Inputs

To 20 mA inputs

Input 3-Wire terminals as shown below

250Ω Resistor Assy

Copper Leads To 20 mA Source

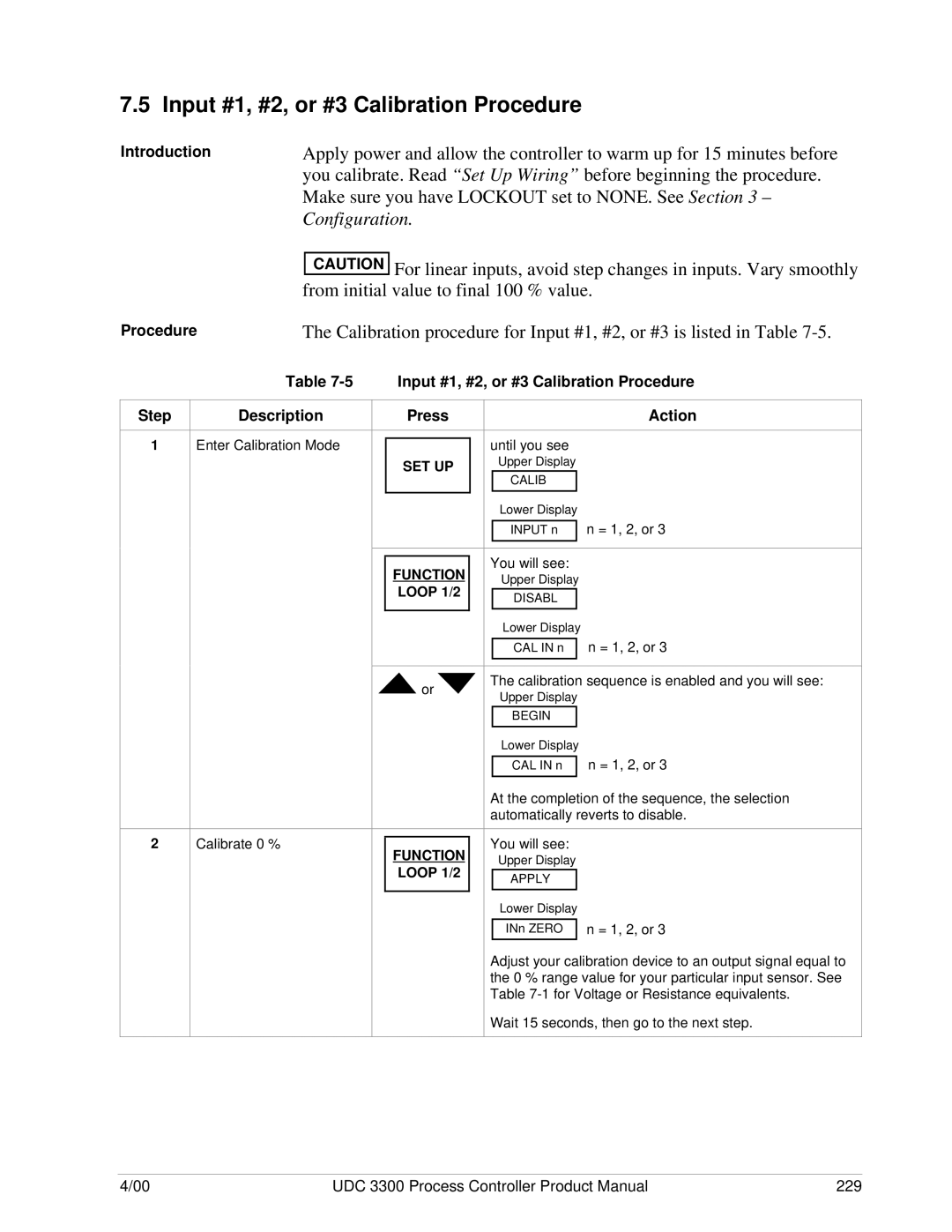

Input #1, #2, or #3 Calibration Procedure

Input #1, #2, or #3 Calibration Procedure

Make sure you have Lockout set to NONE. See Section

From initial value to final 100 % value

If… Then…

Step Description

Restoring Factory Calibration

How to restore it Procedure

Restoring Factory Calibration Step Operation

Action/Result

Step Operation Press

Output Calibration

Between 0 mA and 21 mA

Current Proportional Output Calibration

Equipment needed Calibrator connections

NONE. See Configuration

Make sure Lockout in the Tuning Set Up group is set to

Rules for auto mode vs manual mode Displayed values

Lockout in Tuning Set Up group is set to NONE. See Section

Procedure for calibrating the Position Proportional output

Procedure

These prompts only appear when position OUT ALG is

Do Auto

Do Auto or

Do MAN

Desired span value

Lower Display SET UP

Auxiliary Output Calibration

Set Up Wiring Procedure for Auxiliary Output Step Action

Any other values between 0 mA and 21 mA

Value between 0

Auxiliary Output Calibration Procedure Press Action

242 UDC 3300 Controller Product Manual

Troubleshooting / Service

Application related problems

Installation related problems

Hardware and software related problems

Error Message Prompts

Troubleshooting Aids

Status

Number

What happens at power-up

Power-up Tests

Power-up Tests Upper Display

Test failures

Status Tests

Introduction How to check the status tests

RAM Test Conf Test CAL Test Fact CRC

RAM Test Conf CAL Test Fact CRC

Status Tests

Fail

Pass

Introduction Background tests

Background Tests

EE Fail

INP1FAIL INP2FAIL INP3FAIL

INP1 RNG INP2 RNG INP3 RNG PV Limit RV Limit

Lower Display Reason for Failure How to Correct the Problem

PV = INP1 + INP1 Bias

RV = INP2 X Ratio + Bias

Compare your symptoms with those shown in -7 and refer to

Controller Failure Symptoms

Troubleshooting procedure indicated to correct the problem

Reacting

Equipment needed Procedure #1

Troubleshooting Procedures

Troubleshooting Power Failure Symptoms Step What to do

How to do it

Procedure #2

Procedure #3

Procedure #4

Procedure #5

Procedure #6

13 explains how to troubleshoot Alarm Relay Output failure

Procedure #7

14 explains how to troubleshoot a Keyboard failure

Procedure #8

15 explains how to troubleshoot a Communications failure

Introduction Equipment needed

Parts Replacement Procedures

16 How to Remove the Chassis Step Action

How to remove the chassis

How to replace the display/keyboard assembly

Refer to -2 and follow the procedure listed in Table

18 Printed Wiring Board Removal from Chassis Step Action

How to remove the printed wiring boards from the chassis

On Digital Input and MCU/Output boards

Printed wiring board identification

MCU

Prom

Power input board

19 Second Input Board Replacement Procedure Step Action

20 Power Input Board Replacement Procedure Step Action

2nd input board

Digital input board

21 Digital Input Board Replacement Procedure Step Action

Aux.Out/ communications board

Current Output-P/N Relay Output-P/N

23 MCU/Output Board Replacement Procedure Step Action

MCU/output board

Cleaning

Maintenance

There is a list of parts not shown in Table

Exploded View

Parts not shown

Parts identification

Key Part Number

Description Quantity

Appendix a Manual Tuning

Time, Position, or Current Proportional Simplex Control

Manual Tuning Procedure for Simplex Control

To Reduce Overshoot

Manual Tuning Formulas Units

Tuning function prompts for HEAT/COOL are

Two Sets of Tuning Parameters for Single Output Operation

PB or Gain

Rsetmin or Rsetrpm RSET2MIN or RSETRPM2

Index

278 UDC 3300 Controller Product Manual

Y, Z

280 UDC 3300 Controller Product Manual

Page

Sensing and Control

![]() or

or ![]()