This document supports firmware version 2.2 and above

Page

Warranty

How to Reach Customer Service

TEK-WIDE

Table of Contents

Tutorial

Table of Contents

Menus

Gpib

Theory of Operation Glossary Glossary-1 Index Index-1

List of Figures

List of Tables

Safety

SMA Connectors

Behavior of Outputs Turning Power On or Off

Do Not Remove Instrument Covers

Static Sensitive Device Notice

How This Manual is Organized

Conventions

Related Manuals

Xvi

Getting Started

GB1400 Pattern Generator and Error Detector

Features

Symmetrical, Low-Jitter Output Waveforms

Applications

Prbs Or User-Defined Test Patterns

Sample Applications

Adjustable Inputs For Maximum Flexibility

Auto Search For Easy Setup

Powerful Analysis And Reporting Functions

Burst Mode

Ordering Information

GigaBERT GB1400

GB1400T

GB1400R

GB Comparison GB660/CSA907A GB700 GB1400 Feature Tx and Rx

GB1400 Instrument Configurations Standard and Burst Option

GB1400 with Burst Option

Initial Self-Check Procedure

Procedure

Page

Operating Basics

Functional Overview

Bert Basics GB1400

Example, Bert Application

Clock Data

Controls, Indicators and Connectors

Front Panel, GB1400 Generator Tx

Front Panel, GB1400 Analyzer RX

Display Formats

1405000 PN23

Generator Tx Display

Frequency kHz Pattern Output

Frequency kHz Error Rate Totalize

Delay/ Memory

1405000 0E-06 2410538 PN23

Analyzer RX Display

Page

= clock bar = not clock

Generator Output Connectors Section

Outputs and Inputs

Generator Clock Section

Generator Output Section

Generator Rear Panel

Changing the Line Fuse

Analyzer Input Section

Analyzer Monitor Section

Analyzer Rear Panel

Connectors, Terminations, and Levels

DATA/DATA BAR

Controls and Indicators

Power Switches

Reset to Factory Default

View Angle and Panel Lock Keys

Gpib Section Controls

Pattern Controls and Function Keys

Function Soft Keys F1, F2, F3, and F4

Analyzer Inputs

Generator Error Inject Section

Affected Input Allowable Control

Analyzer Error History Section

Sync Loss

Analyzer Error Detection Section

Analyzer Sync Controls

Burst Mode Option

Burst Mode Usage

Specifications for Burst Mode

Transmitter Burst Mode Option

Data Value

ECL Levels Pecl Levels

Display Setting

Pecl Option for GB1400 Tx

Basic Bert testing with the GB1400

Key Feature of Tutorial

Objective of Tutorial

Equipment Required

Setup units with default settings

Instrument Connections and Controls

Setup Generator for PRBS-23 Mode

Connect the Generator to the Analyzer

Setup Analyzer for AUTO-SEARCH Operation

Change the Prbs pattern type

Turn off Auto Search and change Generator Outputs

Key several times to setup the analyzer for totalize

Data signal not detected. Selected

Your data signal

Error Rate display shows no Data or a 50% Error Rate

You are starting to detect the data signal

This Concludes the Tutorial

Applications

Two Auto Search Synchronization Methods

Phase

Application Note Auto Search Synchronization

Auto Search will find the Data V-THRESHOLD voltage

Auto Search will find the Data Delay

Auto Search Algorithm Fast Method

Auto Search will then attempt to find the Data Pattern

II. Auto Search Algorithm BER Method

Auto Search will find the Data Pattern and Polarity

Auto Search will determine the Data Delay

Page

Consideration In Determining The Data Eye Center

Delay Specifications

Consideration In Determining The Eye Data Width

GB700/ GB1400 Optical Component Test

Fiber Optic Link Test Example

Fibre Channel Link Testing Parallel and High-speed Serial

Testing Qpsk Modems, I & Q

Qpsk

Qpsk BER Testing using Prbs Data for 2-Channel I & Q

Channel Bert

Application Example

Reference

Turning Instrument Power ON/OFF

Menu Overview

Functions Common to Generator TX and Analyzer RX

Selecting 115 VAC or 230 VAC Operation

Recalling the Default Setup

Selecting a Pattern

Locking the Front Panel

Pattern Definitions

Selecting the Active Pattern

Selecting Prbs Patterns

Selecting the Current Word Pattern

Prbs 2n-1 Test Patterns

Selecting RECALLing a Saved Word Pattern

Word

Creating Word Patterns Using Front Panel Controls

Word Patterns

Basics

Standard Instruments

Instruments Equipped with 1-Mbit Option

Order

Creating Word Patterns Using Menus

Length Fill

Creating Word Patterns Under Remote Control

Saving Word Patterns 1-Mbit Memory Option

Recalling Word Patterns 1-Mbit Memory Option

Generator TX Functions

Clock Source and Frequency

External Clock Input

Clock Source

Saving a Frequency

Recalling a Frequency

Data and Clock Outputs

Overview

Generator Clock and Data Output Equivalent Circuits

Output Setup Rules vs. Termination Impedance

Amplitude and Baseline Offset

Logically Inverting Output Data D-INV

Procedure for Single-ended Operation TX only

Procedure for Differential Operation TX only

Single-ended or Differential Operation

Pattern Sync and CLOCK/4 Outputs

Error Injection

Selecting an Error Inject Mode

Data Inhibit Logic

Error Inject Input

Procedure to Control Error Injection Mode

Automatic Setup Functions Sync

Disable Key

Analyzer RX Functions

Auto Search Key

Actions Taken by Analyzer when Synchronization is Lost

Auto Search With Prbs Patterns

Auto Search with Non-PRBS Patterns

How to Disable Automatic Pattern Resynchronization

Relationship between Auto Search and Disable

Synchronization Threshold

Procedure to Set Sync Threshold

Synchronization Lock Threshold

Clock, Data, and Reference Data Inputs

Input Parameters

Input Data Delay

How F2 and F3 Determine Which Input Can be Set Up

Procedure to Add Delay

Controls

Input Terminations for CLOCK, DATA, and REF Data

Procedure for Selecting Input Termination

Input Termination

Input Threshold Range as a Function of Termination

Input Decision Threshold

Logically Inverting Input Data

Singled-ended or Differential Operation

Selecting the Reference Data Mode

Procedure for Selecting the Reference Data Mode

Output Setup

Monitor Outputs

Error Detection Set Up

BER

How Totalize Results are Measured

How Window Results Are Measured

How Test Results Are Measured

Window Measurement Process

Test Measurement Process

Display Mode Totalize, Window, or Test

Totalize Process Set Up

Procedure to Select a Results Display Mode

How to Tell Which Display Mode is Active

Window Process Set Up

Procedure

Test Process Set Up

BER and Bit Errors

Procedure to View Desired BER and Bit Error Results

Viewing Results

All Other Results Test Process only

Basic Report Setup Procedure

Printing Results Reports

Analyzer Setup Report

Example Analyzer Setup Report

Example End-of-Test Report

Procedure to Enable or Disable End-of-Test Reports

End-of-Test Reports

Example End-of-Window Report

Procedure to Enable or Disable End-of-Window Reports

End-of-Window Reports

On-Error Reports

Example On-Error Report

Procedure to Enable On-Error Reports

Procedure to Generate an On-Demand Test Summary Report

All Other Results Test Intervals Only

Result Definitions

BER = TE / TB

ES = TSE US

Error History Indicators

Analyzer performance history indicators are

Located in the Error History section of the front

Panel. These indicators will latch on when the indicated

Analyzer Error Messages

Procedure To Set Up the Audio Alert Function

Clear Control

Audio Beeper Function

Starting and Stopping Measurements

Procedure for Starting the Test Measurement Process

Procedure for Stopping the Test Process

Starting New Totalize and Window Measurement Intervals

Functions Performed Using the Menu System

Example Procedure Illustrating Menus and Functions

Menus

Menu and Function Pages

More Length Mode Report F1ESC F4SET Test Mode = Untimed

F1ESC F4SET Reports on = EOT/ERROR

General Rules for Using the Menu System

Menu Summaries

10. Menu Descriptions

11. Analyzer Menu System Overview

12. Generator Menu System Overview

Word

Menu Function Definitions

F1ESC F2- -F3 F4SET

Word AT ddddd = bbbbbbbb

Word Edit Edit

Format

Word Length

F1ESC F2- -F3 F4SET LENmmmmm Bytes + n Bits

Word Length Length

Fill Word Memory WITHhh

Word Fill Fill

Word Order

F1ESC F4SET Word Order = ccc First

Word Order Order

Word Sync

Word Sync Thres LEVEL= d

Word Synchronization Threshold Sync

Buffer

Buffer

Auto

Fast BER

Test Length

F1ESC F2- -F3 F4SET Test Length = hhmmss

Test Length Length

Test Mode

F1ESC F4SET Test Mode = ccccccc

Test Mode Mode

Test Report

F1ESC F4SET Reports on = ccccccccc

Test Reports Report

Test Thres

F1ESC F4SET Error Threshold = eeeee

Test Threshold Thres

Test Squel

On Error Squelch = ccc

Test Squelch Squel

Test Print Print

Test Print

Test VIEW-PRE

F1ESC F4SET result namecount %

Test View Previous VIEW-PRE

Test View Current VIEW-CUR

Test VIEW-CUR

Window Mode

F1ESC F4SET Window Mode = ccccccc

Window Mode Mode

Format

F1ESC F4SET Window LEN = 1.0eEE Bits

Window Interval in Bits Bits

Window Bits

Window Second

F1ESC F2- -F3 F4SET Window LEN = hhmmss

Window Interval in HrsMinSec Second

Window Report

END of Window Print = ccc

Window Reports Report

Baud

Baud = dddd

RS-232 Baud Rate Baud

Parity

F1ESC F4SET Parity = cccc

RS-232 Parity Parity

Size

Size = d

RS-232 Data Bits Size

EOL

F1ESC F4SET EOL = ccccc

RS-232 End-of-Line Char. EOL

XON/XOFF

F1ESC F4SET XON/XOFF Enable = ccc

RS-232 Xon/Xoff XON/XOFF

Echo

F1ESC F4SET RS232 Echo Enable = ccc

RS-232 Echo Echo

F1ESC F4SET Terminator = cccccc

Utility Option Option

Util Option

Utility Version VER

Util VER

Date

F1ESC F2- -F3 F4SET Date = mmm dd yy

Time Option Date

Time

F1ESC F2- -F3 F4SET Time = hhmmss

Time Option Time

Reference

Appendices

GB1400 Generator TX

Internal Clock Source

External Clock Source

SMA

Data Patterns

Data Output True and Complement

Rear Panel Auxiliary Outputs Phase A, Phase B, Clock/2

Error Injection

Clock Output True and Complement

NRZ-L

Mechanical

AC-Power Requirements

RS-232 and Gpib Interfaces

Data Input

GB1400 Analyzer

Clock Input

Reference Data Input

AUX

Synchronization

Measurements

BER

Printer Interface

Specifications

Bert Primer/ Technical Articles

Bert Building Blocks

Bert Definition

Bert used to test physical layer

Bert Pattern Generation

Prbs Patterns

Prbs

Prbs Generation Circuits a few sample diagrams

Doutput

Other Tx Patterns

Bert Receiver or Error Analyzer Components

Bert Clock

Output Amplifiers

Data Coding, NRZ

Error Comparator

Received Data Pattern Reference

Data Input Amplifiers

BER Computation

Confidence Requires Collecting Many Errors

Stress Testing

Confidence Level in BER Measurement

Additional Reading

Auto-Synch

Other Bert Features

Eye Width Measurement

Pattern Loading Software

Error Insertion

Pattern Lock

Jitter Generation

Bit error rate testing

How long is long enough?

BER

Ideal pulse

Stressing through pattern generation

Bert Technical Articles

Bert Technical Articles

Bert Technical Articles

Ensure Accuracy Of Bit-Error Rate Tests

Page

Supplying Data Patterns

Bert

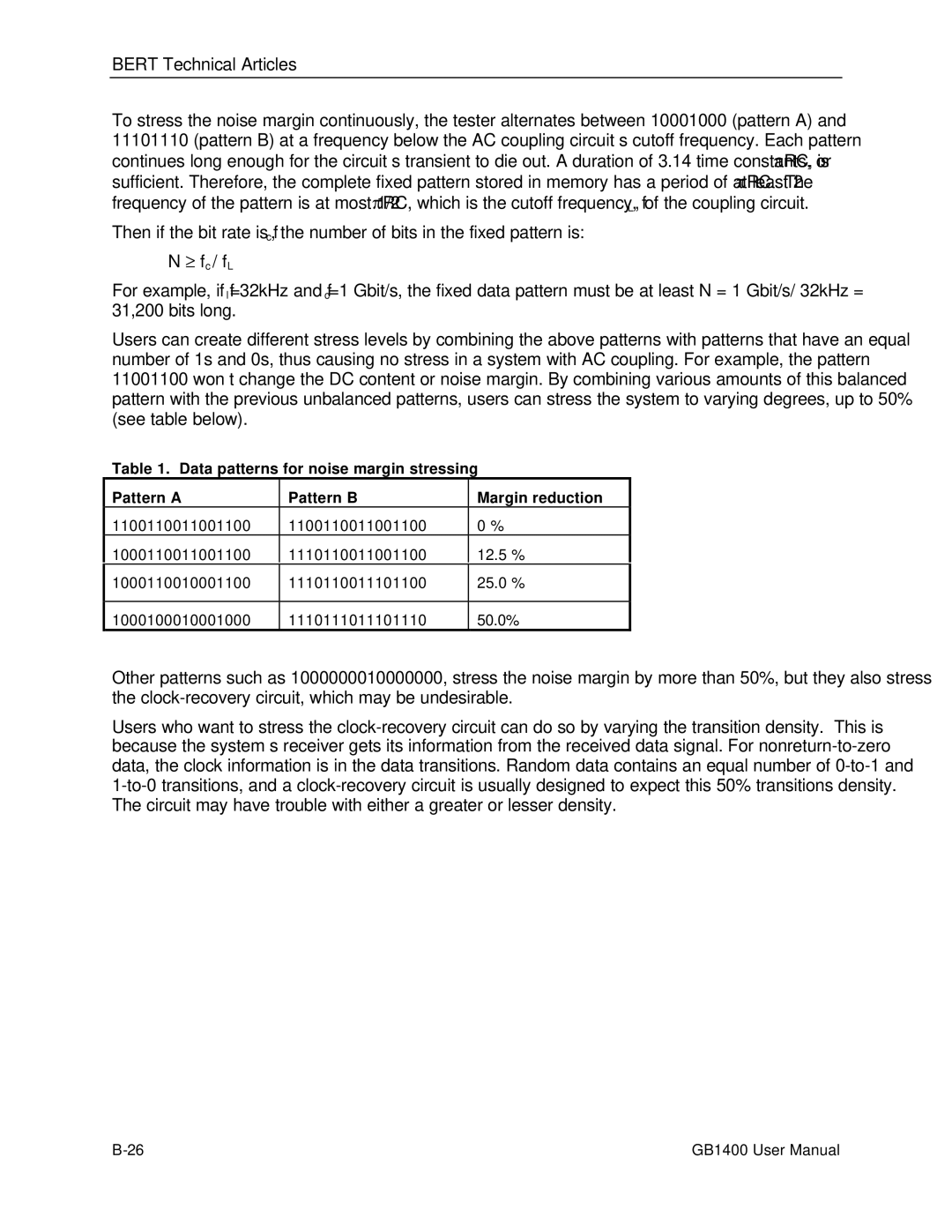

Noise-Margin Stressing

Μ F Avergage = Average =

Page

Data patterns for clock recovery stressing

Data Patterns Stored

+ Peak

Examining Jitter

2f BΦ θif B

Amplitude UI peak-to-peak Frequency

Jitter Tolerance

Bert Affects Accuracy

Example of Error Rate Measurement

Abstract

BER Measurement Inaccuracy versus Test Time

= n / T

Inaccuracy 95% = 2 σ / n ≈ 2/ n

Testing for an Upper Limit on Error Rate

Reduced Test Time by Stressing

SNR = 20 log S / N rms

Attenuation dB

Example

BER

Example

BER

Summary

Poisson Error Process

Pn = rT n e−rT . n

BER

Biography

Remote Commands

Type of Commands Starts on

Overview

Datathres

DATATHRES?

Command Line Rules

Command Line Terminator

Setting Arguments Outside of Legal Ranges

Command Examples

Command Summary Alphabetical

Bytesync n Analyzer only Bytesync?

Remote Commands

Rescurrate?

Tse?

Cls

Ese n

Idn?

Ese?

Esr?

Opc?

Lrn?

Opc

Rst

Sre n

Sre?

Stb?

Tst?

Wai

Tse v Analyzer Only

Tse? Analyzer Only

Tsr? Analyzer Only

Datapattern prbs word rdata

Datainvert onoff

Datainvert?

Prbslength?

Datapattern?

Prbslength

Wordbits l, b1 b2

Recallword m

Saveword m

Wordmemlen m, l

Wordbits?

Wordlength l

Wordmemord? m

Wordmemord m, msb lsb

Wordmemord?

Wordmemory m, l, b1, b2

Wordmemory? m

Wordorder msb lsb

Example Wordorder lsb

Page

Wordorder?

Memory allocation for Word Memory storage

Wordmemory?

Gpibbus offbus talklisten

Gpibaddress

Gpibaddress?

Gpibbus?

Rsecho onoff

Rsecho?

Rspmtlf onoff

Rspmtlf?

Rsprompt s

Rsxonxoff onoff

Rspmtlf on

Rsxonxoff?

Allmem?

Wordmemory 0, 16, #HAA, #HBB Wordmemory 1, 8, #HF0

Logo?

Header on off

Header?

Options?

Viewangle

Viewangle?

Viewangle

Clockmemory?

Clockfreq

Clockfreq?

Clockmemory m, f

Clockmemory? m

Clocksource intext

Clocksource?

Clockstep

Clockstep?

Clockstpup and clockstpdn

Clockstpup v and clockstpdn

Recallfreq m

Savefreq m

Clockampup and clockampdn

Amplitude

Amplitude?

Clockampup v and clockampdn

Clockampl

Clockampl?

Clockoffup and clockoffdn

Clockoffup v and clockoffdn

Clockoffset

Clockoffset?

Dataampup and dataampdn

Dataampup v and dataampdn

Dataampl

Dataampl?

Dataoffup and dataoffdn

Dataoffset?

Dataoffup v and dataoffdn

Dataoffset

Offset

Offset?

Errorsingle

Errorrate offextrate3rate4rate5rate6rate7

Errorrate?

Analyzer Commands

Resbits?

Rescurrate?

Resefs?

Resdm?

Resdmper?

Reselapsed?

Reserrors?

Resefsper?

Reslos?

Reses?

Resesper?

Ressesper?

Resphaes?

Resses?

Ressync?

Resstart?

Resstop?

Restotrate?

Restes?

Restesper?

Totalbits?

Resus?

Resusper?

Totaltime?

Totalerror?

Totalrate?

Clockterm neg2v gnd ac

Clockterm?

Datadelup and datadeldn

Datadelup v and datadeldn

Datadelay

Datadelay?

Dataterm neg2v gnd ac

Dataterm?

Datathres

Datathrup and datathrdn

Datathrup v and datathrdn

Rdatadelup v and rdatadeldn

Datathres?

Rdatadelup and rdatadeldn

Rdatadelay

Rdatadelay?

Rdataterm neg2v gnd ac

Rdataterm?

Rdatathres

Rdatathrup and rdatathrdn

Rdatathrup v and rdatathrdn

Rdatathres?

Autosearch auto off disab

Autosearch?

Automode ber, fast

Automode?

Autosample n

Autosample?

Autowidth?

Autothresh n

Autothresh?

Dispselect?

Errorreset

Dispselect total window test

Histrybits?

Histryclear

Histryphase?

Histrypower?

Histryphase on

Histrystat?

Histrysync?

Sync?

Testlength?

Testdiscard

Testlength t

Testprev currentprevious

Testmode untimedtimedrepeat

Testmode?

Testprint

Testreport eotonerrorbothnone

Testprev?

Testsquelch?

Testreport?

Testsquelch onoff

Teststate runstop

Teststate?

Testthres

Testthres?

Winerror?

Winbitlen

Winbitlen?

Winbits?

Winmode bitssec

Winmode?

Winprev currentprevious

Winprev?

Winreport?

Winrate?

Winreport onoff

Wintime?

Winseclen s

Winseclen?

Printport parallel gpib serial

Printenable onoff

Printenable?

Printport Parallel

Printport?

Printstring s

Audiorate

Audioratup and audioratdn

Audioratup v and audioratdn

Audiovol?

Audiorate?

Audiovol

Audiovolup and audiovoldn

Audiovolup v and audiovoldn

Date yyyy-mm-dd

Date?

Time s

Time?

MB Option Commands

Byteblock a, i, b1, ..., bn

Byteblock? a

Bytedelete a

Byteedit a, b1

Byteedit? a

Bytefill i, b1, b2, ..., bn

Byteinsert a, i, b1, ..., bn

Bytelength m, n

Bytelength?

Bytemode n

Bytemode?

Ratio errors/bits

Bytesync n Analyzer only

Bytesync? Analyzer only

Level

Editbegin n

Editcntrl?

Editend n

102

Using the Gpib Interface

Gpib Interface Device Settings

Interface Functions

Gpib Connector Pin-Outs

Programming Gpib Remote Commands

Status Byte

Gpib Numeric Responses

Gpib Status Reporting

Standard Event Status Register

Service Request Enable

Service Request SRQ

Test Status Event Register Analyzer only

Standard Event Status Enable Register

Test Status Event Enable Register Analyzer only

Gpib Common Commands

Additional SRQ Gpib Commands Rx only

Power-on settings

IEEE-488.2 Programming Manual Requirements

Specific Command Implementations

Overlapped vs. Sequential Commands

Functional Elements

Self Test Query

Using the RS-232 Interface Option

RS-232 Interface Device Settings

RS-232 Interface Testing

RS-232 Interface Hardware/ Handshaking Considerations

Programming RS-232C Remote Commands

RS-232C Error Messages

Using GPIB, RS-232

Customer Acceptance Test For GB1400 Generator & Analyzer

Performance Verification

Functional Test

Setup for Functional Test of Standard Instrument

Confirmation of Frequency Function

Confirmation of Generator Output Data Level Change

Confirmation of Error Injection Rates

Confirmation of Selectable Analyzer Terminations

Performance Verification

Confirmation of Buttons and Indicators

Panel Lock On OFF Addr

Returning to Factory Default Settings

How to Recall Factory Default Settings

Using Front Panel Controls

Via Remote Control

CLOCK/ Data Outputs

Generator TX Factory Default Settings

Data Pattern

Remote Interfaces

EOI/LF

CR/LF

Misc

Auto Search/Pattern Synchronization

Analyzer RX Factory Default Settings

Error Beeper

Time and Date

Printer

Current BER

Test Parameters

Misc

Cleaning the Interior

Cleaning the Exterior

Cleaning the CRT

Cleaning Instructions

Before You Begin

Pattern Editor Requirements and Features

What is MLPE?

List of Features

Minimum Requirements

If you are using an alternate shell, such as Norton Desktop

List of Files on this Disk

RS-232 Cabling

Page

Page

Read Before Opening Sealed Wrapper

Pattern Editing Software

Pattern Editing Software

Pattern Editing Software

Data Generator PCB

Design Overview

PLL Clock Source PCB

Data and Clock Output Amplifier PCB

GB1400 Analyzer RX

Input Amplifier PCB

Front Panel PCB

Error Counter PCB

Common to both GB1400 TX and GB1400 RX

GB1400 Tx

Figure I-2. Block Diagram GB1400 RX

Glossary/ Index

Bit Error

Address

Analog-to-Digital Converter

Attenuation

Error Detection

Bit Rate

Byte

Channel

Residual error rate

Multi-Channel Cable

Noise

RS-232C

Glossary-4

Auto Search

Appendices

Figures

Index-3

Tables