Srcp

Page

General Contents

Parameters

Iii

Communication with PC 11-1

Appendix 16-1

Memo

Overview

Chapter

Features of the Srcp Series Controller

Basic steps

Setting Up for Operation

Srcp controller

External View and Part Names

Exterior of the Srcp controller SRCP-05 SRCP-05A, 10A, 20A

Three-side view of the Srcp controller

2 TPB

System configuration

System Configuration

Peripheral options

Accessories and Options

Accessories

Memo

Installation and Connection

Installation location

Installing the Srcp Controller

Installation method

Connecting the power supply

Connecting the Power Supply

Power supply

Installing a circuit protector

Installing an external leakage breaker

Insulation resistance and voltage breakdown tests

Connecting the Srcp to the Control Unit

Installing current control switches

Grounding

Robot I/O connector and signal table

Connecting to the Robot

Connecting to the I/O. CN Connector

Slotted screwdriver Terminal numbers are not actually

Connecting to the EXT. CN Connector

Connecting the Srcp controller to a regenerative unit

Connecting to the Regenerative Unit

Memo

Interface

2 EXT. CN connector signals

I/O Signals

1 I/O. CN connector signals

Dedicated command input

Input Signal Description

Step operation start command STEP-R

Absolute point movement command ABS-PT

Relative point movement command INC-PT

Automatic operation start command AUTO-R

Reset command Reset

Return-to-origin command ORG-S

Servo recovery command Servo

PRM7

General-purpose input DI0 to DI7

Emergency stop inputs 1, 2 EMG1, EMG2

Service mode input Svce

Interlock Lock

Ready-to-operate output Ready

Output Signal Description

Command-in-progress output Busy

Dedicated output

Feedback pulse output PA±, PB±, PZ±, PZM±

General-purpose output DO0 to DO4

I/O Circuits

1 I/O circuit specifications

Circuit and connection example

2 I/O circuit and connection example

Connection to PLC output unit

I/O Connection Diagram

Connection to the Mitsubishi PLC AX41 input unit

Connection to PLC input unit

When turning the power on

I/O Control Timing Charts

When executing a dedicated input command

30ms or less 1ms or less 1ms or less 1ms or less

3When a command cannot be executed from the beginning

4When command execution cannot be completed

When interlock signal is input

When alarm is issued

When emergency stop is input

When executing a point movement command

Basic Operation of the TPB

When the power supply to the controller is turned on

Connecting and Disconnecting the TPB

Connecting the TPB to the Srcp controller

When the power supply to the controller is turned off

Disconnecting the TPB from the Srcp controller

Basic Operation of the TPB

Basic Key Operation

1MOD 2INS 3DEL 4CHG

Reading the Screen

Program execution screen

Program edit screen

CHG SPD

Point edit screen teaching playback

DIO monitor screen

PGM

Hierarchical Menu Structure

Explanation of access level

Restricting Key Operation by Access Level

Memory card

Changing an access level

1EDIT2OPRT3SYS 4CARD

Parameters

Parameters

Setting the Parameters

PRM2 soft limit

Parameter Description

PRM0 Robot type number

PRM1 + soft limit

PRM6 Positioning-completed pulse

PRM3 Payload

PRM4 Acceleration

PRM5 Return-to-origin direction

PRM10 Return-to-origin speed

PRM7 I/O point movement command speed

PRM8 No. of conditional input points

PRM9 Movf speed

PRM14 Overload current

PRM11 No. of encoder pulses 4 mode

PRM12 Lead length

PRM13 Origin detection method

PRM21 Position data unit

PRM18 Speed integration gain

PRM19 Position proportional gain

PRM20 OUT valid position

PRM27 Teaching movement data 1 for TPB

PRM24 Teaching count data TPB entry

PRM25 Not used

PRM26 Teaching movement data

PRM33 Operation at return-to-origin complete

PRM32 Alarm number output

Bit 6 Interlock function setting

PRM34 System mode selection

Bit 1 Ready signal sequence setting

Bit 3 Voltage check setting for system backup battery

PRM35 Origin shift

PRM38 Speed delay compensation gain

PRM39 Control mode selection

PRM40 Reset execution condition selection

PRM44 Maximum speed setting

PRM41 I/O point movement command speed

PRM42 I/O point movement command speed

PRM43 I/O point movement command speed

PRM49 Controller version

PRM47 Communication parameter setting

PRM46 Servo status output

PRM48 Pre-operation action selection

PRM53 Zone output selection

PRM51 Lead program number

PRM52 Hold gain

Zone output function

Zone setting range and output port

PRM58 Not used

PRM54 Magnetic pole detection level

PRM55 Magnetic pole position

PRM56 Controller version

Programming

Basic Contents

Editing Programs

EDIT-PGM

Creating programs after initialization

1EDIT2OPRT3SYS 4MON

1PGM 2PNT 3UTL

001MOVA 100 Point No0→999

1MOD 2INS 3DEL 4CHG EDIT-PGM

Creating a new program

PGM PNT UTL EDIT-PGM

Adding a step

EDIT-PGM No10 051JMPF 10 ,31 ,5

Movf

Correcting a step

MOD INS DEL CHG

Mova

1MOD 2INS 3DEL 4CHG

Inserting a step

MOD INS EDIT-PGM

Deleting a step

Copying a program

Program Utility

Deleting a program

EDIT-UTL

Viewing the program information

1COPY2DEL 3LIST

Editing Point Data

EDIT-PNT-MDI

Manual Data Input

Menu

1MDI 2TCH 3DTCH4DEL

Teaching Playback

EDIT-PNT-TCH1100 P500 = 167.24 mm 167.24 1CHG 2SPD3SSET4next

Direct Teaching

EDIT-PNT-DTCH

TRC

Manual Control of General-Purpose Output

1CHG 2DO 3BRK

Manual Release of Holding Brake

EDIT-PNT-DTCH

1CHG 2DO 3BRK EDIT-PNT-DTCH

Deleting Point Data

Tracing Points Moving to a registered data point

Robot Language

Jmpf

Robot Language Table

Robot Language Syntax Rules

Command statement format

Flag variable memory input/output 100 to

Variables

Point variable P

Counter array variable C, Counter variable D

Multi-task function

Program Function

Movi

Robot Language Description

Mova

Other

Movf

4 JMP

Jmpf

7 L

Jmpb

9 do

Call

Timr

Wait

Format Example Explanation

12 P

13 P+

14 P

Others

Srvo

Stop

Return-to-origin must be reperformed in this case

Orgn

Toff

18 TON

Condition is met

Jmpp

Fined

21 MAT

Msel

Robot

Movm

Jmpd

Jmpc

27 C

Csel

31 D+

28 C+

29 C

30 D

Shft

32 D

Moving at an equal pitch

Sample Programs

Moving between two points

Cancels job 1 command

Program Comment NO1

Point

Program Comment NO1 Main routine

Program description

Switching the program from I/O

Parameter

NO2

Axis movement and I/O multi-task

Turns DO0 off

When P1 is nearer to the plus side than P0

Memo

Operating the Robot

1ORG 2STEP3AUTO

Performing Return-to-Origin

Robot

Using Step Operation

OPRT- 010 001MOVA 999,50

SPD

OPRT-AUTO 100 0 0 001MOVA 254,100

Using Automatic Operation

Therobot

Switching the Execution Program

Initiating an emergency stop

Recovering from an emergency stop

Emergency Stop Function

Robot

Displaying the Memory I/O Status

Oprt

Displaying the Variables

Memo

Other Operations

1PGM 2PNT 3PRM 4ALL

Initialization

10-3

MON-DIO

DIO Monitor Display

Display from the monitor menu

1DIO 2DUTY

1EDIT2OPRT3SYS 4MON Information

System Information Display

Display from the DIO key operation

OPRT-AUTO

Service mode function

Limiting the robot movement speed

Safety settings for Service mode

Limiting command input from any device other than TPB

Hold-to-run function

Prohibiting the automatic operation and step operation

1ACLV2SVCE

Enabling/disabling the Service mode function

SYS-SAFE-SVCE-SET

Service mode = 0Invalid 1Valid

Setting the Service mode functions

1SAVE2CHG 3CANCEL

Viewing hidden parameters

System utilities

UP-ID

Using a Memory Card

Saving controller data to a memory card

1SAVE2LOAD3FMT 4ID

UP-SAVEAREA

UP-SAVE

Area UP-ID

Loading data from a memory card

UP-LOADAREA 3 Select menu

SYS-B.UP

Formatting a memory card

1SAVE2LOAD3FMT 4ID UP-ID

Viewing the ID number for memory card data

Method

Duty load factor monitor

10-21

Menu

Measuring the duty load factor

Saving the parameter data to the flash ROM

Using the internal flash ROM

1Manual load using the TPB or Popcom options

2Auto loading at Srcp power-on Auto-load function

FROM-SAVE

Saving the parameter data onto the flash ROM

1ALOD

FROM-SAVE

Operations

Manually loading the data from flash ROM

10-27

FROM-INIT

Initializing the flash ROM data

SYS-B.UP-FROM from

10-30

Communication with PC

PRM47 settings default value

Communication Parameter Specifications

Connector model computer side

Communication Cable Specifications

Connector model

Connector model controller side

Communication Command Specifications

Robot movement

Communication Command List

11-6

11-7

Transmission example

Communication Command Description

Robot movements

@ORG

Servo status

@RUN

@SRUN

@SRVO servo status

Axis position

@X+, @X

@XINC, @XDEC

@MOVD X-axis position mm,speed

10@MOVI point number,speed

@MOVA point number,speed

Point number

14@TIMR time

11@MOVF point number,DI number,DI status

17@P

15@P point number

16@P+

20@MSEL pallet number

18@MOVM pallet work position,speed

24@C- subtraction value

21@CSEL array element number

22@C counter value

23@C+ addition value

28@SHFT point number

26@D+ addition value

27@D- subtraction value

Data handling

@?ROBOT

@?STP program number

@?MEM

@?VER

12@?ERR history number,display count

11 @?ALM history number,display count

History number

Display count

16@?MODE

13@?EMG

14@?SRVO

15@?ORG

19@?DO general-purpose output or memory output number

17@?PVA

18@?DI general-purpose input or memory input number

21-1 @?P point number

20-1 @?PRM parameter number

Parameter number

20-2 @?PRM parameter number,parameter number

Number of steps

21-2 @?P point number,point number

22-1 @READ program number,step number,number of steps

Step number

22-5 @READ ALL

22-3 @READ PNT

22-4 @READ PRM

23-1 @WRITE PGM

22-6 @READ DIO

22-7 @READ MIO

22-8 @READ INF

23-3 @WRITE PRM

23-2 @WRITE PNT

25@?MSEL

23-4 @WRITE ALL

24@?MAT pallet number

28@?D

26@?CSEL

27@?C array element number

Element number

Utilities

@SINS program number,step number

@SWI program number

@SWITSK task number

Task number

@SMOD program number,step number

@SDEL program number,step number

Number of points

@DEL program number

@PDEL point number,number of points

Message Tables

Command error message

Error Messages

Error message specifications

Message Soft limit over Cause

Operation error message

Program error message

Multi-task error message

System error message

TPB Error Messages

Stop messages

Message specifications

Stop Messages

Displaying the Error History

1ALM 2ERR

12-10

Troubleshooting

If a Trouble Occurs

What you were using

To cancel the alarm

Alarm and Countermeasures

Alarm specifications

If an alarm is issued

Alarm Message Meaning Possible Cause Action

Alarm message list

13-5

13-6

Relating to the robot movement

Troubleshooting for Specific Symptom

Troubleshooting for Specific Symptom

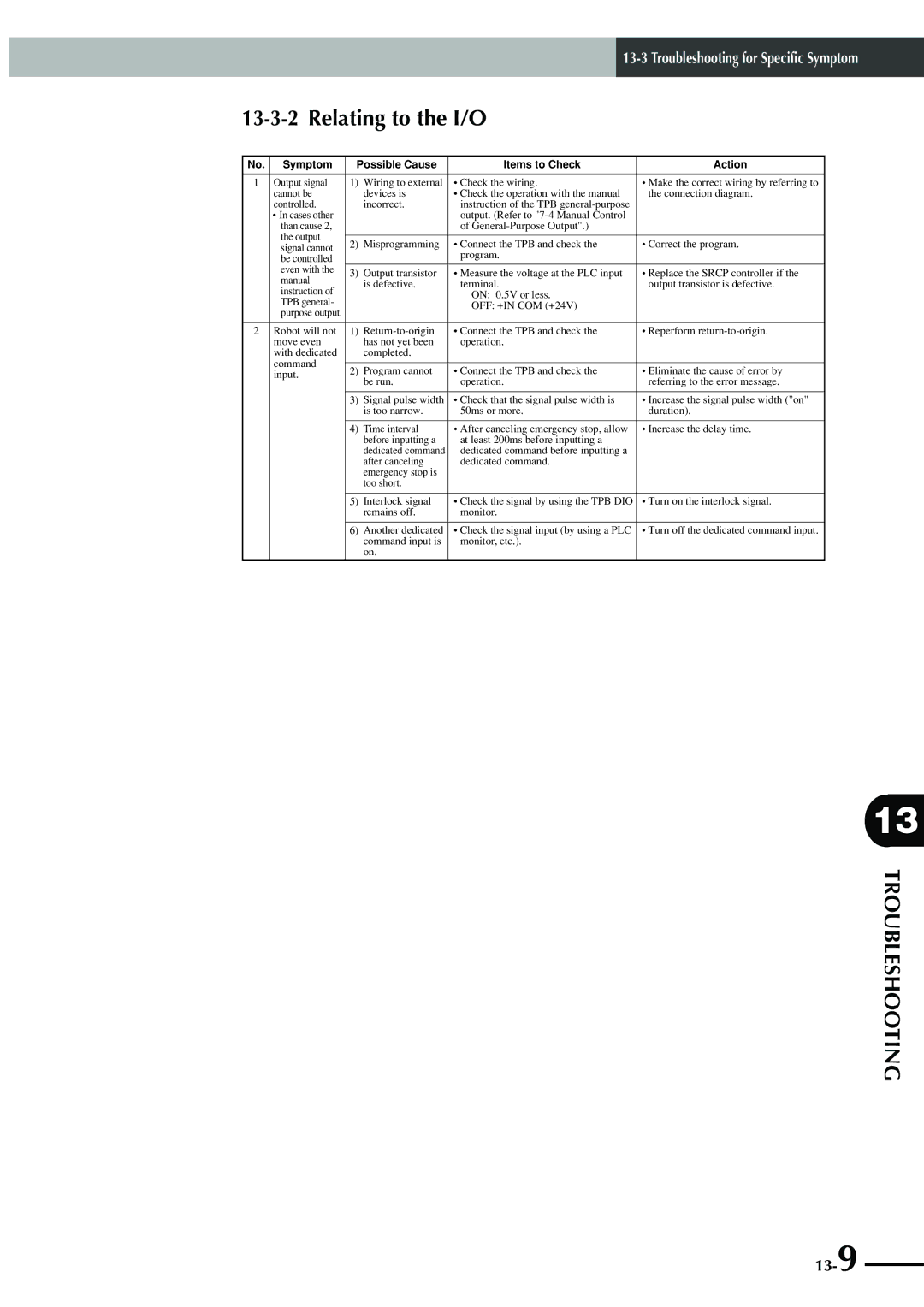

Relating to the I/O

TPB

Other

Displaying the Alarm History

13-12

Maintenance and Warranty

Exceptions to the Warranty

Warranty

Warranty description

Warranty Period

Battery product number CR2450THE Toshiba Battery

Replacing the System Backup Battery

Updating the System

Specifications

Srcp sereis

Basic specifications

LED display

Robot number list

TPB

15-2 TPB

Regenerative Unit RGU-2

15-6

Appendix

Memory card

How to Handle Options

Using the memory card

Precautions when using the memory card

Data size that can be saved

Popcom communication cable

When the PC has a D-sub 25-pin connector

When the PC has a D-sub 9-pin connector

Memo

Revision record