Page

„ Who should use this manual

Using This Manual „ Contents of this manual

„ Important precautions

Please Read Prior to Installation for Safety

Wiring

Installation

Maintenance and Inspection

Main Circuit Wiring

Main Circuit Terminal Wiring

Table of Contents

Display and Operation

Trial Run and Tuning Procedure

Control Modes of Operation

Maintenance and Inspection

Specifications 11-1

About this Manual… User Information

Technical Support and Service

This page intentionally left blank

„ Ensure that the product is what you have ordered

Unpacking Check

„ Ensure that the servo motor shaft rotates freely

„ Check for damage

Delta AC Servo Drive and Motor

Ecma Series Servo Motor

Model Explanation Nameplate Information

ASDA-B Series Servo Drive

Model Name Explanation

Unpacking Check and Model ExplanationASDA-B Series

Servo Drive and Servo Motor Combinations

Servo Drive Features

Control Modes of Servo Drive

Storage Conditions

Installation Notes

Operating Temperature

Installation Conditions

Installation Procedure

Installation Procedure and Minimum Clearances

Drive Mounting

Motor Mounting

„ Minimum Clearances

„ Side by Side Installation

Connections Connecting to Peripheral Devices

Connections and Wiring

CN1

Servo Drive Connectors and Terminals

CN2

CN3

Wiring Notes

Single-Phase Power Supply Connection

Wiring Methods

Housing Jowle C4201H00-2*3PA

Motor Power Cable Connector Specifications

Housing Jowle C4201H00-2*2PA

Case Ground BRAKE1 BRAKE2

Motor Model Name Encoder Connector Terminal Identification

Encoder Connector Specifications

GND Braid

Sheld

Cable Specifications for Servo Drive and Servo Motor

Basic Wiring Schematic of 400W and below models

Basic Wiring

Basic Wiring Schematic of 750W models

Basic Wiring Schematic of 1kW and above models

1 CN1 Terminal Identification

Input / Output Interface Connector -CN1

General Signals Pin No Details Wiring Diagram Refer to

Signals Explanation of Connector CN1

Vref

Tref

SON ALL

Srdy ALL

Zspd ALL

Tspd ALL

Warn ALL

Source of Torque Command

Source of Speed Command

Default DI Signals and do Signals

User-defined DI and do signals

User-defined DI and do signals

Connections and WiringASDA-B Series

Wiring Diagrams of I/O Signals CN1

VDD

Connections and WiringASDA-B Series

Connections and WiringASDA-B Series

Encoder Connector CN2

Selection Do not connect this terminal

CN3 Terminal Signal Identification

„ Connection between Keypad and CN3

Connection between PC/Keypad and Connector CN3

„ Connection between PC and CN3

Standard Connection Example Position Control Mode

Speed Control Mode

Torque Control Mode

This page intentionally left blank

ASD-PU-01A Description of Digital Keypad ASD-PU-01A

Display and Operation

Name Function

Monitor Mode

YES

Press Mode key to return to previous display

YES

Fast Edit Mode Fast Editing, Static & Dynamic Auto-tuning

Fast Editing

Abort Setting Display

Status Display Save Setting Display

Fault Message Display

Polarity Setting Display

Monitor Setting Display

Following table lists the display examples of monitor value

Status Display S H

Fault Code Display Operation

S H

JOG Operation

CCW

0 6 F O T

Do Force Output Diagnosis Operation

0 9 M O T

DI Diagnosis Operation

Do Diagnosis Operation

Parameters Read and Write

Display and OperationASDA-B Series

ASD-PU-01B Description of Digital Keypad ASD-PU-01B

Display and OperationASDA-B Series

Display and OperationASDA-B Series

Display and OperationASDA-B Series

Display and OperationASDA-B Series

Display and OperationASDA-B Series

Display and OperationASDA-B Series

Fast Edit Mode Fast Editing Function

Dynamic Auto-tuning Mode Dynamic Auto-tuning Function

Static Auto-tuning Mode Static Auto-tuning Function

Status Display Save Setting Display

Monitor Setting Display

Display and OperationASDA-B Series

Fault Code Display Operation

Display and OperationASDA-B Series

Do Force Output Diagnosis Operation

DI Diagnosis Operation

Do Diagnosis Operation

Parameters Read and Write

Display and OperationASDA-B Series

This page intentionally left blank

Inspection without Load

Trial Run and Tuning Procedure

Trial Run and Tuning ProcedureASDA-B Series

Over voltage

Applying Power to the Drive

Emergency stop activated

Encoder error

Reverse limit switch error

Undervoltage

Forward limit switch error

Overcurrent

Input power phase loss

Magnetic field error

JOG Trial Run without Load

ASD-PU-01A Tuning Flowchart

ASD-PU-01B Tuning Flowchart

Step

Speed Trial Run without Load

P1-11 is set to

„ ASD-PU-01A

Tuning Procedure

„ ASD-PU-01B

Tuning Procedure

Tuning Procedure Display Message

Tuning Flowchart

Load Inertia Estimation Flowchart

AutoMode PI Tuning Flowchart

Trial Run and Tuning ProcedureASDA-B Series

Trial Run and Tuning ProcedureASDA-B Series

Limit of Load Inertia Estimation

Relationship between Tuning Modes and Parameters

KVP

Gain Adjustment in Manual Mode

Trial Run and Tuning ProcedureASDA-B Series

This page intentionally left blank

Control Modes of Operation

Control Modes of Operation

PTT

Command Source of Position Control Mode

External Pulse Input Type Communication Addr H

ASD-PU-01A ASD-PU-01B

Inhibit

Structure of Position Control Mode

Electronic Gear Ratio

Pulse Inhibit Input Function Inhp

Inhp OFF

GR4

Electronic Gear Ratio Denominator Communication Addr DH

GR2

Low-pass Filter

Position Loop Gain Adjustment

Pflt

PF LT

PFG

KPP

PPR

PFF

KPF

REF-GND

Command Source of Speed Control Mode

Basic Structure

Structure of Speed Control Mode

Curve Filter

Smoothing Strategy of Speed Control Mode

Tacc

Acceleration Time Communication Addr H

Deceleration Time Communication Addr H

Tdec

TSL

Accel /Decel S-curve Communication Addr H

Sflt

Analog Speed Command S-curve Filter

Analog Speed Command Low-pass Filter

VCM

Max. Analog Speed Command or Limit Communication Addr H

Analog Speed Input Scaling

Speed Loop Gain Adjustment

Timing Chart of Speed Control Mode

SPD0 OFF

SPD1 OFF SON

PI Structure P2-32

„ Manual Mode

„ Auto Mode

AUT2

Tuning Mode Selection Communication Addr H

Manual Mode

KVP

GDR

Proportional Speed Loop Gain Communication Addr H

KVI

Speed Feed Forward Gain Communication Addr H

SFG

Frequency Domain

KVI

KVI

Time Domain

SFG

Auto Mode Continuous adjustment

NCF

Resonance Suppression

Notch Filter Resonance Suppression Communication Addr H

DPH

Use Low-pass Filter to suppress resonance

NLP

Use Notch Filter to suppress resonance

Command Source of Torque Control Mode

Structure of Torque Control Mode

Tflt

Smoothing Strategy of Torque Control Mode

Analog Torque Input Scaling

TCM

Max. Analog Torque Command or Limit Communication Addr H

TCM0 OFF

TCM1 OFF SON

Control Modes Selection

Speed / Position Control Mode Selection

Mode

OFF Not Care

Torque / Position Control Mode Selection

Speed / Torque Control Mode Selection

Torque Limit

Others Speed Limit

„ Built-in Regenerative Resistor

Regenerative Resistor

„ External Regenerative Resistor

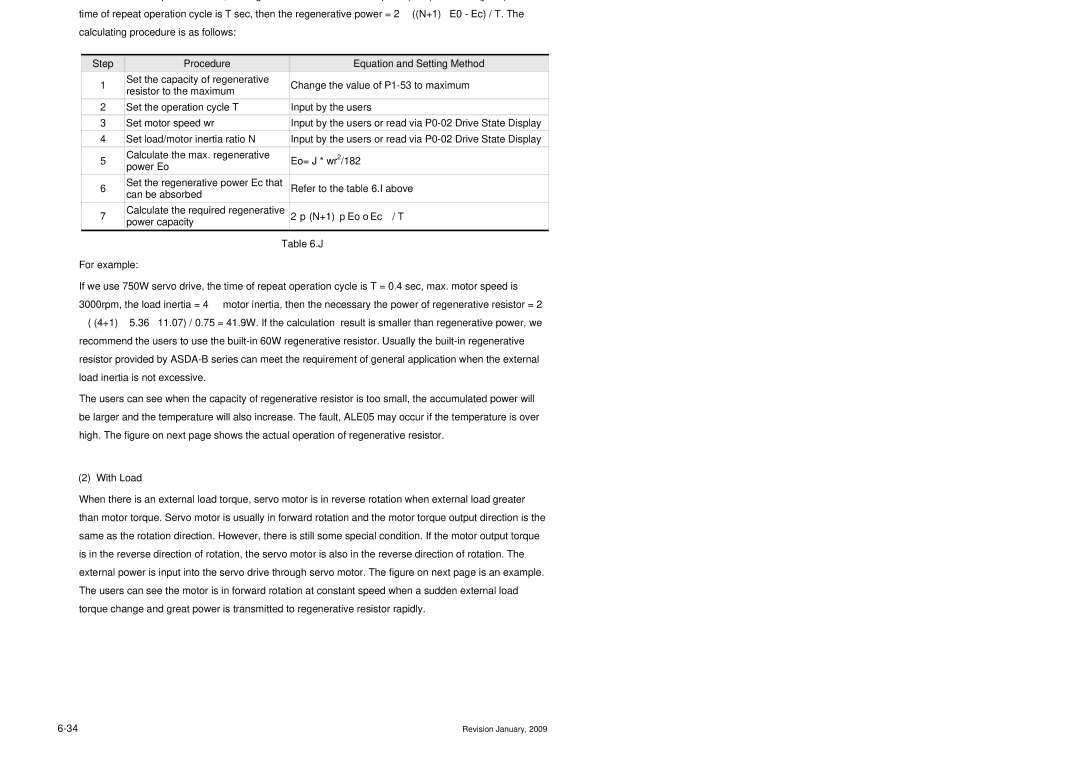

„ Regenerative Power Calculation Method Without Load

With Load

„ Simple Calculation Method

Electromagnetic Brake

Brkr OFF

OFF MBT1 MBT2

SON OFF

Control Modes of OperationASDA-B Series

Abbreviation of control modes

Explanation of symbols marked after parameter

Definition

Parameters Summary Parameters List by Group

Parameter Name Function Default Unit

Group 0 P0-xx

Control

Group 1 P1-xx

Control Parameter Name Function Default Unit Mode

Parameter Name Function Default Unit Mode

Group 2 P2-xx

Control Parameter Name Function Default Unit

AUT2

AUT1

Sdev

Pdev

Group 3 P3-xx

Group 4 P4-xx

Group 8 P8-xx

Monitor and General Use

Parameters List by Function

Gain and Switch

Position Control

External pulse control command P mode

Speed Control

Digital I/O

Communication

Input Status or Force Input Control P4-09

Others

Keypad Communication and Reset Setting P8-05

Detailed Parameter Listings

Drive Fault Code Communication Addr H

Group 0 P0-xx Monitor Parameters

VER

Servo ParametersASDA-B Series

Drive Status Communication Addr H

STS

Reserved Communication Addr H

CM1

CM3

CM2

Svsts

Servo Output Status Display Communication Addr H

Servo ParametersASDA-B Series

Group 1 P1-xx Basic Parameters

CTL

Control Mode and Output Direction Communication Addr H

Pstl

Speed and Torque Limit Communication Addr H

TCM1, TCM0

SPD1, SPD0

Aout

SPD3

SPD1

SPD2

TQ2

TQ1

GR4

Lstp

Tacc

Zspd

Zero Speed Range Setting Communication Addr H

Sspd

Target Rotation Speed Communication Addr H

MBT1

On Delay Time of Electromagnetic Brake Communication Addr AH

MBT2

GR1

Regenerative Resistor Capacity Communication Addr H

RES1

RES2

Positioning Completed Width Communication Addr H

PER

Mspd

Maximum Speed Limit Communication Addr H

KPP

SPR

Speed Loop Gain Switching Rate Communication Addr H

Pctlc

Bounce Filter Communication Addr H

DRT

DI1

Digital Input Terminal 1 DI1 Communication Addr AH

DI5

DI3

DI4

Digital Input Terminal 6 DI6 Communication Addr EH

DI6

DO1

Digital Output Terminal 1 DO1 Communication Addr H

Digital Output Terminal 3 DO3 Communication Addr H

DO3

External Anti-Interference Gain Communication Addr AH

DST

Gain Switching Time Constant Communication Addr CH

Gain Switching Control Selection Communication Addr BH

GCC

GUT

GPE

Gain Switching Condition Communication Addr DH

INH

AUT1

AUT2 Tuning Mode Selection

Sdev

Excessive Error Warning Condition Communication Addr H

Overspeed Warning Condition Communication Addr H

Pdev

Overload Protection Level Communication Addr H

OVL

OVW

Output Overload Warning Level Communication Addr H

Special Function Communication Addr H

Gbit

Afrq

Atur

Atme

Astr

Cclr

Pulse Deviation Clear Mode Communication Addr H

Sjit

Group 3 P3-xxCommunication Parameters

Communication Address Setting Communication Addr H

ADR

BRT

FLT

Transmission Fault Treatment Communication Addr H

CWD

Communication Time Out Detection Communication Addr H

CDT

SDI

Digital Input Communication Function Communication Addr H

ASH3

ASH2

ASH4

ASH5

JOG Operation Communication Addr H

JOG

FOT

Force Output Control Communication Addr H

MOT

Itst

Input Status or Force Input Control Communication Addr H

CEN

Adjustment Function Communication Addr AH

TOF1

SOF1

SOF2

COF2

COF1

COF4

COF3

Tigb

Igbt NTC Calibration Communication Addr H

Analog Speed Input Offset Communication Addr H

SAO

TAO

Analog Torque Input Offset Communication Addr H

CN1

Group 8 P8-xx Keypad Parameters

Keypad Communication and Reset Setting Communication Addr H

Kver

Keypad Firmware Version Communication Addr H

Transmission Speed Keypad Communication Addr H

Kadr

Kbrt

Kcmm

Kptl

Communication Selection Keypad Communication Addr H

Ktst

Memory Block Clear Communication Addr BH

Kblt

Kclr

Memory Block Position Number ROMx Communication Addr CH

Krno

KBL0

Status of Memory Block ROMx Communication Addr DH

Firmware Version of Memory Block ROMx Communication Addr EH

KBL1

Input Function Definition

Setting value of P2-10 ~ P2-15

Inhp is activated, the external pulse input command is not

SPD0 SPD1

Setting value of P2-10 ~ P2-15 14 ~

TCM0 TCM1

Setting value of P2-10 ~ P2-15 16 ~

Emgs

Tllm

Output Function Definition

Setting value of P2-18 ~ P2-20

OFF

Warn

Communication Hardware Interface

RS-232 „ Configuration „ Cable Connection

Modbus CommunicationsASDA-B Series

RS-485, RS-422 „ Configuration „ Cable Connection

Modbus CommunicationsASDA-B Series

Communication Parameter Settings

Modbus CommunicationsASDA-B Series

DI6 DI5 DI4 DI3 DI2 DI1

0307H Communication Response Delay Time

RTU Mode

„ Code Description Ascii Mode

Modbus Communication Protocol

„ Data Format

STX

„ Communication Protocol Ascii Mode

CMD

DATA0 LRC

Ascii Mode Command message Response message

CMD Command Codes and Data Data Characters

STX Communication Start

ADR Communication Address

ADR CMD

RTU Mode Command message Response message

Ascii Mode Command message

LRC Ascii Mode

End1, End0 Communication End Ascii Mode

CRC RTU Mode

Error Code RTU Mode

„ Communication Related Error Code

Modbus CommunicationsASDA-B Series

Modbus CommunicationsASDA-B Series

Basic Inspection

Maintenance and Inspection

Life of Replacement Components

Maintenance

„ Smooth capacitor

„ Relay

„ Cooling fan

This page intentionally left blank

Fault Messages Table

Display Fault Name Fault Description

Fault Messages

Keypad Fault Messages Display Fault Name Fault Description

ALE 20/ALE

ALE 2 / ALE Overvoltage

Servo Drive Fault Messages ALE 1 / ALE Overcurrent

Potential Cause and Corrective Actions

ALE 3 / ALE

Regeneration error

ALE 4 / ALE

Pulse shift

Overspeed

ALE 6 / ALE Overload

ALE 7 / ALE

ALE 10 / ALE Serial communication error

Abnormal pulse control command

ALE 8 / ALE

ALE 9 / ALE

ALE 12 / ALE Adjustment error

ALE 11 / ALE Encoder error Position detector fault

ALE 14 / ALE Reverse CWL limit switch error

ALE 15 / ALE Forward Ccwl limit switch error

ALE 17 / ALE Memory error

ALE 16 / ALE Igbt temperature error

ALE 19 / ALE Motor type error

ALE 20 / ALE Input power phase loss

ALE 31 LED hardware error

Keypad Fault Messages ALE 30 LCM hardware error

ALE 32 KEY hardware error

ALE 33 RAM hardware error

ALE 40 Initial setup error

ALE 35 Comm hardware error

ALE 42 Communication receive error

ALE 41 Communication receive time out

ALE 44 Error communication response command

ALE 43 Error communication response address

ALE 45 Communication parameter address error

ALE 46 Communication parameter content error

Display Fault Name Clearing Method

Clearing Servo Drive Faults

Specifications of Servo Drive ASDA-B Series

Specifications

SpecificationsASDA-B Series

11-3

Low Inertia Servo Motor

Specifications of Servo Motor Ecma Series

Medium / High Inertia Servo Motor

Revision January

Weight

Dimensions of Servo Drive

Order P/N ASD-B0721-A 750W

Order P/N ASD-B1021-A, ASD-B1521-A, ASD-B2023-A 1kW to 2kW

Servo Motor Speed-Torque Curves T-N Curve

„ Chart of load and operating time ECMAC30401…S

Overload Characteristics

„ Overload Protection Function

„ Occasion of Overload

„ Chart of load and operating time ECMAC30604…S

„ Chart of load and operating time ECMAC30602…S

„ Chart of load and operating time ECMAC30807…S

„ Chart of load and operating time ECMAC30804…7

„ Chart of load and operating time ECMAC31020…S

„ Chart of load and operating time ECMAC31010…S

„ Chart of load and operating time ECMAC31305…S

„ Chart of load and operating time ECMAC31303…S

„ Chart of load and operating time ECMAC31309…S

„ Chart of load and operating time ECMAC31306…S

„ Chart of load and operating time ECMAC31315…S

„ Chart of load and operating time ECMAC31310…S

„ Chart of load and operating time ECMAC31820…S

„ Chart of load and operating time ECMAC31320…S

Motor Frame Size 80mm Models

Dimensions of Servo Motor

Motor Frame Size 100mm Models

11-21

11.7 EMI Filters Selection

Application Example Dual Mode S-P Mode Purpose

Connecting to DVP-EH PLC and DOP-A HMI

Explanation Programmable Logic Controller hereinafter PLC

Y1 Sign

PLC Program

Application Examples ASDA-B Series

12-4

12-5

DVP-EH ASDA-B CN1

DVP-EH

Program Screen Homing Operation

HMI DOP-A HMI

Position Control

12-9

JOG Operation

Speed Control Operation

Delta TP04 Series

Connecting to DVP-EH PLC and Delta TP04 Series

Application Example Homing Operation Purpose

12-13

Communication Settings

ASDA-B series Servo Drive Parameter Settings

External Controller Connection Examples

„ Connecting to Delta DVP-EH PLC

„ Connecting to Delta DVP-01PU

„ Connecting to Mitsubishi FX1PG

„ Connecting to Mitsubishi FX2N1PG

„ Connecting to Mitsubishi AD75

This page intentionally left blank 12-20

Delta Part Number ASDBCAPW0100

„ Power Connectors Delta Part Number ASDBCAPW0000

Jowle

Delta Part Number ASDBCAPW0303/0305

„ Power Cables Delta Part Number ASDBCAPW0203/0205

Delta Part Number ASD-CAPW2303/2305

„ Power Cables, Delta Part Number ASD-CAPW1203/1205

Delta Part Number ASD-CAPW2203/2205

„ Encoder Connectors Delta Part Number ASDBCAEN0000

ASDBCAEN1003

„ Encoder Cables, Delta Part Number ASDBCAEN1003/1005

ASDBCAEN1005

Jaws

Appendix a AccessoriesASDA-B Series

Delta Part Number ASD-PU-01B including communication cable

ASDBCAEN0003 ASDBCAEN0005

ASDBCAPW0203 ASDBCAPW0205

200W Servo Drive and 200W Low Inertia Servo Motor

ASDBCAPW0203 ASDBCAPW0205 ASDBCAPW0303 ASDBCAPW0305

ASD-CAPW1203 ASD-CAPW1205 ASD-CAPW1303 ASD-CAPW1305

400W Servo Drive and 500W Medium Inertia Servo Motor

ASDBCAEN1003 ASDBCAEN1005

400W Servo Drive and 300W High Inertia Servo Motor

1kW Servo Drive and 1kW Medium Inertia Servo Motor

750W Servo Drive and 600W High Inertia Servo Motor

1kW Servo Drive and 1kW Low Inertia Servo Motor

2kW Servo Drive and 2kW Low Inertia Servo Motor

1kW Servo Drive and 900W High Inertia Servo Motor

5kW Servo Drive and 1.5kW Medium Inertia Servo Motor

2kW Servo Drive and 2kW Medium Inertia Servo Motor