00809-0100-4530, Rev BA July

Reference Manual

Page

North American Response Center

Page

Table of Contents

Configuration

Electrical Installation

Operation

Service Troubleshooting

Reference Data

Safety Instrumented Systems 4-20 mA only

Appendix a

Appendix F

Appendix C

Appendix

Appendix G

Appendix H

Section Introduction

Safety Messages

Explosions could result in death or serious injury

Electrical shock could cause death or serious injury

Manual Overview

Service Support

Product RECYCLING/DISPOSAL

Transmitter Overview

Signal Amplitude Reference Pulse Level Interface Level Time

Applications

Tank

5303

Lead

Components of the Transmitter

½ NPT

M50 nut Cable Remote Connection

Dual Compartment Housing Bolt Bracket

4-20 mA

System Architecture

20 mA/HART

Minimum load resistance 250 Ω within the loop is required

Host/DCS system e.g. DeltaV

Foundation Fieldbus system architecture

Rigid Single Flexible Single Coaxial

Probe Selection Guide

Flexible Twin

Tank Environment Considerations

Dielectric

Transition Zones

Flexible Single Lead Coaxial

Constant

Sticky applications, periodic cleaning may be required

Process Characteristics

Coating

Bridging Foam Vapor Boiling Hydrocarbons

Minimum Dielectric Constant at Maximum Measuring Range

Measuring Range

Interface

Upper product dielectric constant

Flexible Single Lead Product

Heating Coils, Agitators Tank Shape

Vessel Characteristics

Emulsion Layers

Lower product

Follow these steps for proper installation

Installation

Procedure

Rosemount 5300 Series

Process leaks could result in death or serious injury

Mechanical Installation

Rosemount 5300 Series

Considerations

Mounting

Process Connection

Threaded Connection

Recommended

Single Rigid/Flexible Coaxial

Nozzle Diameter D

Diameter D1 Recommended

Long Stud

Installation of Single Lead Probes Non-metallic Vessels

Metal flange Ø2 Metal sheet

In./DN50

Metal

Installation in Concrete Silos

Considerations for Solid Applications

Material

Mounting in Chamber/ Still Pipe

Polypropylene

Pellets Cement

Probe Type Recommended Diameter Minimum Diameter

Rigid Single

Rosemount 5300 Series

Replacing a Displacer An Existing Displacer Chamber

Considerations when changing to Rosemount

Required Probe Length Depending on Chamber Manufacturers

Rosemount 5300 benefits

Free Space

Inlet pipe Agitator Heating coils

Mounting Position

Recommended Mounting for Solids

Hthp version Tank insulation

Ambient Temperature F C

Insulated Tanks

Transmitter head Nut Bolts Flange Probe Gasket Tank flange

Qualified personnel perform the installation

Flange Connection

Transmitter head Nut

Threaded Connection

Flange nut Bolts Probe Gasket Tank flange

Nut Tank connection Probe Sealant on threads or

Tri-Clamp Connection

Bracket Mounting

Fasten the housing support to the bracket

Mount the bracket to the pole

Connect the transmitter head on the probe

Hthp Coaxial and Ptfe probes must not be shortened

Shortening the Probe

Flexible Twin/Single Lead

Rigid Single Lead

Rigid Twin Lead

Hthp coaxial probe must not

Coaxial

Be cut in field

Centering piece is

Flexible Twin/Single Lead probe with weight and magnet

Flexible Twin/Single Lead probe with weight and ring

Weight with internal threads M8x14 Ring Magnet

Anchoring

Rigid Twin Lead probe

Coaxial probe

Flexible Single Lead probe

Drain

≥ 1cm/m

Solid Applications

Alternative chuck for Flexible Single Lead probes

Mounting a Centering Disc on Flexible Single Probes

Mounting a Centering Disc for Pipe Installations

Secure the split pin

Mounting a Centering Disc on Rigid Single Probes

Rigid Single Lead probe 13 mm

Bushing

Rigid Single Lead probe 8 mm

Rosemount 5300 Series

Electrical Installation

Avoid contact with leads and terminals

Hazardous Areas

CABLE/CONDUIT Entries Grounding Cable Selection

Hart

Power Requirements Maximum Loop Resistance

Current

75 mA

Connecting the Transmitter

Communicator Radar Transmitter AMS Suite Hart modem

Non-Intrinsically Safe Output

Field

Approved is Barrier

Is parameters1

Ui=30 Ii=130 mA Pi=1 W Ci=7.26 nF Li=0

Approval Type Power Supply Vdc

Power Requirements

Power supplies

Grounding Foundation Fieldbus

Shield Wire Ground

Connecting Fieldbus Devices

Non-Intrinsically Safe Output

Ui=17.5 Ii=380 mA Pi=5.32 W Ci=0 Li=0

Ui=30 Ii=300 mA Pi=1.5 W ATEX, 1.3 W FM Ci=7.26 nF Li=0

Fisco is parameters

Tri-Loop Hart to analog converter

Optional Devices

DIN Rail Mounted Hart Tri-Loop Burst Input to Tri-Loop

Intrinsically Safe Barrier

Field Signal Indicator

Section Configuration

Overview

Rosemount 5300 Series

Measurement Units Tank and Probe Geometry

Basic Configuration Parameters

Mounting Type

Tank Height

Inner Diameter

Nozzle Height

Tank Environment

Measurement Mode

Hold Off/Upper Null Zone

Rapid Level Changes

Strapping Table

Volume Configuration

Tank Type

Vertical Cylinder

Standard Tank Shapes

Horizontal Cylinder

Vertical Bullet

Upper/Lower Range Value

Output Source/Primary Variable

Level MA Saturation Values MA Alarm Value

Alarm Mode

High 20.8 mA

High 20.5 mA 22.5 mA

Basic Configuration Using a 375 Field Communicator

Process Variables

Setup

Diagnostics/Tools

System Requirements Help In RRM

Basic Configuration Using Rosemount Radar Master

Hardware

Software

Getting Started

Installing the RRM software for Hart communication

To set the COM port buffers

Specifying the COM Port

Click the OK button

Restart the computer

Installing the RRM Software for Foundation Fieldbus

Select the Measurement Units tab

Specifying Measurement Units

Using the Setup Functions

Run Wizard

Guided Setup

General Information

Device Properties

Probe

Geometry Hart command 2, 1 Foundation Fieldbus parameter

Dielectric Constant/Dielectric Range

Process Conditions

Rosemount 5300 Series

Volume Offset

Volume

Tank Diameter

Tank Length

Analog Output Hart

Finish Configuration Wizard

Device Specific Configuration

View Measured Values

Backup

Restart the Transmitter

Rosemount 5300 Series

Configure/Setup

Basic Configuration Using AMS Suite Hart

Basic Configuration Using Deltav

Rosemount 5300 Series

Rosemount 5300 Series

Transducer 1100MEASMODE

See Volume Configuration on page 5-7for more information

Volume Offset Foundation Fieldbus parameter

Diameter Foundation Fieldbus parameter

Tank Length Foundation Fieldbus parameter

Assigning Device Tag and Node Address

Foundation Fieldbus Overview

Foundation Fieldbus Block Operation

Advanced Configuration Transducer Block

Level Transducer Block

Register Transducer Block

Outd

Analog Input Block

Function Block Summary

Direct

Configure the AI Block

Indirect

AI Block

Xdscale and Outscale

Indirect Square Root

Ltype is Direct

Ltype is Indirect

Signal Strength

Temperature

Engineering Units

Level Rate

Parameter Configured Values

Solution

Application Example

Radar Level Transmitter, Level Value

Level Measurement percent

Radar Level Gauge, Level value in percent %

100% 46 ft 14 m

Level Measurement

100% 10ft 3 m 33 ft 10 m

Function Block Interface Level Measurement

Function Block

Variable Units

TRI-LOOP Hart to Analog Converter

Variables Assignment

Control Room

To turn off the Burst Mode

DIN Rail Mounted

Hart MULTI-DROP Configuration

Rosemount 5300 Series

Section Operation

Error messages are listed in section LCD Error Messages on

Using the Display Panel

Viewing Measurement Data

Measurement value

Using Rosemount Radar Master RRM

Using a Handheld Communicator

Device Config General

Specifying Display Panel Variables

LCD tab

Using AMS

Using DeltaV

Parameter Presentation on display Description

LCD Parameters

LCD parameters and presentation on display

Presentation Analog Output value in RRM

Viewing Measurement Data in RRM

Viewing Measurement Data in AMS Suite

Level values Interface Level values

Viewing Measurement Data in DeltaV

Rosemount 5300 Series

Foundation Fieldbus Error Messages

Service and Troubleshooting

Explosions could result in death or serious injury

Distance, m

Analyzing the Measurement Signal

Rosemount 5300 Series

Amplitude, mV

Surface Pulse not Found

As product Surface Distance, m

Probe End Projection

Amplitude, mV Disturbing Echo Actual surface

Disturbance Echo Handling

Measurement signal

Amplitude Threshold Curve

Disturbances at the Top of the Tank

Interface Pulse not Found

Amplitude, mV Distance, m

Signal Quality Metrics

Device Config Tools

Using the Echo Curve Analyzer

Using the Rosemount Radar Master

Measure and Learn Set threshold

Configuration Mode Tab

Measurement Output

View/Record ModeTab

Record tank spectra Play continuously updates the spectrum

Advanced

Play

To adjust the amplitude thresholds

Threshold Settings

Record Tank Spectra

Viewing the Echo Curve

Rosemount 5300 Series

Product Level is ignored Interface Level is measured

Interface Measurements with Fully Submerged Probes

Interface Distance

Analog Output Calibration

Level calibration

Level and Distance Calibration

Distance calibration

Reference Point Distance Reference Gauge Height Level

12. Distance and Level calibration

Browse

Update rate Start Log

Logging Measurement Data

Backup File Reader

Backing UP Transmitter Configuration

Configuration Report

Factory Settings

Reset to Factory Settings

Choose the Factory Settings option

Rosemount Radar Master

Diagnostics

Status

Hart command

DeltaV

Choose the Simulation Mode option

RRM choose menu option ToolsSimulation Mode

Simulation Mode

Mode

Write Protecting a Transmitter

Enter Service Mode in RRM

Choose the Unlock/Lock Device option

Unlock/Lock

Viewing Input and Holding Registers

Nut Put the protection

Removing the Transmitter Head

Plug here

Put the protection Nut

Firmware Version

Changing a Probe

Probe and Firmware Compatibility

Check the R2, VC marking on the probe

Check Firmware and Probe Version

Check the manufacturing date on the transmitter head label

Transmitter Head Nut Process Seal Probe

Changing the Probe

Firmware Version Rigid Probes Flexible Probes

Near Zone

GWR Series Near Zone

Troubleshooting Chart

Diagnostic Messages

Symptom Possible cause Action

3for information on possible causes

Surface Pulse Not Found on

Message Description Action

Device Status

Errors are indicated in RRM in the Diagnostics window

Errors

Normally result in Analog Output alarm

RRM, warnings are indicated in the Diagnostics window

Alarms

Measurement Status

Rosemount 5300 Series

Interface Status

Volume Calculation Status

10. Analog Output Status

Analog Output Status

375 Handheld Communicator, or in RRM are shown in Table

For more information on errors, see Errors on

LCD Error Messages

Error Message

Error Message Description

Example

Code Error

Flashing LED

Seconds

Resource Block

Block Errors

13lists conditions reported in the Blockerr parameter

14. Resource Block Summarystatus messages

Analog Input AI Function Block

Power Up

17. Transducer Block Xderr messages

Condition Condition Name and Description

Symptom Possible Causes Recommended Actions

00809-0100-4530, Rev BA July 19. Troubleshooting AI block

Section

Safety Instrumented Systems 4-20 mA only

Rosemount 5300 Series

Applicable Models

Safety Device QS Option

Skill Level of Personnel

Prior-Use Option Model Codes

Damping

Functional Specifications Installation

Minimum input voltage Ui at different currents

Hazardous Current

Operation and Maintenance

Alarm and Saturation Levels

Write Protection Site Acceptance

General

Proof test

Spare Parts Terms and Definitions

References Specifications Failure Rate Data Useful Lifetime

Inspection

Rosemount 5300 Series

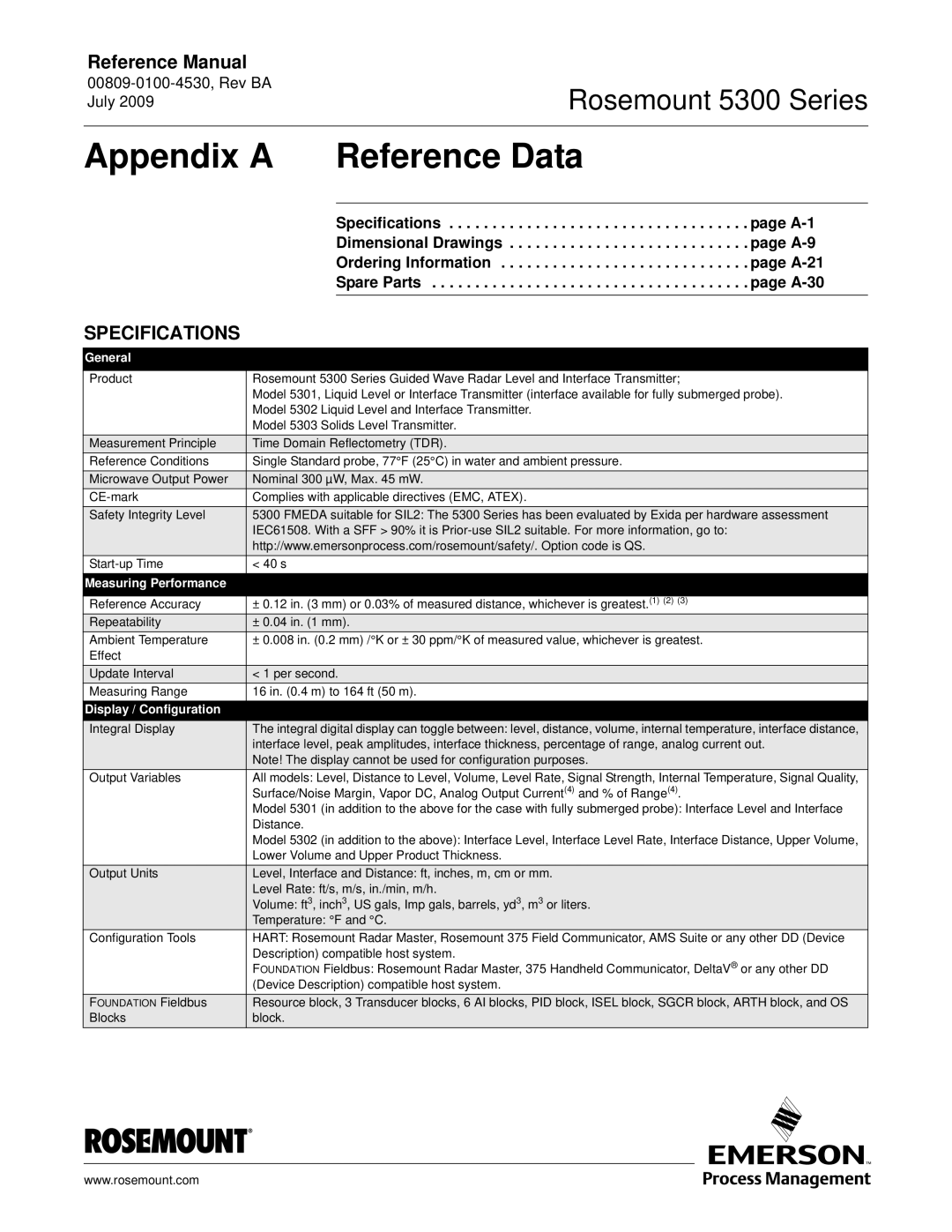

Appendix a Reference Data

Display / Configuration

General

Measuring Performance

Mechanical

Electric

Environment

Pressure psig bar

Process Temperature and Pressure Rating

Temperature F C

Temperature F C

Flange Rating Standards

Flange Connection Rating

JIS

Ambient Temperature

Fisher & Masoneilan

Remote

Remote Housing Measuring Range

Dimensions are in inches millimeters

Dimensional

Drawings

Probe Type 4A, 4B

½ 14 NPT Optional adapters M20x1.5, eurofast and minifast

10.1

NPT 1/1½/2 inch

In. s60

10.1 15.6 In. s52 ½ in. s60

Probe with Flange Connection

Probe Type 5A, 5B

Rosemount 5300 Series

Option W2 140 4 and 6 mm

Figure A-11. Flexible Single Lead with threaded connection

Probe Type 3A, 3B

Figure A-12. Coaxial probe with flange connection

10.1 In. s52 15.6 ½ in. s60

≤ 20 feet 6 m 1½ inch

½ inch

Probe Type 1A

NPT 1½ / 2 inch 10.2 ½ 14 NPT

S60 ≤ 10 feet 3 m 24 6 Ø 0.31 ½ in. s52 In. s60 10.2 Flange

≤ 164 feet 50 m Flange 10.2

Probe Type 2A

Pipe diameter max 2.5 in mm

Figure A-16. Bracket mounting

Figure A-17. Remote housing

Model Code 5301 and 5302 Level and/or Interface in Liquids

Ordering Information

Code Probe Length Units

Code Probe Type Process Connection Probe Lengths

Code Total Probe Length 13 feet/m

Code Total Probe Length 13 in./cm

JIS Flanges15

EN DIN Flanges15

Connections14 Probe Type

Tri-Clamp Fittings14 Probe Type

Code Hazardous Locations Certifications

Special Configuration Software

Code Options

Qx Special Certifications

Remote Housing Mounting

PlantWeb Diagnostic Functionality

Centering Discs Outer Diameter

Consolidate to Chamber

Model Code 5303, Level for Solids

Code Signal Output

Model Product Description

Code Total Probe Length 5 feet/m

EN DIN Flanges7

Flanges6

JIS Flanges7

Connections6 Probe Type

Special Certifications

3.2 ft. Remote Housing Mounting Cable and Bracket

Spare Parts

Spare parts list Transmitter head Model 5301/5302/5303

CSA Fisco Intrinsic Safety2

For other o-ring materials

Spare parts list Probe Model 5301/5302/5303

Code Material of Construction4 Process Probe Type

Code Total Probe Length 12 in./cm

Code Total Probe Length 12 feet/m

Flanges15

EN DIN Flanges13

JIS Flanges13

EN DIN Flanges14

Connections15 Probe Type

Tri-Clamp Fittings15 Probe Type

In. Centering disc21 In. Centering disc PTFE22

Remote Housing / Bracket Mounting

Other accessories

Other spares

Centering discs1

Rosemount 5300 Series

Rosemount 5300 Series

Appendix B Product Certifications

EU Conformity

Special Conditions for Safe Use

Intrinsic Safety

European Atex Directive Information

Rosemount 5300 Series

Rosemount 5300 Series

Flameproof

Rosemount 5300 Series

E3/HART I3/HART

E3/FIELDBUS I3/FIELDBUS

Rosemount 5300 Series

Factory Mutual FM Approvals

Rosemount 5300 Series

Explosion Proof

Dual seal annunciation

Dual seal maintenance

This product meets the Dual Seal Requirements of ANSI/ISA

Rosemount 5300 Series

Explosion Proof

Conditions of Certification

Iecex Approval

Rosemount 5300 Series

Rosemount 5300 Series

Flameproof

Rosemount 5300 Series

Combination Approvals Approval Drawings

Rosemount 5300 Series

Rosemount 5300 Series

Rosemount 5300 Series

Rosemount 5300 Series

Appendix C Advanced Configuration

Rosemount 5300 Series

Distance Offset Tank Height Product Level

Upper Reference Point Transmitter

Handling of Disturbances from Nozzle

Using the Trim Near Zone Function

Trim Near Zone

Trim Near Zone

Click Trim Near Zone

Figure C-3. Trim Near Zone using RRM

Rosemount 5300 Series

Figure C-4. Upper Null Zone

Changing the Upper Null Zone

Interface Threshold

Automatic Surface Threshold

Full Tank Threshold Offset

Reference Threshold

Probe End Threshold

Actual Probe End position Apparent Probe

Probe END Projection

Probe End pulse

Optional configurations

Figure C-10. Echo Tracking

Echo Tracking

Damping

Use Automatic Echo Tracking Settings

Static Vapor Compensation

Dielectric Constant Settings

Lower Product

Vapor Dielectric Constant Lower Product Dielectric

Dielectric constant

Temperature oF/oC Dielectric constant Pressure Pressure Bar

Dynamic Vapor Compensation

Vapor Compensation

VC marking on tank seal

Figure C-14. Single Rigid Hthp with VC marking on the probe

Figure C-15. Minimum requirements

Installation Setup

Click the Calibrate Vapor Compensation button

To calibrate Dynamic Vapor Compensation

Following diagnostics measurements are available

Signal Quality Metrics

Surface Threshold=

Curve ATC

Option and select the Signal Quality Metrics tab

Viewing Signal Quality

Diagnostics Suite

Metrics in RRM

Signal Quality Surface / Noise Margin

Appendix D Remote Mounting

Remote HOUSING, NEW Units

Connect the transmitter head on the housing support

Mount the probe housing on the probe

Remote CONNECTION, Field Retrofit

Remote Housing Configuration

Hart Sequence 2, 6

Appendix E Performing Proof Test

Performing Proof Test Field Communicator

Range 4mA

Enable write protection

Hart Sequence 3, 2, 1, 2

Alarm Mode AOut Loop test

RRM Select Setup, Output from the menu

Rosemount Radar Master RRM

RRM Tools / Echo Curve

Rosemount 5300 Series

AMS Select Device Diagnostics / Tools from the left menu

AMS Click Configure / Setup / Echo Curve

AMS Select Configure / Setup, Analog Output from the menu

AMS Suite

Rosemount 5300 Series

Definition

Appendix F Level Transducer Block

Transmitter

Channel Linearization

Parameters Descriptions

Channel Definitions

Channels for the Rosemount 5300 Series are the following

Table F-1. Channel Assignments

Transducertype

Geomtankheight

Maxupperproductthickness

Table F-3. Probe Type

Table F-5. Environment

00809-0100-4530, Rev BA July Table F-4. Device Mode

Table F-6. Presentation

Table F-7. LCD Parameters

Table F-8. Product Dielectrical Range

Table F-9. Measurement Mode

Unit Codes

Supported Units

Bit Number Value Description Corrective action

Diagnostics Device Errors

Rosemount 5300 Series

Table G-1. Register Access Transducer Block Parameters

Register Access Transducer Block Parameters

Appendix G Register Transducer Block

Parameter Index Description

Parameter Index Description Number

DBREG2FLOAT

Rosemount 5300 Series

Volume measurements

Appendix H Advanced Configuration Transducer Block

Advanced Configuration Transducer Block Parameters

Amplitudethresholdcurve

Volstraptablelength

Rosemount 5300 Series

Definition

Appendix I Resource Transducer Block

Overview Parameters and Descriptions

Cycletype

Maintpri

Saveconfignow

PlantWeb Alerts

Advisory Alarms

Maintenabled

Priority

Alarm Priority

Process Alarms Recommended Actions for PlantWeb Alerts

RB.RECOMMENDEDACTION

Figure J-1. Analog-Input Block

Appendix J Analog-Input Block

Parameter Index Units Description Number

Alarmhys

Device

Simulation

Damping

Figure J-2. Analog Input Function Block Schematic

Signal Conversion

Modes

Block Errors

Table J-2. Blockerr Conditions

Condition Condition Name and Description Number

Priority Number

Alarm Detection

Status Handling

Advanced Features

Configure the AI Block

Table J-5. Level Rate

Table J-8. Volume

Table J-6. Temperature

Table J-7. Signal Strength

Rosemount 5300 Series

Numerics

Index

Ioopts

Varindex

Index-4

Page

Emerson Process Management