30 HP 230/460V

Safety Instructions

Operating Precautions

Page

Page

Page

Contents

Options

Troubleshooting & Maintenance

460V Class 1 ~ 30HP

230V Class 1 ~ 30HP

460V Class 40 ~ 100HP

Common Features Specification

Iii

Page

Environmental Conditions

Inspection

Mounting

075 10 HP 550 75 HP

Installation

Other Precautions

Frame

Dimensions

Blank

Frame # 3 15 ~ 20 HP Frame # 4 25 ~ 30 HP

Blank

230/460 50/60 Hz

Basic Wiring

DC Bus Choke

DB Resistor

Symbols Functions

Power Terminals

Type B Configuration

Installation Type a Configuration

P N B1 B2 U Phase Power Input

N B1 B2

Dynamic Braking Unit Dynamic Braking Resistor DC Bus Choke

Installation Type C Configuration

Shorting terminals may cause internal damage to inverter

Installation Wiring Power Terminals Wiring Precautions

Grounding

Power and Motor Connection B1 B2 U Phase Power Input

Installation Wires and Terminal Lugs

Motor should be connected to the U, V, and W terminals

Control Terminals

Type Symbol Name Description

30A 30C 30B AXA AXC

JOG RST

Control Circuit Terminal

Installation Wiring Control Terminals Wiring Precautions

External Sequence Inverter Circuitry

Keypad Connector

Installation Keypad Connection

Installation

Parameter LCD Keypad Segment Keypad Description Group

Parameter Groups

Operation

LCD Keypad

00 Hz

Operation LCD Keypad Display

Displays Description

Operation Procedure for Setting Data LCD Keypad

Drive Group FU1 Group FU2 Group

Operation Parameter Navigation LCD Keypad

Segment display Encoder knob

7-Segment Keypad

Parameter Group Description

Display Description

Operation 1 7-Segment Keypad Display

First digit

Second digit

FUN2 Group

FUN1 Group

I/O Group

FU1 Group FU2 Group

Operation Parameter Navigation 7-Segment Keypad

Operation Method

Operation Method Function Function Setting

Keypad and Control

Terminals

Operation

Page

QUICK-START Procedures

Quick-Start Procedures

Operation using Keypad

LCD Display Segment Display

LCD Press Prog key Seg PressPROG/ENT key

LCD Display

Operation using Control Terminals

2 W

00 STP 00Hz DRV Drive mode 03 Fx/Rx-1 Keypad DRV Freq mode

Operation using Keypad and Control Terminals

Frequency set by External Source and Run/Stop by Keypad

LCD Press ENT key Seg Press PROG/ENT key

DRV Cmd. freq 00 0.00Hz 00 60.00Hz

00 STP 00Hz

LCD Press ENT key to save the data

SegPress PROG/ENT key to save the data

Page

Basic function parameter setting

Function Setting

Common parameter setting

Parameter Name Code Description

Auto-tuning of motor constant

Function Settings F + PG control

Slip compensation

For V/F, Slip compen , SensorlessS, SensorlessT

Function Settings FU2-40 Description

For VectorSPD, VectorT

Sensorless vector control

Advanced function 1 setting

Function Settings

F control Parameter Name Code Description

Status Code Description

Function Settings Sensorless vector control

Vector control VectorSPD, VectorTRQ

Parameters to view motor and inverter status

Starting / Accel/ Decel / Stopping pattern setting

Protection & fault detection level setting

Speed Signal Applied speed value

Advanced function 2 setting 1 PID operation

Jog and Multi-speed operation

Speed-H Speed-M Speed-L

Energy-saving operation

Function Settings Auto sequence operation

Operation Examples

Wiring

Operation condition

Set it to 0 KeyPad

DRV-5

Operation Example 2nd motor operation

RST AXA

Operation VectorSPD Control Example

Operation Examples

Drive Group DRV

LCD keypad

Parameter List

Function 1 Group FU1

Fwd boost

Limit Hi

Rev boost

Pattern

FU1-99 Return Code Not available

Function 2 Group FU2

Code Description Keypad Display Setting Range Units Factory

Auto tuning

Retry Delay

SS blk time

Pole number

SL I-gain

SL P-gain

PID Ref

PID Out Dir

RPM factor

DB mode

Version

Para. Read

Input/Output Group I/O

P3 define

P2 define

Status

Out status

Segment

Auto mode

Relay mode

Inv No

Baud rate

External Group EXT

P5 define

V2 mode

P6 define

V2 filter

Pulse set

FeedBack

Pulse num

Pulse

LM adjust

LM mode

AM1 mode

AM1 adjust

Communication Group COM

Default

Application Group APP

App Mode

Trv. Scr

Trv. Amp

Trv Off Hi

Trv Off Lo

AutoEx-intv

AutoCh-Mode

Sub-Board Selection Guide According To Function

Parameter List

Page

Monitoring function setting

Digital frequency setting

Setting the DRV-04 Frequency or Torque Mode

Cmd. Freq 00 Hz

10.0

DRV-01 Acceleration Time

Parameter Description DRV

Acc. time

DRV-02 Deceleration Time

DRV-03 Drive Mode Run/Stop Method

20.0

Setting Range Description

Freq mode

Keypad-1

10.00

DRV-05 ~ DRV-07 Step Frequency 1 ~

DRV-08 Output Current

DRV-12 Fault Display

DRV-09 Motor Speed

DRV-10 DC Link Voltage

DRV-13 Motor Direction Set 7-Segment Keypad

DRV-14 Command/Output Frequency Display LCD Keypad

130

DRV-15 Reference/Feedback Frequency Display LCD Keypad

Parameter Description DRV

FU1-03 Run Prevention

FU1-00 Jump to Desired Code #

FU1-05 Acceleration Pattern FU1-06 Deceleration Pattern

FU1 Stop mode Decel

FU1-07 Stop Mode

Parameter description FU1

Decel

FU1 DcBlk time 10 sec

FU1 DcBr freq 00 Hz

FU1 DcBr value 50 %

FU1

FU1 DcSt value 50 %

FU1-14 Pre-excitation Time

FU1 DcSt time Sec

FU1 PreExTime Sec

1000

FU1-15 Hold Time

FU1-16 Pre-excitation Current

00.0

FU1 F-limit Lo

FU1 Freq limit

FU1 F-limit Hi

60.00 Hz

FU1 V/F pattern Linear

FU1-29 Volts/Hz Pattern

15.00

FU1-30 ~ FU1-37 User V/F Frequency and Voltage

100

FU1-38 Output Voltage Adjustment

FU1-39 Energy Save Level

150

FU1 ETH

FU1-54 Overload Warning Level FU1-55 Overload Warning Time

FU1 OL level

FU1 Motor type Self-cool

000

180

990

FU1-99 Return Code 7-Segment Keypad

St bit

Page

Parameter description FU1

FU2-02 Previous Fault History

FU2-01 Previous Fault History

FU2-03 Previous Fault History

FU2-04 Previous Fault History

FU2-10 ~ FU2-16 Frequency Jump

FU2-07 Dwell Frequency FU2-08 Dwell Time

FU2-20 Power on Start Selection

FU2-19 Input/Output Phase Loss Protection Bit Set

FU2-19 Phase Loss Protection Select

0000

FU2-21 Restart After Fault Reset

RST restart

FU2Speed Search

FU2-22 Speed Search Select

FU2 SS blk time Sec

FU2-28 Speed search hold time

FU2Motor select 75kW

75 kW

FU2-38 Carrier Frequency

FU2Control mode

FU2-39 Control mode selection

Control

Detail Tuning Method for Sensorless Vector Control

171

FU2-40 ~ 44 Auto tuning

29.03

FU2 SL P-gain

3276

32767

FU2-47 PID Operation Selection

30.0

300.0

100.0

Parameter Description FU2

Process PID Control

FU2-69 Accel/Decel Change Frequency

FU2-72 Power On Display

FU2-70 Reference Frequency for Accel/Decel

FU2-71 Accel/Decel Time Scale

FU2-73 User display selection

FU2-75 DB Dynamic Braking Resistor Mode Selection

FU2-74 Gain for Motor Speed Display

FU2-76 Duty of DB Dynamic Braking Resistor

FU2-81 ~ FU2-90 2nd Motor Related Functions

FU2-79 Software Version

FU2-91 Parameter Read FU2-92 Parameter Write

Parameter Upload Parameter Download

FU2-94 Parameter Write Protection

FU2-93 Parameter Initialize

FU2-99 Return Code 7-Segment Keypad

Para. init

Parameter Description FU2

06 ~ I/O-10 Analog Current Input I Signal Adjustment

01 ~ I/O-05 Analog Voltage Input V1 Signal Adjustment

Input/Output Group I/O I/O-00 Jump to Desired Code #

Parameter description I/O

20.00

11 Criteria for Analog Input Signal Loss

13 Multi-function Input Terminal ‘P2’ Define

12 Multi-function Input Terminal ‘P1’ Define

14 Multi-function Input Terminal ‘P3’ Define

Speed-L, Speed-M, Speed-H

Parameter Speed-H Speed-M Speed-L

XCEL-L, XCEL-M, XCEL-H

Code

Accel/Decel Parameter XCEL-H XCEL-M

Exchange

Parameter Description I/O Dc-brake

Up, Down

Open-loop

Parameter Description I/O Wire ITerm Clear

Main-drive

Analog hold

Gain2

Xcel stop Hold step

SEQ-L, SEQ-M, SEQ-H

Manual

Segment Keypad Display

LCD Keypad Display

15 Terminal Input Status

16 Terminal Output Status

21 ~ I/O-24 Step Frequency 4, 5, 6

40 FM Frequency Meter Output 41 FM Adjustment

40.00

30.00

43 FDT Bandwidth

42 FDT Frequency Detection Level

44 Multi-function Auxiliary Contact Output

Define AXA-AXC

FDT-2

FDT-1

FDT-3

FDT-4

IOL

FDT-5

Stall

Parameter Description I/O Stop

Lost Command

INV line, Comm line

Ssearch

010

45 Fault Output Relay 30A, 30B, 30C

MMC

9600

46 Inverter Number 47 Baud Rate

Auto B

Parameter Description I/O Auto-A

Parameter Description I/O

Parameter Description I/O

EXT-01 Sub-Board Display

EXT-00 Jump to Desired Code #

Parameter Description EXT

Signal Adjustment Sub-A, Sub-C

EXT-05 V2 Mode Selection Sub-A, Sub-C

EXT-06 ~ EXT-10 Analog Voltage Input

EXT-15 Pulse Input Signal Selection Sub-B

EXT-12 Usage of Pulse Input Signal Sub-B

EXT-13 Real Motor Speed Direction

EXT-14 Encoder Feedback Frequency

EXT-18 ~ EXT-21 Pulse Input Signal Adjustment Sub-B

EXT-17 Filtering Time Constant for Pulse Input Signal Sub-B

EXT-16 Encoder Pulse Number Sub-B

EXT-22 ~ EXT-23 Gains for ‘Sub-B’ Board

EXT-24 Slip Frequency for ‘Sub-B’ Board

EXT-34 LM Load Meter Output Sub-A EXT-35 LM Adjustment

AM1 Adjust

AM1 mode Frequency

AM2 mode DC link Vtg

AM2 Adjust

EXT-50~53 Speed limit for Torque mode operation

Speed limit

Torque Dir

Torque change

Direction

EXT-57 Torque Detection Bandwidth

EXT-56 Torque Detection Level

Parameter

Display Name

Application Group APP APP-00 Jump to desired code #

APP-01 Application Mode Selection

Parameter Description APP

APP Jump code 001

APP-03 Traverse Scramble Amplitude

APP-02 Traverse Amplitude

APP-04 Traverse Accel Time APP-05 Traverse Decel Time

ACti

APP-07 Traverse Offset Lo Setting

APP-06 Traverse Offset Hi Setting

APP-08 Running Auxiliary Motor Number Display

APP-09 Starting Auxiliary Motor Selection

60.0

49.99

APP-21 The Number of Aux. Motors

19.00

APP-25 Wake-Up Level

APP-27 Auto Change Time APP-28 Auto Change Level

APP-26 Auto Change Mode Selection

7200

ACtion

APP-33 Draw Size Setting

APP-32 Draw Mode Selection

APP-29 Inter-Lock Selection

APP-30 Actual Value Display

Draw & Override

Page

Name Description

Option

Option Name Description

Options

SUB-A

Sub-A board

Board configuration

VR V2 5G NC Q1 Q2 Q3 Extg NC P4 P5 P6 LM CM

Options Terminal Configuration

Terminal Description

Parameters of Sub-A Board

BOC

Sub-B Board

AOC BOC A+ A- B+ B- FBA FBB GND GND +5V +5V VCC VCC

Options Terminal Configuration total 14 pins

Parameters of Sub-B Board

Sub-B board with Line Drive type encoder

Sub-B board with Open collector type encoder

+ F

Sub-C Board Isolated

Parameters of Sub-C Board

Q1 Extg NC P4 P5 P6 CM NC GND V2 AM1 AM2 VR GND

AOC BOC

Sub-D Board

Encoder Pulse function

Options Parameters of Sub-D board

Input/Output function

Code Description LCD display

GND

Q1 Q2 Extg NC P4 P5 P6 CM NC V2 VR 5G NC NC

AOC BOC

Device-Net Field bus

Remote cable

Options 3 RS485 Communication

Options Mounting the option boards

Optional Keypads

External options

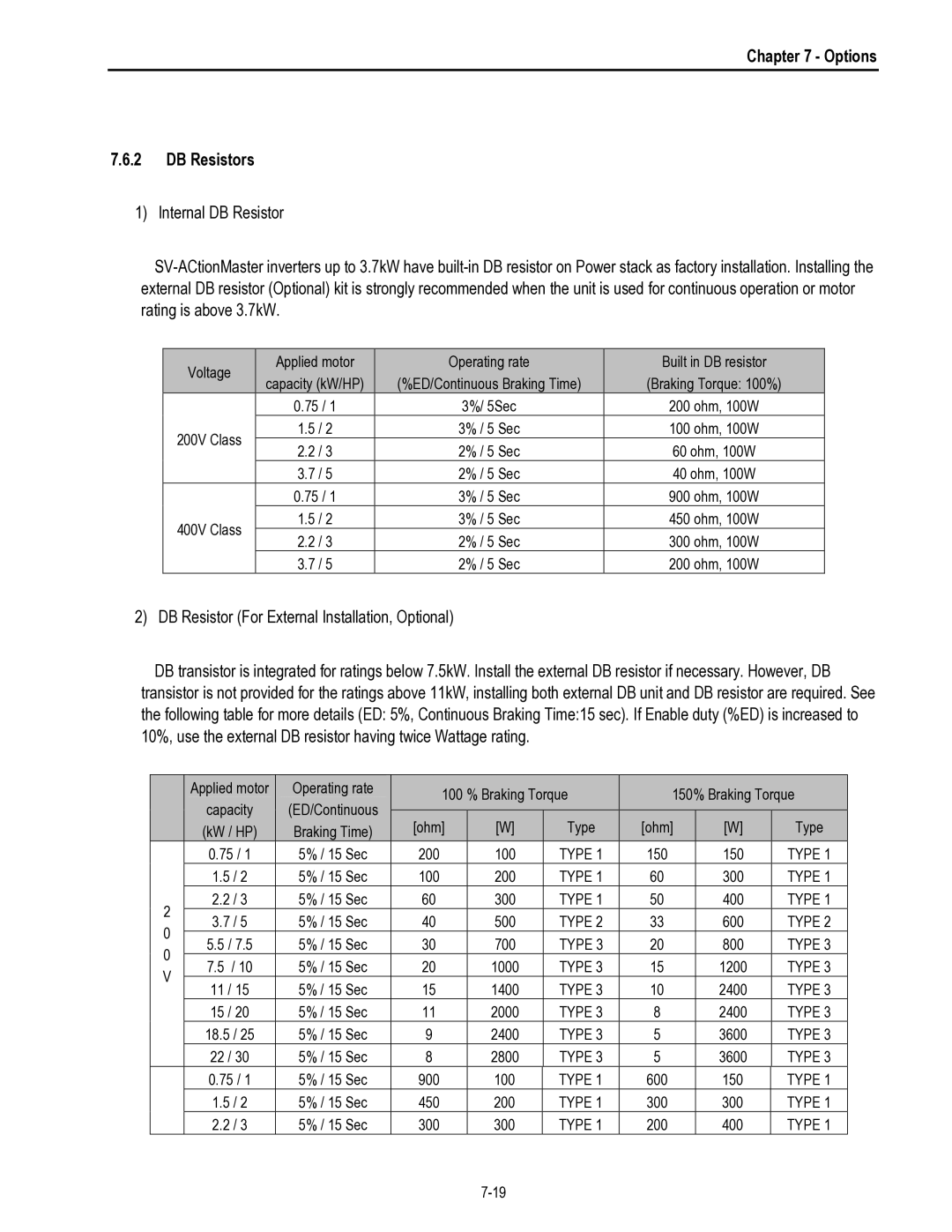

Options DB Resistors

130 600

DB Resistor

RST JOG

B1 B2

DB ResistorDB Unit

Max distance 5m Short Wire should be Twisted

ER-2

BR1000W085J 220 345 140 330

Type 1 Max Watt Type 2 Max Watt

Type

Options DB Dynamic Brake Unit

Inverter Applicable motor rating DB Unit Dimension

CM OH

Dimension

Power LED turns Red when input power is applied to DBU

Suppressing the surge voltage on the inverter output side

Rectifying the motor insulation

Page

Keypad Display Protective Description

Fault Display

Segment Function

OPT

Troubleshooting & Maintenance

Protective Cause Remedy

Fault Remedy

Correctly

Condition Check Point

Troubleshooting

Elements Test Polarity Measured Value

How to Check Power Components

Precautions

Maintenance

Routine Inspection

Periodical Inspection

Megger test

Parts Replacements

Inspection Method Criterion Measuring Instrument

Daily and Periodic Inspection Items

Page

Use Related Parameter Code

Appendix a Functions Based on USE

FU1 Group

Application Parameter Code DRV Group

FU2 Group

Application Parameter Code

Appendix C Peripheral Devices

SMC-50P

Page

EN50178

CD 73/23/EEC and CD 89/336/EEC

EN 50081-2

EN 55011

ENV 50140

EN 50178

ENV 50204

Essential Requirements for CE Compliance

EMC Installation Guide

Viii

Footprint Filters

RFI Filters Footprint Standard for ACtionMaster Series

Dimensions

Revisions

Cleveland Motion Controls