21. MAINTENANCE

21.1 Daily Inspection

Check the residual quantity of chart paper, displaying/printing conditions, etc. on a daily basis in order to use your recorder under good conditions.

1

Consumable parts check

Check items |

|

|

|

| Checking methods | |||||||

|

|

|

|

|

|

|

|

|

|

|

| |

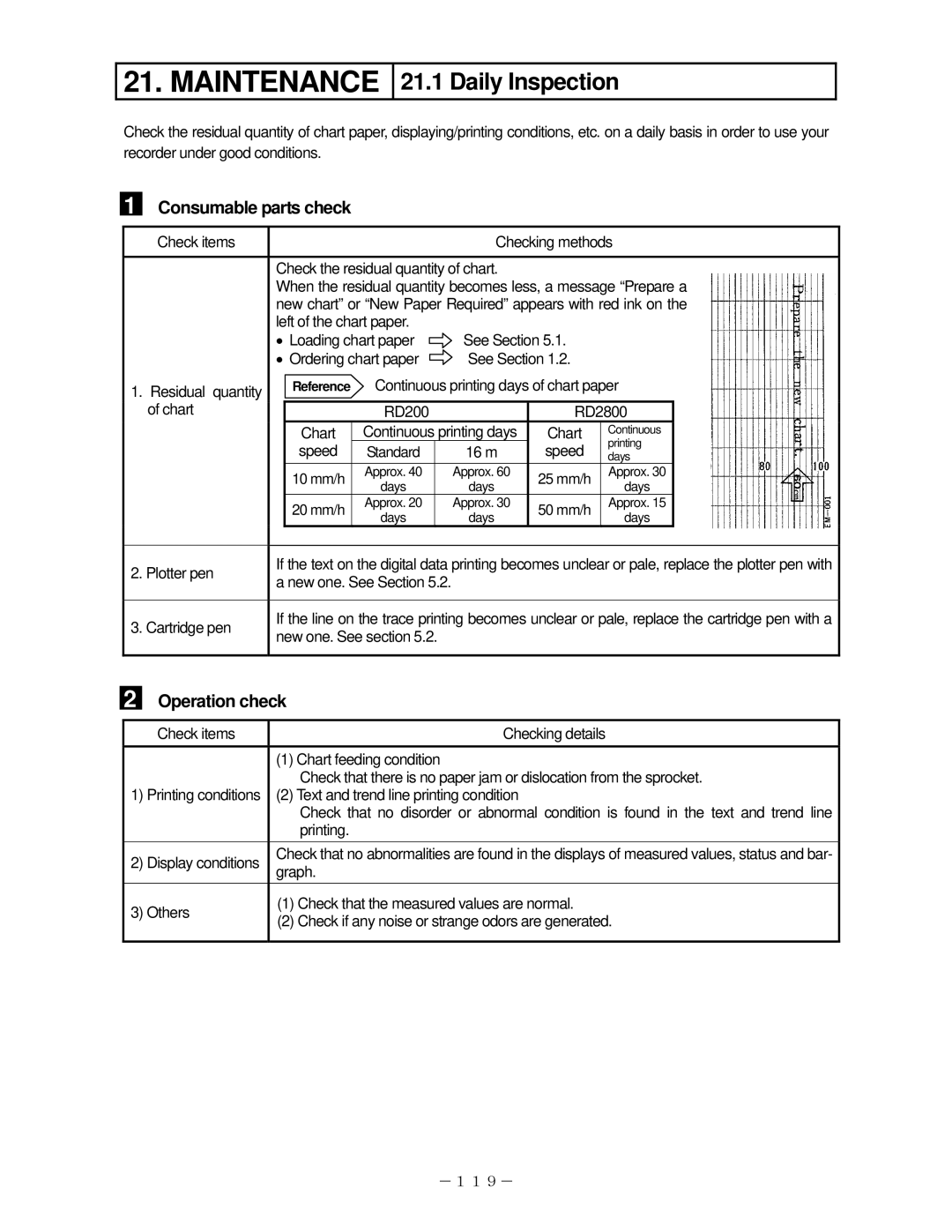

| Check the residual quantity of chart. |

|

|

|

|

|

|

| ||||

| When the residual quantity becomes less, a message “Prepare a |

|

| |||||||||

| new chart” or “New Paper Required” appears with red ink on the |

|

| |||||||||

| left of the chart paper. |

|

|

|

|

|

|

|

| |||

| • Loading chart paper | See Section 5.1. |

|

|

|

| ||||||

| • Ordering chart paper | See Section 1.2. |

|

|

|

| ||||||

1. Residual quantity |

| Reference | Continuous printing days of chart paper |

|

| |||||||

of chart |

|

| RD200 |

|

| RD2800 |

|

|

| |||

|

| Chart | Continuous printing days |

| Chart | Continuous |

|

|

| |||

|

| speed | Standard |

| 16 m |

| speed | printing |

|

|

| |

|

|

|

| days |

|

|

| |||||

|

| 10 mm/h | Approx. 40 |

| Approx. 60 |

| 25 mm/h | Approx. 30 |

|

|

| |

|

| days |

| days |

| days |

|

|

| |||

|

|

|

|

|

|

|

|

|

| |||

|

| 20 mm/h | Approx. 20 |

| Approx. 30 |

| 50 mm/h | Approx. 15 |

|

|

| |

|

| days |

| days |

| days |

|

|

| |||

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

2. Plotter pen | If the text on the digital data printing becomes unclear or pale, replace the plotter pen with | |||||||||||

a new one. See Section 5.2. |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

| ||||

|

|

|

| |||||||||

3. Cartridge pen | If the line on the trace printing becomes unclear or pale, replace the cartridge pen with a | |||||||||||

new one. See section 5.2. |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

2

Operation check

Check items | Checking details | |

|

| |

| (1) Chart feeding condition | |

| Check that there is no paper jam or dislocation from the sprocket. | |

1) Printing conditions | (2) Text and trend line printing condition | |

| Check that no disorder or abnormal condition is found in the text and trend line | |

| printing. | |

2) Display conditions | Check that no abnormalities are found in the displays of measured values, status and bar- | |

graph. | ||

| ||

3) Others | (1) Check that the measured values are normal. | |

(2) Check if any noise or strange odors are generated. | ||

| ||

|

|

-119-