19. HARDWARE CHECK

19.3 Display Check

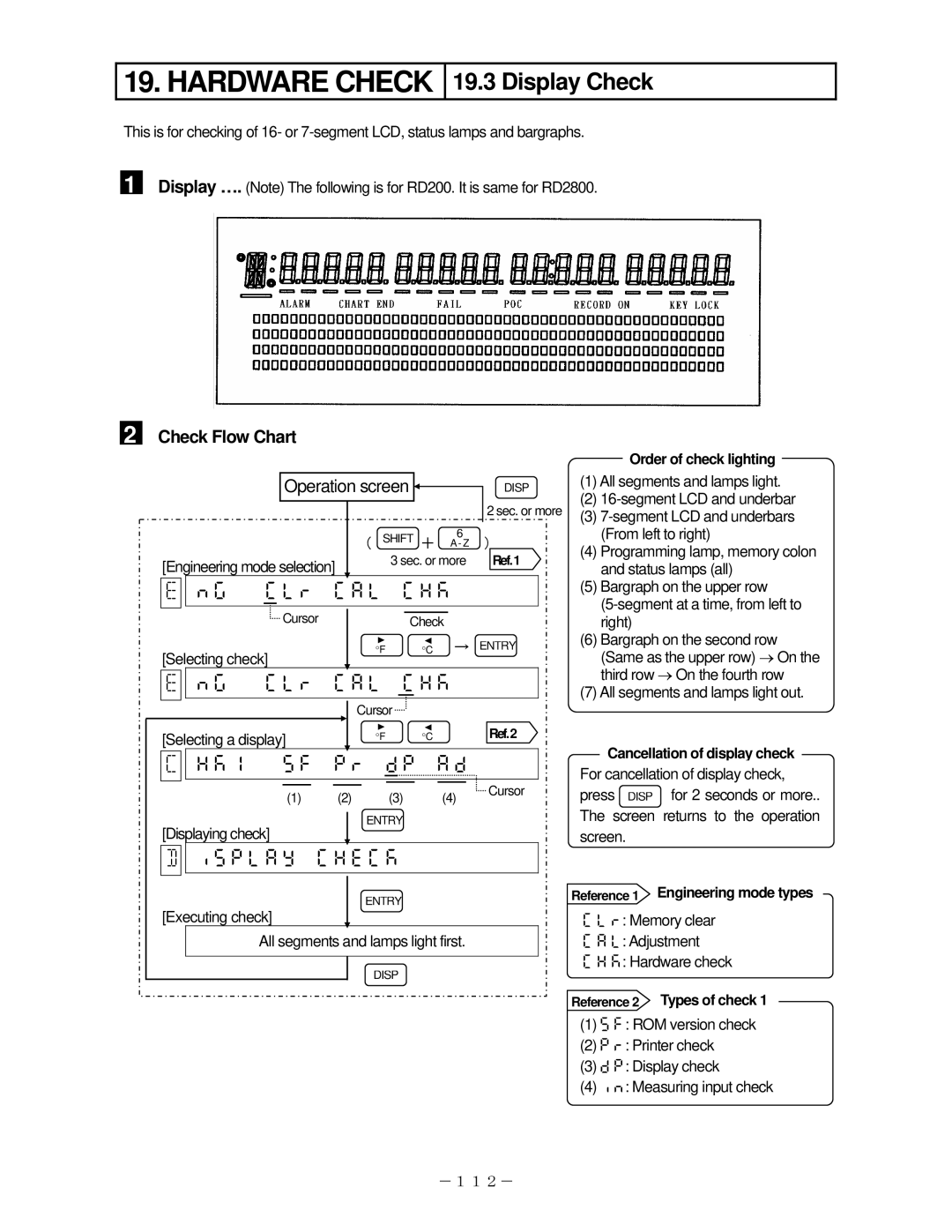

This is for checking of 16- or

1

Display …. (Note) The following is for RD200. It is same for RD2800.

2

Check Flow Chart

Operation screen | DISP |

|

|

2 sec. or more

| ( SHIFT + | 6 | ) |

| A- Z | ||

[Engineering mode selection] | 3 sec. or more | Ref.1 | |

|

|

| |

![]() CursorCheck

CursorCheck

Order of check lighting

(1) All segments and lamps light. |

(2) |

(3) |

(From left to right) |

(4) Programming lamp, memory colon |

and status lamps (all) |

(5) Bargraph on the upper row |

right) |

(6) Bargraph on the second row |

[Selecting check]

°F °C → ENTRY

(Same as the upper row) → On the |

| | |

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Cursor |

|

|

|

| ||

[Selecting a display] |

|

|

| °F | °C | Ref.2 | ||||||

|

|

|

|

|

|

|

|

| ||||

| | |

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Cursor |

|

|

|

|

|

|

|

|

|

|

|

| |

|

| (1) | (2) | (3) | (4) |

| ||||||

|

|

|

| |||||||||

ENTRY

[Displaying check]

ENTRY

[Executing check]

All segments and lamps light first.

DISP

third row → On the fourth row |

(7) All segments and lamps light out. |

Cancellation of display check

For cancellation of display check, press DISP for 2 seconds or more.. The screen returns to the operation screen.

Reference 1 Engineering mode types

: Memory clear

: Adjustment

: Hardware check

Reference 2 Types of check 1

(1): ROM version check

(2): Printer check

(3): Display check

(4): Measuring input check

-112-