18. ADJUSTMENT

18.1 Adjustment of Measured Values

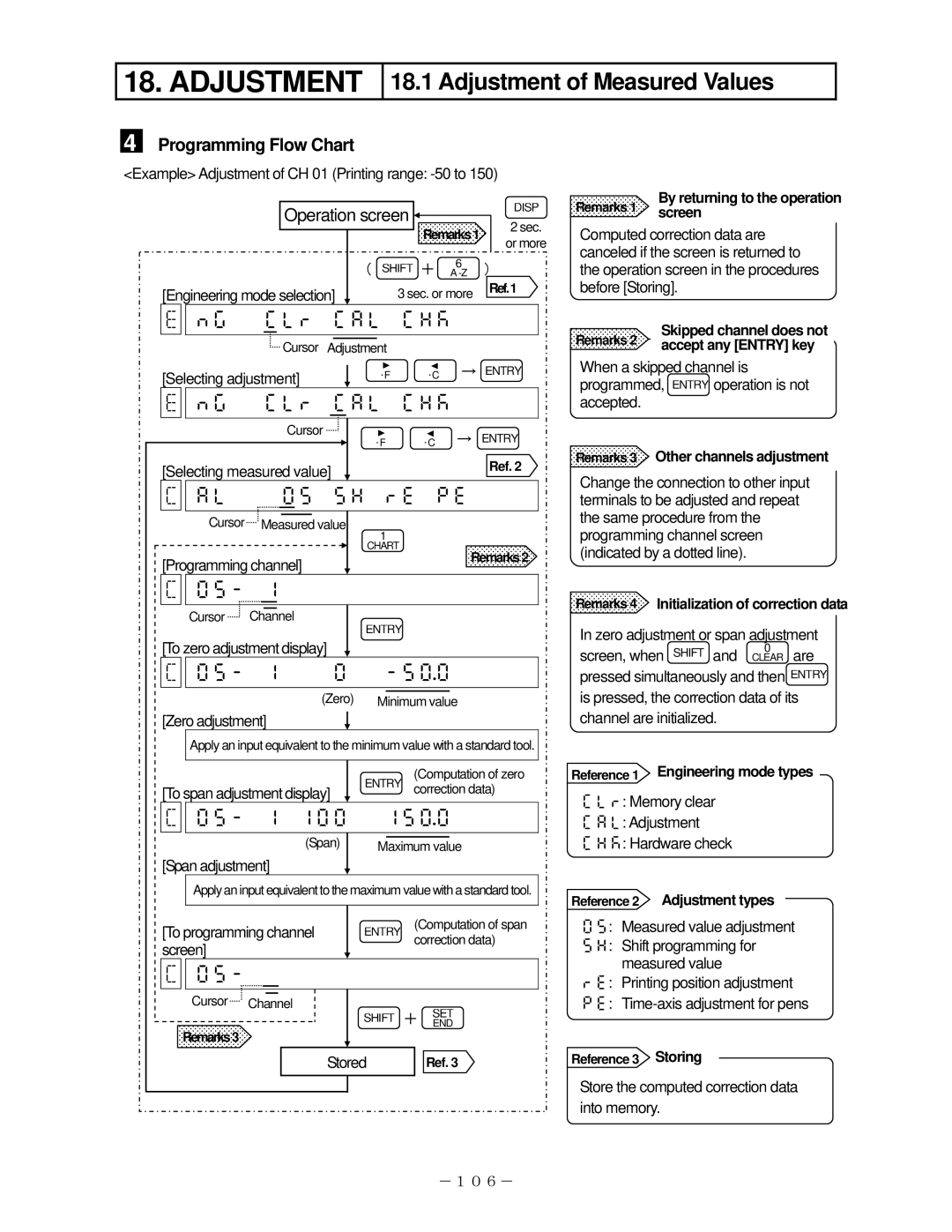

4 Programming Flow Chart

<Example> Adjustment of CH 01 (Printing range:

Operation screen |

| DISP | |

Remarks1 | 2 sec. | ||

| |||

| |||

| or more | ||

|

|

|

|

|

|

|

| ( SHIFT | + | 6 | ) | |

|

|

|

|

|

| |||||

[Engineering mode selection] |

| 3 sec. or more | Ref.1 | |||||||

|

| |||||||||

|

|

|

|

|

|

|

| |||

| |

| ||||||||

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |||

|

|

| Cursor | Adjustment |

|

|

|

| ||

|

|

|

|

|

| ° | ° | → ENTRY | ||

[Selecting adjustment] |

| F | C |

|

| |||||

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| |||

| |

| ||||||||

|

|

| Cursor |

|

|

|

| |||

|

|

| ° | ° | → ENTRY | |||||

|

|

|

|

|

|

| F | C |

|

|

[Selecting measured value] |

|

|

|

| Ref. 2 | |||||

|

|

|

|

|

|

|

| |||

| |

| ||||||||

| Cursor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| Measured value | 1 |

|

|

| |||||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| CHART |

|

|

| |

[Programming channel] | Remarks 2 |

|

Cursor Channel

ENTRY

[To zero adjustment display]

(Zero) Minimum value

[Zero adjustment]

Apply an input equivalent to the minimum value with a standard tool.

|

|

| (Computation of zero | |

[To span adjustment display] | ENTRY correction data) | |||

|

|

|

|

|

| | |||

| (Span) |

|

|

|

|

|

|

| |

|

| Maximum value | ||

[Span adjustment]

Apply an input equivalent to the maximum value with a standard tool.

[To programming channel | ENTRY | (Computation of span |

screen] |

| correction data) |

|

|

Cursor Channel

SHIFT + SETEND

Remarks3

| Stored | Ref. 3 | |

|

|

|

|

|

|

|

|

By returning to the operation Remarks 1 screen

Computed correction data are canceled if the screen is returned to the operation screen in the procedures before [Storing].

|

|

Remarks 2 | Skipped channel does not |

accept any [ENTRY] key |

When a skipped channel is programmed, ENTRY operation is not accepted.

Remarks 3 Other channels adjustment

Change the connection to other input terminals to be adjusted and repeat the same procedure from the programming channel screen (indicated by a dotted line).

Remarks 4 Initialization of correction data

In zero adjustment or span adjustment

0

screen, when SHIFT and CLEAR are pressed simultaneously and then ENTRY is pressed, the correction data of its channel are initialized.

Reference 1 Engineering mode types

: Memory clear

: Adjustment

: Hardware check

Reference 2 Adjustment types

: Measured value adjustment

: Shift programming for measured value

: Printing position adjustment

:

Reference 3 Storing

Store the computed correction data into memory.

-106-