Section 4. Electric Checks and Adjustments

4.5b Print Position Adjustment

Using the VR1 potentiometer on the main PCB board. | VR1 adjustment range is | |

STEP | PROCEDURE | +/- 3.75mm. |

| ||

Refer to Section 4.2 for access to main PCB

1.Record all current dip switch positions, then place all switches in the OFF position and the power switch OFF.

2.Turn VR1 on the main PC Board to the center position.

3.Place

4.Press the LINE and FEED key while simultaneously turning the power switch ON.

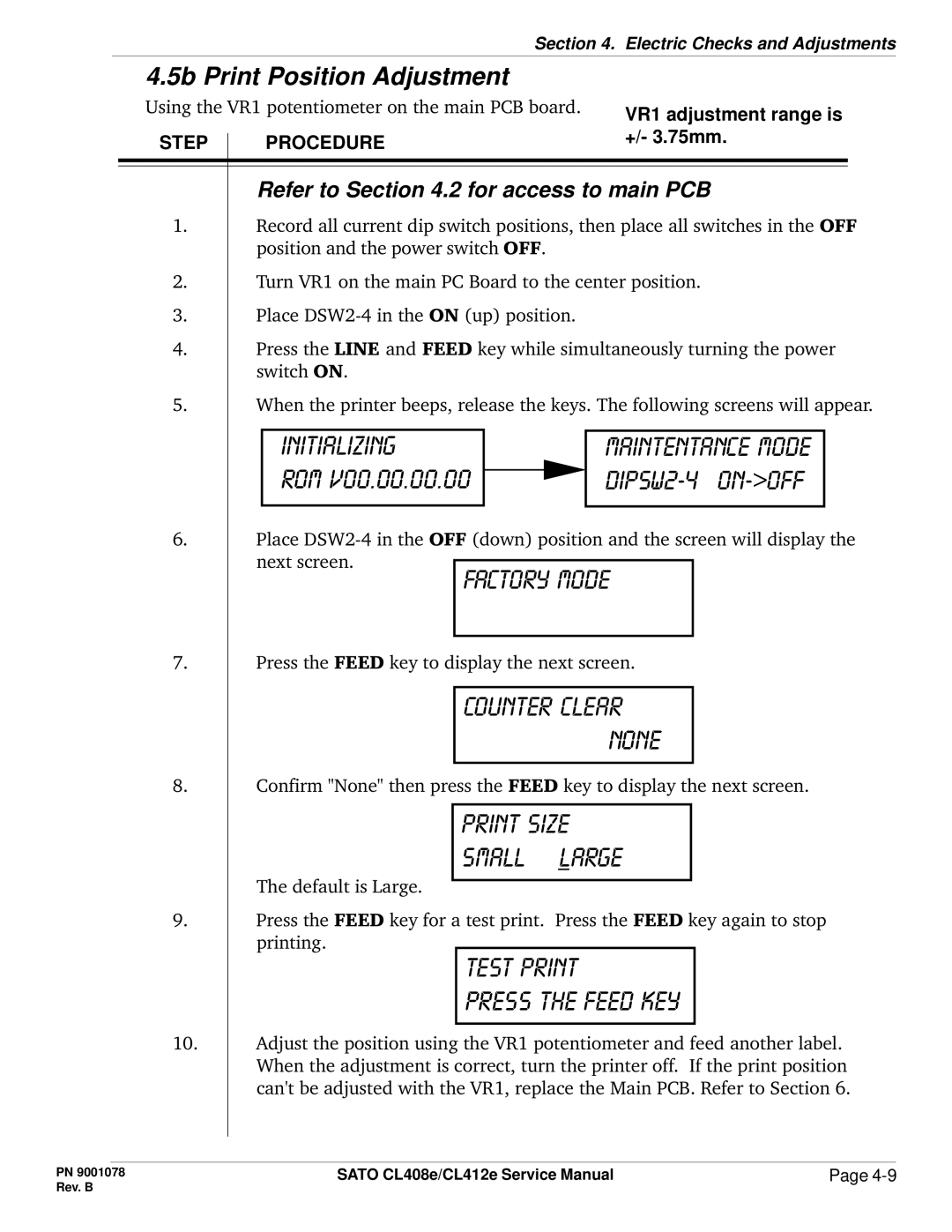

5.When the printer beeps, release the keys. The following screens will appear.

initializing |

| maintentance mode |

rom v00.00.00.00 |

|

|

| ||

|

|

|

6.Place

next screen.

factory mode

7.Press the FEED key to display the next screen.

counter clear none

8.Confirm "None" then press the FEED key to display the next screen.

print size small large

The default is Large.

9.Press the FEED key for a test print. Press the FEED key again to stop printing.

test print

press the feed key

10.Adjust the position using the VR1 potentiometer and feed another label. When the adjustment is correct, turn the printer off. If the print position can't be adjusted with the VR1, replace the Main PCB. Refer to Section 6.

PN 9001078 | SATO CL408e/CL412e Service Manual | Page |

Rev. B |

|

|