Section 5. Mechanical Adjustments

5.6 Print Head Balance Adjustment

Required Equipment: | • | 10mm Open End Wrench |

| • | #2 Pozidrv Screwdriver |

|

|

|

To optimize print quality, perform the following steps to adjust the Print Head Balance using head pattern as a guide. Proper adjustment is necessary to avoid ribbon wrinkle.

STEP PROCEDURE

1.Load the ribbon and label stock into the printer.

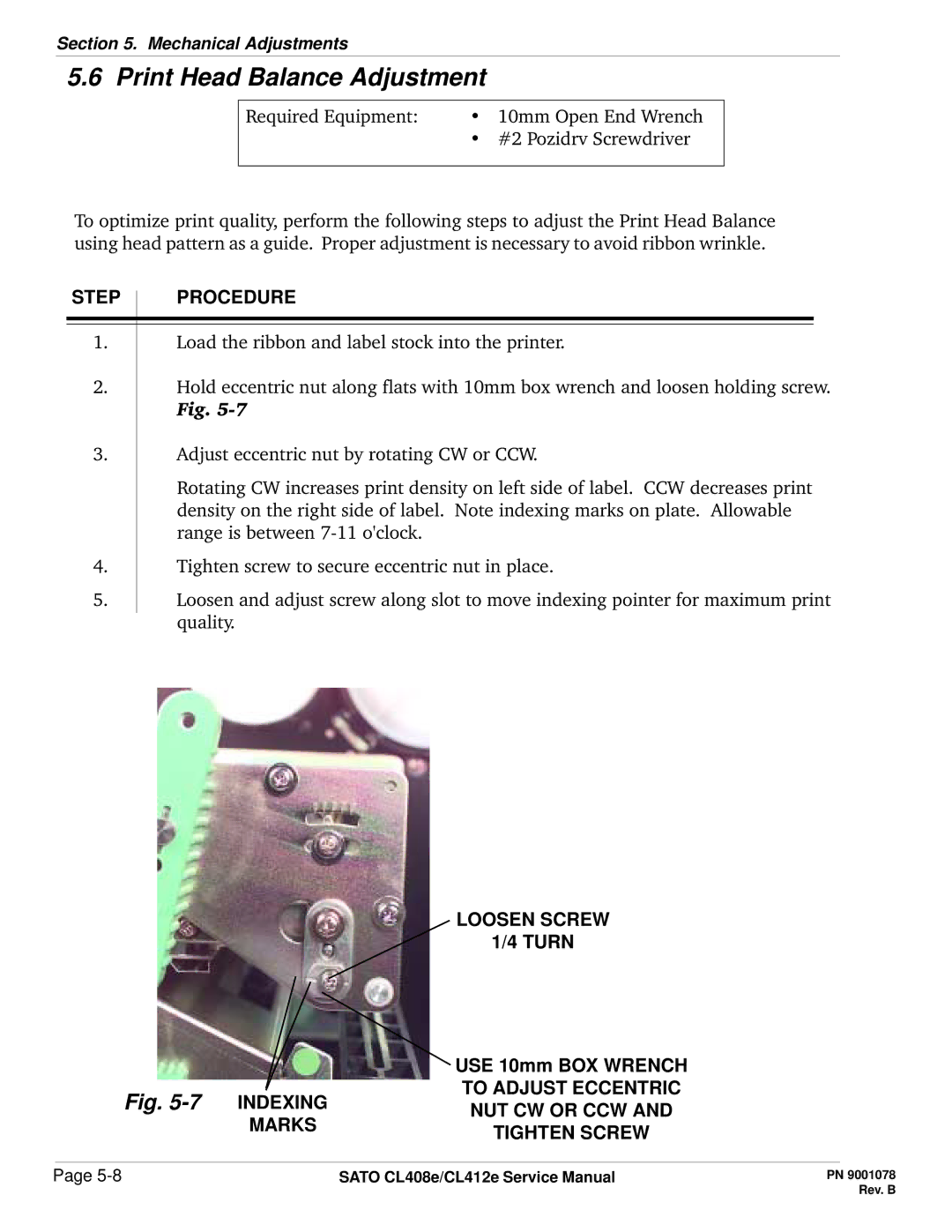

2.Hold eccentric nut along flats with 10mm box wrench and loosen holding screw. Fig.

3.Adjust eccentric nut by rotating CW or CCW.

Rotating CW increases print density on left side of label. CCW decreases print density on the right side of label. Note indexing marks on plate. Allowable range is between

4.Tighten screw to secure eccentric nut in place.

5.Loosen and adjust screw along slot to move indexing pointer for maximum print quality.

LOOSEN SCREW

1/4 TURN

|

| USE 10mm BOX WRENCH | |

Fig. | INDEXING | TO ADJUST ECCENTRIC | |

NUT CW OR CCW AND | |||

| MARKS | ||

| TIGHTEN SCREW | ||

|

|

Page | SATO CL408e/CL412e Service Manual |