Commissioning (software)

4.6 Using

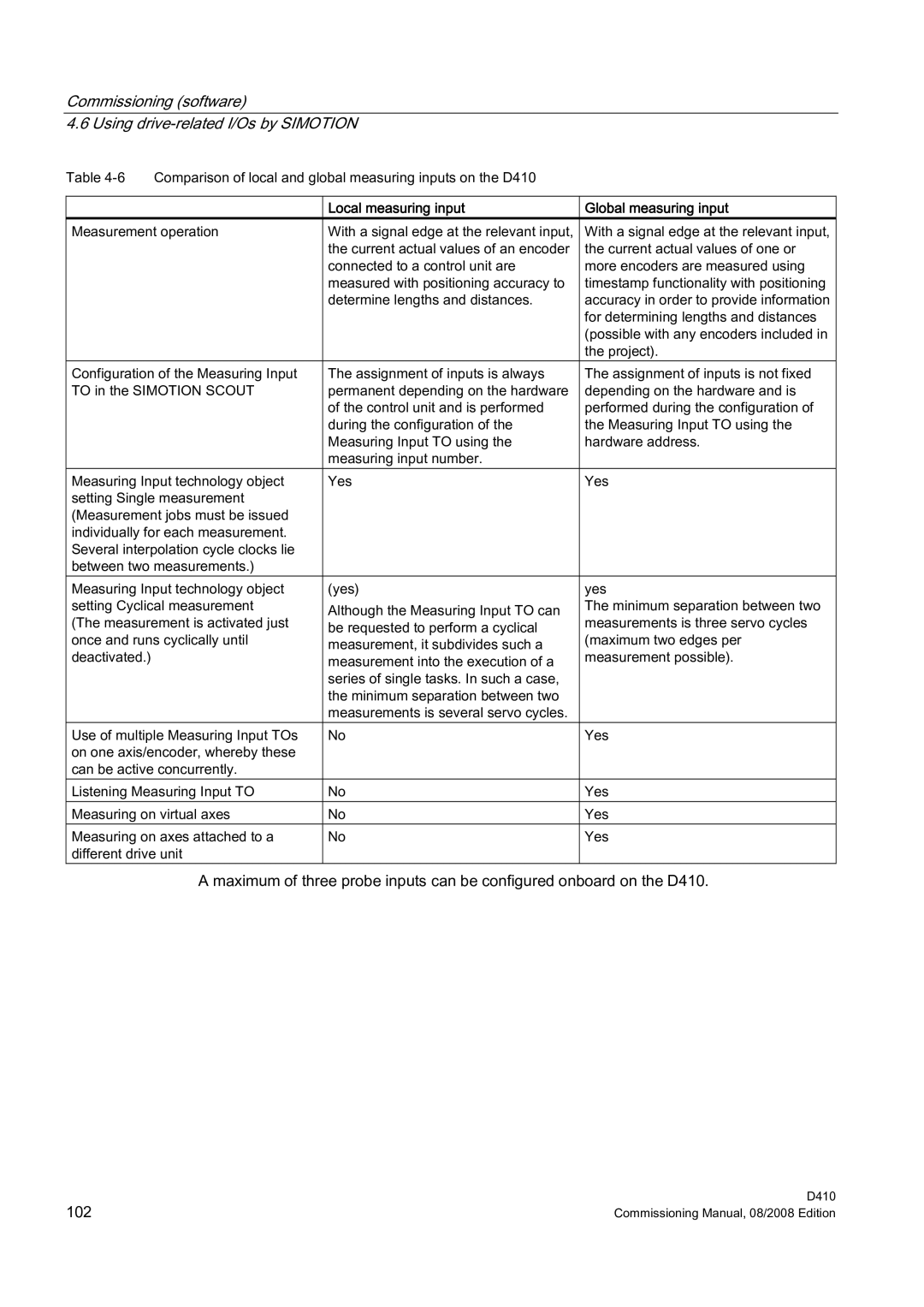

Table | Comparison of local and global measuring inputs on the D410 |

| |

|

|

|

|

|

| Local measuring input | Global measuring input |

Measurement operation | With a signal edge at the relevant input, | With a signal edge at the relevant input, | |

|

| the current actual values of an encoder | the current actual values of one or |

|

| connected to a control unit are | more encoders are measured using |

|

| measured with positioning accuracy to | timestamp functionality with positioning |

|

| determine lengths and distances. | accuracy in order to provide information |

|

|

| for determining lengths and distances |

|

|

| (possible with any encoders included in |

|

|

| the project). |

Configuration of the Measuring Input | The assignment of inputs is always | The assignment of inputs is not fixed | |

TO in the SIMOTION SCOUT | permanent depending on the hardware | depending on the hardware and is | |

|

| of the control unit and is performed | performed during the configuration of |

|

| during the configuration of the | the Measuring Input TO using the |

|

| Measuring Input TO using the | hardware address. |

|

| measuring input number. |

|

Measuring Input technology object | Yes | Yes | |

setting Single measurement |

|

| |

(Measurement jobs must be issued |

|

| |

individually for each measurement. |

|

| |

Several interpolation cycle clocks lie |

|

| |

between two measurements.) |

|

| |

Measuring Input technology object | (yes) | yes | |

setting Cyclical measurement | Although the Measuring Input TO can | The minimum separation between two | |

(The measurement is activated just | be requested to perform a cyclical | measurements is three servo cycles | |

once and runs cyclically until | measurement, it subdivides such a | (maximum two edges per | |

deactivated.) |

| measurement into the execution of a | measurement possible). |

|

| series of single tasks. In such a case, |

|

|

| the minimum separation between two |

|

|

| measurements is several servo cycles. |

|

Use of multiple Measuring Input TOs | No | Yes | |

on one axis/encoder, whereby these |

|

| |

can be active concurrently. |

|

| |

Listening Measuring Input TO | No | Yes | |

Measuring on virtual axes | No | Yes | |

Measuring on axes attached to a | No | Yes | |

different drive unit |

|

| |

A maximum of three probe inputs can be configured onboard on the D410.

102 | D410 |

Commissioning Manual, 08/2008 Edition |