J2-Super Series

Safety Instructions

To prevent electric shock, note the following

HC-UFS

HC-SFS81

HC-SFS121

HC-SFS202

COM

Wiring

RA EM1 24VDC

Usage

Dispose of the product as general industrial waste

Maintenance, inspection and parts replacement

EMC directive

Configuration

Low voltage directive

Machine directive

Power supply

Wiring

Grounding

Performing EMC tests

Auxiliary equipment and options

Also read the manual of the servo system controller

Use UL/C-UL standard-compliant products

Contents Functions and Configuration

To 8

To 7

To 9

10- 1 to 10

11.2

11.1

11.3

11.4

Page

Functions and Configuration

Functions and Configuration

Introduction

Function block diagram of this servo is shown below

Function block diagram

Servo amplifier standard specifications

Function list

High-resolution encoder

Absolute position detection

Chapter

Model code definition Rating plate

Phase 200 to 230VAC

Model

100 1000 200 2000 400 350 3500 600 5000 700 7000

Combination with servo motor

Battery holder

Structure Parts identification MR-J2S-100B or less

Ground terminal

MR-J2S-200B MR-J2S-350B

MR-J2S-500B

MR-J2S-700B

Name plate Main circuit terminal block TE1

Brake option and servo motor

For MR-J2S-500B

For MR-J2S-700B

For 3-phase 200V to 230VAC or 1-phase 230VAC

MRZJW3-SETUP121E

CN1A

Servo configuration software Section

For 1-phase 100V to 120VAC

No-fuse breaker Section Regenerative brake option

Magnetic contactor Section Cables

SETUP121E

Cables Section Servo configuration software

No-fuse breaker

Regenerative brake option Section Magnetic contactor

FA-BAL

Options and auxiliary equipment Refer to

Memo

Installation

Installation

Control box

Installation of two or more servo amplifiers

Others

Keep out foreign materials

Cable stress

Signals and Wiring

Signals and Wiring

Connection example of control signal system

MR-J2HBUS M-A MR-HBUS M

Signal arrangement

I/O signals Connectors and signal arrangements

Input signal

Output signals

Power supply

Instantaneous power failure

Regenerative alarm

Overcurrent, overload 1 or overload

OFF

24VDC MBR

Interfaces 3.4.1 Common line

Detailed description of the interfaces

Give a signal with a relay or open collector transistor

Digital input interface DI-1

Digital output interface DO-1

Encoder pulse output DO-2

Lamp load

Output pulse

LAR LBR, LZR

Analog output

Output voltage 10V Max. output current 1mA Resolution 10bit

RA1 RA2

For 3-phase 200 to 230VAC power supply

Not provided for 1-phase 100 to 120VAC

For 1-phase 100 to 120VAC or 1-phase 230VAC power supply

50/60Hz Phase 100 to 120VAC

11, L Control circuit power supply Phase 200 to 230VAC

Terminals

Refer to Sections 12.1.2 and 12.1.3 for details

Power-on sequence Power-on procedure

Timing chart

VDD COM EM1

Connection diagram

HC-MFS053 B to 73 B

HC-KFS053 B to 73 B

HC-UFS13 B to 73 B

HC-SFS121 B to 301 B

3 I/O terminals HC-KFS HC-MFS HC-UFS3000r/min series

Black

White

Earth

HC-SFS HC-RFS HC-UFS2000 r/min series

COM 24VDC MBR

Setting

Coasting Servo motor speed Min 60ms Base circuit

Both main and control circuit power supplies off

Alarm occurrence

Power supply Phase

Approx mm

Connection

Instructions for the 3M connector

Axis

Control axis selection

Memo

Operation and Display

Operation and Display

Before starting operation, check the following

Parameter setting

Power on

Servo-on

Home position return

Stop

Display sequence

Servo amplifier display

Indication list

Test operation mode

Operation method

100000

Motorless operation

Operation procedure

Parameters

Parameters

Instable

Parameter write inhibit

Item list

Column

Details list

FR-RC FR-BU

Point

Basic

CCW

15Hz Response 20Hz 25Hz 30Hz 35Hz 45Hz 55Hz Middle 70Hz

Result of auto tuning

85Hz 105Hz

130Hz 160Hz 200Hz High 240Hz Basic Response 300Hz

Refer to Section Function Column

Speed loop gain 177 Rad/s

40dB 14dB 8dB

4dB

Pulse unit parameter No

8V/max. current command

Servo motor speed 8V/max. speed

Max. speed Droop pulses

For manufacturer setting Must not be changed

Used to set the output range of the zero speed signal ZSP

For manufacturer setting 0001 Must not be changed

Used to set the output range of the error excessive alarm

Pulse setting Function Column

Maximum output frequency is 1.3Mpps after multiplication by

Encoder output pulses 4000

Parameters Set value Output pulse

0000 Refer to

Change the following digits of parameter No.22

Setting description

PWM

Analog monitor block diagram

Main modifications made to the parameters

Replacement of MR-J2- B by MR-J2S- B

Auto tuning parameter No

Servo response parameter No

High 130Hz Response

Machine resonance suppression filter 1 parameter No

Error excessive alarm level parameter No

In-position range parameter No

Analog monitor output parameter No

Encoder output pulse parameter No

Optional function 6 parameter No

Memo

General Gain Adjustment

General Gain Adjustment

Gain adjustment mode explanation

Start

Adjustment sequence and mode usage

OK?

END

You can automatically set the optimum gains

Adjustment using servo configuration software

Time

Gain search Executing gain search under to-and-fro

Conditions are not satisfied

Auto tuning Auto tuning mode

Ratio of load inertia moment to servo motor inertia moment

Position control gain

Block diagram of real-time auto tuning is shown below

Auto tuning mode operation

PG1,VG1

PG2,VG2,VIC

Basic procedure

Adjustment procedure by auto tuning

15Hz 20Hz 25Hz 30Hz

Response level setting in auto tuning mode

35Hz 45Hz

55Hz Middle 70Hz

Operation of manual mode

Manual mode 1 simple manual adjustment

Adjustment by manual mode

Adjustment procedure

For position control

Suppression of machine resonance

Refer to .2

General Gain Adjustment

Adjustment procedure

Interpolation mode

Adjustment description

Parameter

Auto tuning selection

15Hz

100Hz 105Hz 130Hz 160Hz 200Hz 240Hz 300Hz

Special Adjustment Functions

Special Adjustment Functions

Machine resonance suppression filter Function

Deep 40dB 14dB 8dB Shallow 4dB

Parameter No Notch frequency selection

Adaptive vibration suppression control Function

Set the operation of the low-pass filter parameter No.25

Low-pass filter Function

Inspection

Inspection

Inspection

Life

Memo

Troubleshooting

Troubleshooting

Alarms and warning list

Alarms

B160V or Control power failure of 60ms or Less Longer

B183V or

Change the servo amplifier

Error Occurred at Output wires are in contact at

Alarm 17 or 19 occurs if power

Super capacitor of the absolute

Reduce the frequency of positioning

Constant

Alarm 32 occurs if power is Switched on after U,V and W

Reexamine acceleration

Deceleration time constant

Parameter error Parameter setting is

Overload

Remedies for warnings

Memo

Outline Dimension Drawings

Outline Dimension Drawings

TE1 TE2

TE1

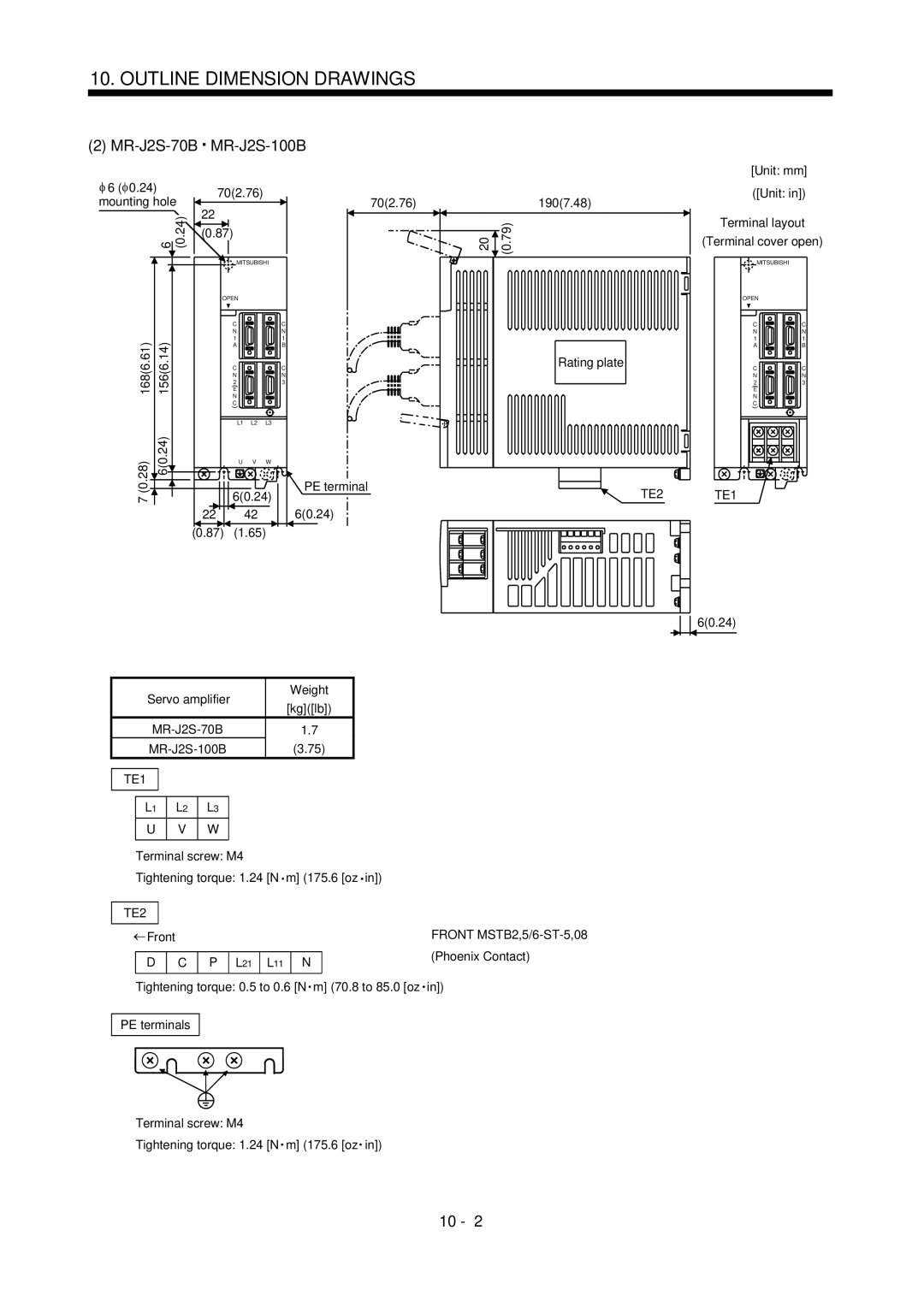

MR-J2S-70B MR-J2S-100B

MR-J2S-200B MR-J2S-350B

MR-J2S-500B

Mounting hole 1807.09 2007.87 1606.23 1385.43 60.24

Insulation displacement type

Connectors Servo amplifier side 3M

Soldered type

Threaded type

PCR-LS20LA1

Bus cable connector Honda Tsushin Industry

PCR-LS20LA1W

DE-C1-J6-S6 34.51.36 190.75 24.990.98 331.30 60.24

Memo

Characteristics

Characteristics

Overload protection characteristics

Electronic thermal relay protection characteristics

MR-J2S-500B MR-J2S-700B

MR-J2S-20B1

MR-J2S-10B1

MR-J2S-40B1

MR-J2S-60B

Heat dissipation area for enclosed servo amplifier

Temperature distribution in enclosure

There is internal relay delay time of about 30ms

Dynamic brake characteristics

Mmin

Mm/minin/min

HC-SFS1000r/min series

HC-KFS series

HC-SFS3000r/min series

HC-MFS series

Encoder cable flexing life

MR-JCCBL M-H MR-JHSCBL M-H MR-ENCBL M-H

MR-JCCBL M-L MR-JHSCBL M-L

Memo

Options and Auxiliary Equipment

Options and Auxiliary Equipment

Selection of the regenerative brake option

104

JM No 1047

No T2 t1

No regeneration

FR-RC FR-RB

Set parameter No.2 according to the option to be used

Connection of the regenerative brake option

Mounting method

For the MR-RB51 install the cooling fan as shown

MR-RB032 MR-RB12

Outline drawing

MR-RB32

MR-RB50

Selection

Brake unit

FR-BU-15K

16.5 MR-J2S-500B FR-BU-30K

Outside dimensions

Brake unit FR-BU

Unit mmin

Resistor unit FR-BR

Power return converter Selection

RDY

NFB MC FR-BAL VDD COM ALM

FR-RC

RA2 EM1 OFF

Mounting hole machining dimensions

Outside dimensions of the power return converters Unit mmin

CN1A CN1B

Cables and connectors Cable make-up

CN2 CN3

HC-KFS HC-MFS

Encoder cable Refer to 2 in this Life Section IP20

Long flexing

IP67

Not oil

Manual Power supply

Connector Maintenance

Manual IP65 IP67 Power supply

Manual Brake connector

Standard flexing life Long flexing life

Servo amplifier side Encoder side

MR-JHSCBL M-L

MR-JHSCBL10M-H

Communication cable

Connection diagram

Model MR-CPCATCBL3M

MR-CPCATCBL3M

Cause misoperation or explosion

Bus cable

ModelMR-J2HBUS M-A

ModelMR-J2HBUS M

Maintenance junction card MR-J2CN3TM Usage

MR-J2HBUS CN3B CN3A CN3C

CN3A CN3B CN3C MO1 MO2 VDD COM EM1 MBR Emgo

Battery MR-BAT, A6BAT

Specifications

Servo configurations software

System configuration

Configuration diagram

Recommended wires

Recommended wires Wires for power supply wiring

Auxiliary equipment

5mm2 for use of the HC-RFS203 servo motor

Wires for cables

Wires for option cables

Recommended crimping terminals

No-fuse breakers, fuses, magnetic contactors

Power factor improving reactors

Following relays should be used with the interfaces

Relays

Surge absorbers

Noise reduction techniques

Options and Auxiliary Equipment

10 to 100MHZ 100 to 500MHZ 150

Noise reduction products

Ex A.2003

Outline drawing

On the output side, the number of turns must be four or less

Leakage current breaker Selection method

Selection example

Combination with the servo amplifier

EMC filter

SF1252

MR-J2S-200B MR-J2S-350B SF1253

HF3040-TM HF-3050A-TM

Features

Position setting again. Not doing so can cause runaway

Absolute Position Detection System

Absolute Position Detection System

CN1 CN2

Specifications Specification list

CON1

Confirmation of absolute position detection data

Manual number is given on the bottom left of the back cover

Revisions

Sep SHNA030007-A

SHNA030007-B