SR5 0

This section is specifically about safety matters

Conditions, resulting in death or severe injury

Cause physical damage only

Page

Page

Page

Multi-speed setting RL, RM, RH, REX signals Setting 0, 1, 2

How to Use the Input Signals

Frequency jump

Handling of the RS-485 Connector

Biases and gains of the frequency setting voltage current

Stall prevention

Retry function PWM carrier frequency Applied motor

Restart setting

Operation mode selection PID control 101

Monitoring reference

Correspondence between digital and actual characters 145

To know the operating status at the occurrence of alarm

137

145

Abbreviations

Wiring

Terminal connection diagram

Japanese Version

FR-S520-0.1K to 3.7K -R -C FR-S540-0.4K to 3.7K -R

Layout and wiring of main circuit terminals

FR-S520S-0.1K to 1.5K -R -C FR-S510W-0.1K to 0.75K -R

NFB MC

North America Version

Inverter

FR-S520-0.1K to 3.7K-NA FR-S540-0.4K to 3.7K-NA R

FR-S510W-0.1K, 0.2K, 0.4K-NA FR-S510W-0.75K-NA

Reduce the output current

FR-S540-0.4K to 3.7K-ECR

European Version

FR-S520S-0.2K to 1.5K-EC R

FR-S540-0.4K, 0.75K, 1.5K, 2.2K, 3.7K-EC R

FR-S520S-0.2K, 0.4K, 0.75K-EC R FR-S520S-1.5K-EC R

Terminal names in parentheses are those of the EC version

Description of I/O Terminal Specifications

Main circuit

Control circuit

RUN

FR-S510W-0.1K to 0.75K -R FR-S510W-0.1K to 0.75K-NA

How to Use the Main Circuit Terminals

Cables, wiring lengths, crimping terminals, etc

FR-S520S-0.1K to 1.5K -R FR-S520S-0.2K to 1.5K-EC R

Wiring instructions

Selection of peripheral devices

Peripheral devices

AC Reactor DC Reactor Model

L1, N

Cables mm2

Line-to-line leakage currents

To-ground leakage currents

∆ n ≥ 10 ⋅ lg1+Ign+lg2+lgm

During commercial power

Type SP, CF, SF, CP

Rated sensitivity current

STF STR

Power-off and magnetic contactor MC

Inverters primary side magnetic contactor MC

OFF

NFB FR-BAL

Regarding noise and the installation of a noise filter

BIF

Grounding precautions

Noise reduction examples

BLF

Japanese power harmonic suppression guideline

Regarding power harmonics

Received Power Voltage 5th 7th 11th 13th 17th 19th 23rd Over

Conversion Factors for FR-S500 Series

No reactor, 100% operation ratio

Harmonic suppression technique requirement

Harmonic suppression techniques

Rated 6kV

How to Use the Control Circuit Terminals

Terminal block layout

M3 A, B, C terminals Al 0.5-6WH

Input signals are set to sink

Using tweezers, a pair of long

Changing the control logic

RUN 24VDC

STR

STR R

Right The forward/reverse rotation signal is

Input Terminals

Run start and stop STF, STR, Stop

Three-wire type connection STF, STR, Stop

STR-SD

STF-SD

Basic

Voltage input 10, 2

AU-SD on OFF

Manual-Automatic Switching

External frequency selection REX, RH, RM, RL

Current input 4, 5, AU

REX

External command

Japanese version FM

Indicator connection and adjustment

Output waveform of terminal FM

CPU

NA and EC version AM

Control circuit common terminals SD, 5, SE

Signal inputs by contactless switches

Second function selection RT signal Setting

Current input selection AU signal Setting

Start self-holding selection Stop signal Setting

External thermal relay input Setting

Output shut-off MRS signal Setting

Jog operation JOG signal Setting

Reset signal Setting

Jog operation using external signals

Use the optional FR-CB2

PID control valid terminal Setting

PU operation/external operation switching Setting

When connecting the parameter unit

System configuration examples

RS-485 communication

4P Twisted pair cable, 4 pairs

Wiring of one RS-485 computer and one inverter

Wiring methods

MC1

Design Information

Communication Parameters Only for the Type

Functions

Function Parameter List

Func- Pa- Indica- tion rame- tion ter

Minimum Factory Cus Name Setting Range

Minimum Factory Refer Cus Name Setting Range

FM AM

THM, THT, GF

OHT, OLT, PE, OPT

PWM

Selection functions

PID

ECL

Alarm history 115 Clear

Func Tion

Cation

NA, EC

Com Minimum

For details of the program, refer to page 118 onwards

List of Parameters Classified by Purpose of Use

Related to monitoring

Torque boost

Setting

Name Factory Setting Remarks

Explanation of Functions Parameters

Parameter Name Factory Setting Setting Range EC version

Maximum and minimum frequency

Base frequency, Base frequency voltage

EC version

Remarks Range

Multi-speed operation to to

Acceleration/deceleration time

Frequency setting Hz 120 Acceleration Deceleration time s

Electronic overcurrent protection

DC injection brake

Operation, etc. or the timing of operating

Name Factory

Starting frequency

Load pattern selection

Refer to Refer to ,

Name Factory Setting Setting Range Remarks

Jog frequency

RUN key rotation direction selection

Deceleration Operation Not Activated Regenerative Driving

Stall Prevention OL Signal Operation Fast Output

Stall prevention function and current limit function

CelerationDe Operation Activated

Stall prevention

Where, a =

100

Acceleration/deceleration pattern

Set the acceleration/deceleration pattern

Function Description

Frequency jump

Extended function display selection

Speed display

Use Pr , calibration parameter C4 for

Biases and gains of the frequency setting voltage current

Setting

Name Factory Setting

Set value Hz

How to change the highest frequency

Flicker ... Parameter setting complete

OperationDisplay

Press the SET key to set the value

Voltage gain appears Press the SET key to show the analog

Turn the setting dial to read another parameter

Key to return to

Key twice to show the next parameter

Start-time ground fault detection selection

Output Terminal Function Parameters

Up-to-frequency sensitivity

Output frequency detection

On OFF

Parameter Name Factory Setting Remarks Range

Current Detection Function Parameters

Output current detection functions

Zero current detection

Display Function Parameters

Monitor display

LED

Setting dial function selection

Press the RUN key to start the inverter

Refer to

Maximum output voltage of terminal AM is 5VDC

Restart setting

Restart Operation Parameters

Monitoring reference

Stfstr

Setting Description

Refer to the following table and set the parameters

Automatic restart operation after

Additional Function Parameters

Remote setting function selection

Or PU digital preset frequency

Operation panel operation procedure

Frequency setting storage conditions

Pr Setting

Function E 2PROM

Input terminal function selection

Terminal Function Selection Parameters

JOG

Setting Signal Functions Related Parameters Name

MRS

REX

Referred to

Setting Signal Function Operation Parameters

Output terminal function selection

Same function may be set to more than one terminal

Protective Functions Major Failures for Retries

Pr Setting Number of Retries Alarm Signal Output

Operation Selection Function Parameters

Retry function

Parameter Number Setting Description

PWM carrier frequency

You can change the motor sound

Acceleration/deceleration time, which is a slope up/down to

Applied motor

Voltage input selection

Set the motor used

Reset Selection PU Stop Selection Setting

Reset selection/PU stop selection

Parameter Name Factory Setting Setting Range Remarks

Setting Remarks

Operation panel Restarting method with Shown

Key input from

Cooling fan operation selection

Parameter write inhibit selection

Pr Setting Function

Reverse rotation prevention selection

Operation mode selection

RUN EXT

Mode Signal

Function LED Indication * PU

EXT

MRS

PU operation interlock

Operation mode switching by external signal

X16 Signal Operation Mode

PID control to

Setting Basic PID control configuration

PID action overview

102

Variable output frequency if Deviation X = set point

PID action

Reverse action

Increases the manipulated

RUNFUP,FDN

Wiring example

Deviation

Negative

105

O signals

Parameter setting

Name Setting Description

106

Adjustment procedure

END

Calibration example

107

Start

Set point input calibration

Detector output calibration

108

Automatic torque boost selection

Auxiliary Function Parameters

Slip compensation

11.2

Operating conditions

110

Ordinary V/F control and torque boost Pr , Pr are valid

Meter frequency meter calibration Japanese version

Parameter Name Factory Setting Remarks

Calibration Parameters

Motor primary resistance

112

Flicker ... Parameter setting complete

Meter frequency meter calibration NA and EC version

When the FR-PU04 is used, make calibration with Pr 114

Operation

Display

Parameter clear

Alarm history clear

Erases the alarm history

Clear Parameters

Operational functions

Symbol Switching Type

Operation mode-based functions

118

Communication settings

14.1

Communication-related parameters

Description Setting

119

CR LF

Computer programming Communication protocol

Operation Run Running

Inverter Monitor Parame

121

Data format

Reply data from inverter to computer during data write

Reply data from inverter to computer during data read

Control codes

Signal Ascii Code Description

Data definitions

Send data from computer to inverter during data read

STX ACK ENQ

123

HFF

124

Instruction Data

H7F

Page

Setting items and set data

126

FF =

Nication Tion

127

Calibra

HEC

Description Data

Error Code List

Error Definition

128

Program example

Operation at alarm occurrence

Communication error

General flowchart

Operation and speed command write

Location Selection N8 Pr Operation Command write

N9 Pr Speed Command write

Explanation of table External

Link start mode selection

N8 Pr operation Command write

N10 Link start mode Setting is enabled when Pr = Selection

14.4 E2PROM write selection

15.2

Parameter Unit FR-PU04 Setting

Parameter unit display language switching

N13 Setting Display Language

N16 100

PU contrast adjustment

N15 PU contrast adjustment Setting is enabled when Pr =

PU main display screen data selection

PU disconnection detection/PU setting lock

Monitor display and Resetstop key are valid

N17 Setting PU Disconnection Detection PU Setting Lock

136

Functions

OC1 FR-PU04

Errors Alarms

Error alarm definitions

Major failures

OV1 FR-PU04

138

OC2 FR-PU04

OC3 FR-PU04

THT

139

OV3

THM

OPT FR-PU04

140

OHT FR-PU04

OLT FR-PU04

PUE

Minor failures

For only the type having the RS-485 communication function

141

142

Write errors

Er1 FR-PU04 Control Mode

143

Er3 FR-PU04 Incr I/P

Er2 FR-PU04 PU/EXT Mode

144

Operator ERR

Resetting the inverter

Correspondence between digital and actual characters

Actual Display

Motor remains stopped

Troubleshooting

Motor current is large

Speed greatly differs from the setting

Motor rotates in opposite direction

Acceleration/deceleration is not smooth

Motor produces annoying sound

Operation mode is not changed properly

Operation panel display is not operating

Parameter write cannot be performed

Periodic inspection

Precautions for Maintenance and Inspection

Precautions for maintenance and inspection

Check items

Interval Daily

Insulation resistance test using megger

Pressure test

Daily and periodic inspection

Daily 1 year

151

Inspection Description

Interval

Inspection Interval

Checking the inverter and converter modules Preparation

Checking method

Module device numbers and terminals to be checked

Inverter Model No Fan Type

Replacement of parts

Part Name Standard Replacement Interval Description

Cooling fan

AIR Flow

Relays

Smoothing capacitors

Typical Measuring Points and Instruments

Measurement of main circuit voltages, currents and powers

Measuring Point Remarks Instrument Reference Measured Value

Pf1=

Pf2=

158

Measuring Remarks Instrument

Measuring Point

RH, RM, RL, MRS

RES-SD

160

Cations

Specification List

Phase 200V power supply

Ratings

Phase 400V power supply

Single-phase 200V power supply

Single-phase 100V power supply

Common specifications

NA, EC

Outline Drawings

168

Parameter unit FR-PU04 Outline drawing

Panel cut dimension drawing

170

Instructions

Peripheral Selecting Instructions

Selecting Instructions

Handling of secondary side magnetic contactor

Installation of thermal relay

Disuse of power factor improving capacitor power capacitor

Handling of primary side magnetic contactor

Operation

Cable thickness and wiring distance

Wiring

Operating Instructions

Power supply

Installation

Inverter-driven 400V class motor

Rectifying the motor insulation

Suppressing the surge voltage on the inverter side

176

Appendix

Link Data

Func- Parameter tion Number

Data Code Computer

Extension

178

Data Code Computer Link Parameter Extension

Read

179

180

Name Link Data Tion

Link Parameter Extension Setting Data Code 7F/FF

181

Data Code Computer Func

Print Date Manual Number Revision

Manual number is given on the bottom left of the back cover

![]() Avoid hostile environment where oil mist, fluff, dust etc. are floating, and install the inverter in a clean place or put it within an enclosed box where floating bodies will not enter. When placing the inverter inside a box, determine the cooling system and box dimensions so that the ambient temperature of the inverter will fall within the permissible temperature range (refer to page 166 for the specified value).

Avoid hostile environment where oil mist, fluff, dust etc. are floating, and install the inverter in a clean place or put it within an enclosed box where floating bodies will not enter. When placing the inverter inside a box, determine the cooling system and box dimensions so that the ambient temperature of the inverter will fall within the permissible temperature range (refer to page 166 for the specified value).![]() The inverter may become hot locally, so do not mount it to combustible material such as wood.

The inverter may become hot locally, so do not mount it to combustible material such as wood.![]() Mount the inverter to a wall in a vertical direction.

Mount the inverter to a wall in a vertical direction.![]() By setting the operation panel, the inverter can be run at the speed as high as

By setting the operation panel, the inverter can be run at the speed as high as![]() Setting the DC injection brake operation voltage and operation time to values higher than the factory settings can cause the motor to overheat (electronic overcurrent protection trip).

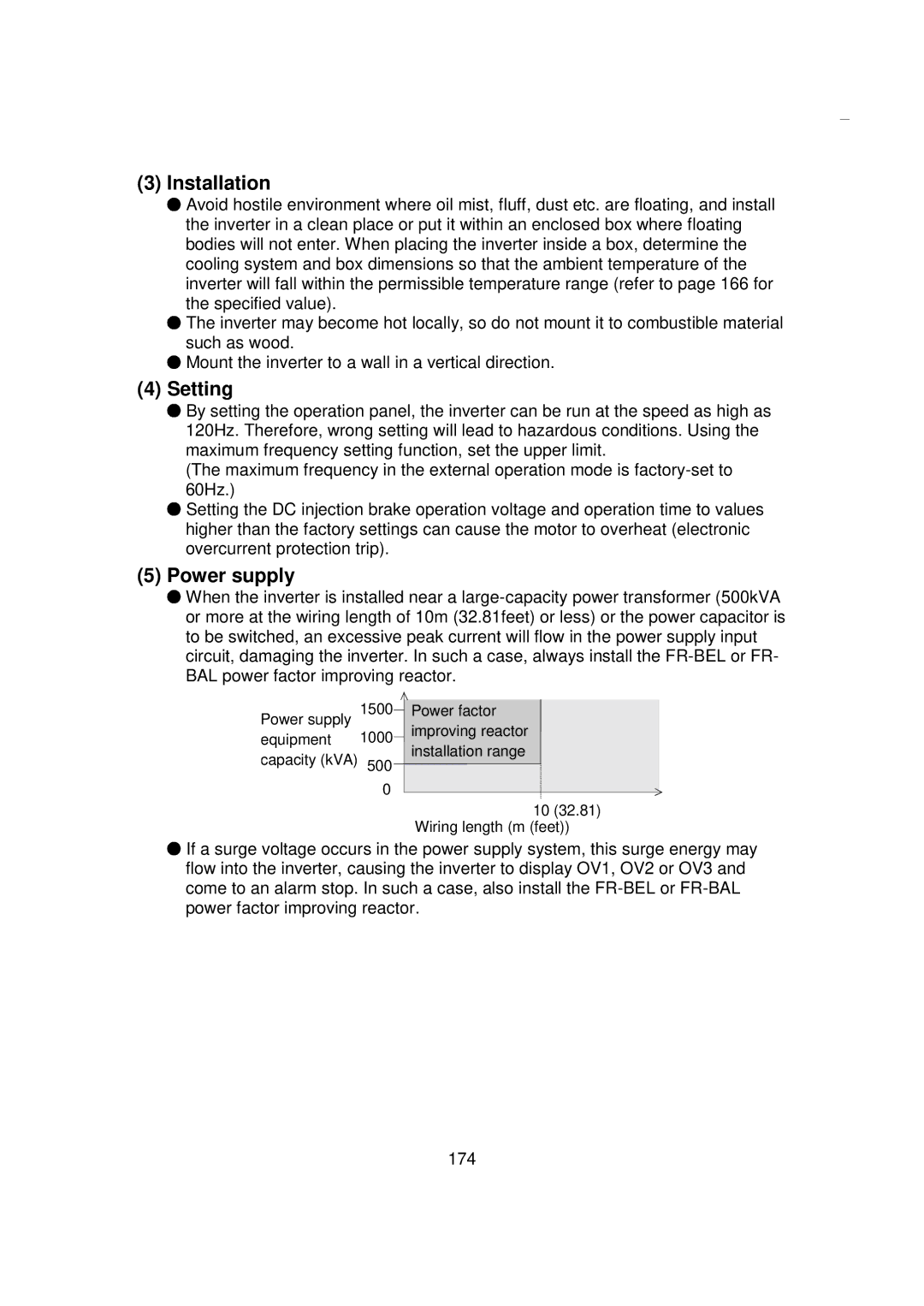

Setting the DC injection brake operation voltage and operation time to values higher than the factory settings can cause the motor to overheat (electronic overcurrent protection trip).![]() When the inverter is installed near a

When the inverter is installed near a ![]() If a surge voltage occurs in the power supply system, this surge energy may flow into the inverter, causing the inverter to display OV1, OV2 or OV3 and come to an alarm stop. In such a case, also install the

If a surge voltage occurs in the power supply system, this surge energy may flow into the inverter, causing the inverter to display OV1, OV2 or OV3 and come to an alarm stop. In such a case, also install the