STUDIO3511/4511

Toshiba TEC Corporation

Service of Machines

General Precautions Regarding the Installation

Main Service Parts for Safety

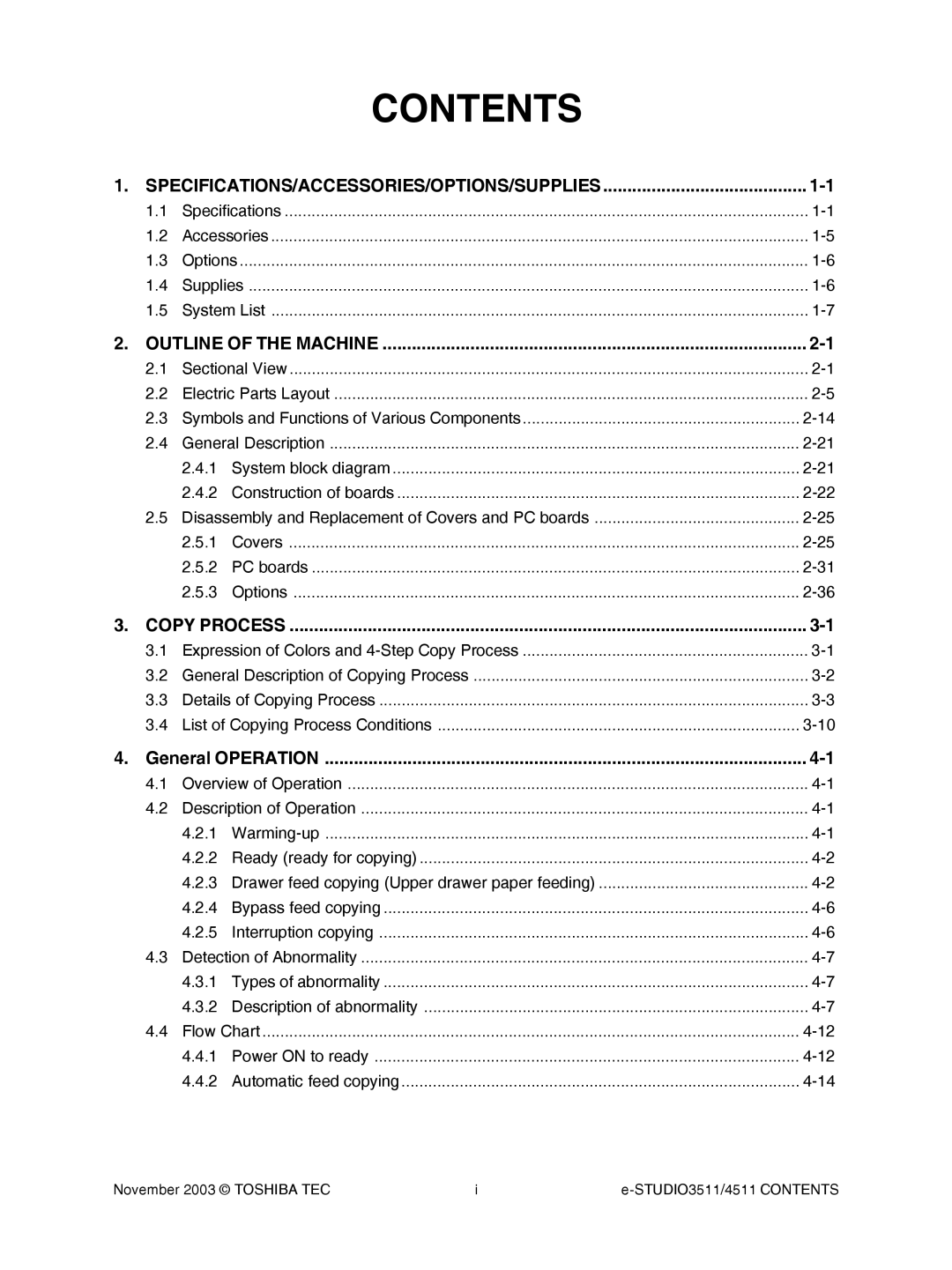

Contents

Control circuit for the exposure lamp

Control Panel

10-1

10.1

10.2

10-5

12-1

12.1

12.2

12.3

15-1

15.1

15.2

15.3

STUDIO3511/4511 Contents November 2003 Toshiba TEC

Specifications

SPECIFICATIONS/ACCESSORIES/OPTIONS/SUPPLIES

ADU PFP LCF

System copy speed

To 550 sheets 64-80 g/m2 17-22 lb. Bond

Automatic duplexing unit Stackless/switchback type

Sheets 64-80 g/m2 17-22 lb. Bond

M2 17-22 lb. Bond

718

Accessories

Supplies

Options

STAPLE-2000

System List

Radf

STAPLE-600

STUDIO3511/4511 Specifications November 2003 Toshiba TEC

Front side view

Outline of the Machine

Sectional View

Drum cleaning blade

Recovery blade

Drum cleaner brush

Toner recovery auger

Rear side view Drive system

Scan motor

Drum cleaner brush motor

Main motor

Transport motor

Front side

Electric Parts Layout

Unit construction

A4 series

Scanner unit Motor, sensor, lamp

LT series

EXP

DH1

Switch, PC board, heater, thermostat, other part

ASD/AUD/CND/SAD/TWD models Standard NAD/MJD models Option

Control panel unit

Process unit Motor, sensor, switch, clutch, solenoid

Laser unit

Motor, switch

S25 S26 M13 Front side

Transport unit

Paper feeder unit

CLT3

CLT5

Automatic duplexing unit

Bypass unit

SFB CLT6 SOL3

ADU CLT7

Drive unit

Fuser unit

HDD NIC BRK

PC board unit

LGC SYS

Symbols and Functions of Various Components

Sensors and switches

CCL-R-POS-SW

CCL-F-POS-SW

CST-U-TRY-SNR

CST-L-TRY-SNR

Solenoids

Electromagnetic clutches

PC boards

Thermistors and thermostats

Lamps and heaters

Others

Transformer

24GeneralDescription

Function of each board CCD board

Construction of boards Construction diagram of boards

Page

HVT

Receiving tray

Disassembly and Replacement of Covers and PC boards

Covers Front cover / Toner bag

Front lower cover

Tray back cover

Front right cover

Left cover

Left upper cover

Left rear cover

Front upper cover

Right upper cover

Right rear cover

IH terminal cover

Right rear hinge cover

Right lower cover

Right front hinge cover

Rear cover

Upper rear cover

Hard disk HDD

PC boards Logic PC board LGC board A-1 LGC board case

LGC board

System control PC board case SYS board case

NIC board / System control PC board SYS board

Remove 4 screws and take off the SYS board case

Flow

Power supply unit

High-voltage transformer

Fuse board FUS board

Noise filter

Options MR-3015 Reversing Automatic Document Feeder Radf

Driving PC board DRV board

Page

KD-1011 Paper Feed Pedestal PFP

Heater is installed

KD-1012 Large Capacity Feeder LCF

Page

Lift up the equipment and take off the LCF

MJ-1022 Hanging finisher When PFP/LCF is not installed

Remove 2 screws Lift up the finisher and take it off

When PFP/LCF is installed

Page

MJ-1023 Console finisher

MJ-1024 Console finisher

Page

MJ-6004 Hole punch unit

Page

KN-3511 Bridge unit

Remove 2 screws Lift up the punch unit and take it off

November 2003 Toshiba TEC

Expression of Colors and 4-Step Copy Process

Copy Process

Photocon

General Description of Copying Process

Details of Copying Process

CCD board

White background Image is not Developed

Photoconductive

Photoconductive Layer Aluminum Base

Blade cleaning

Recovery blade Drum rotation

List of Copying Process Conditions

Pressure roller Silicon sponge

STUDIO3511/4511 Copy Process November 2003 Toshiba TEC

Overview of Operation

General Operation

Description of Operation

Warming-up

Drawer feed copying Upper drawer paper feeding

Ready ready for copying

Page

Page

Scan motor fwd

Interruption copying

Bypass feed copying

Description of abnormality A-1 Add paper

Detection of Abnormality

Types of abnormality

STUDIO3511/4511 General Operation November 2003 Toshiba TEC

Paper jam E010 → The copying operation is Stopped

Registration clutch turned on ↓ Approx 1.2 sec

Approx 1.2 seconds

Registration clutch turned OFF

Exit sensor detects jamming of the trailing edge Paper

After approx 1.3 seconds

Paper jam E020 → The copying operation is

November 2003 Toshiba TEC STUDIO3511/4511 General Operation

Power on to ready

Flow Chart

Ready

Automatic feed copying

Main charger on

YES

Control Panel and Display Panel

Control Panel

Items Shown on the Display Panel

Display

Tray Full Ready

Saddle Stitch

Change Drawer To Correct Paper Size

Copying

This Size Paper

Check Paper

Large Capacity Feeder Cannot Punch

Counter

Department

To Correct Media Type Press Basic

Radf

Structure

Dot matrix LCD circuit

Load Frame

Data Transmission

Frame

Method of LED display ex Displaying Copy

LED display circuit

Slide the stopper and pull it out

Disassembly and Replacement

Stopper

November 2003 Toshiba TEC STUDIO3511/4511 Control Panel

Remove 16 screws and take off the KEY board

Function

Scanner

Construction

Mirror-2 Mirror-3

Scan motor

PS-ACC-350

Scanning drive circuit

Input/output signals

Onno YES

Initialization at power-ON

OFF YES

On no YES

General description

Control of Exposure Lamp

PWA-CCD CCD PWA-CCDPWA-SLG

CPU

Exposure lamp

Control circuit for the exposure lamp

Shading correction

General Description of CCD Control

Opto-electronic conversion

Process of detection of original size

Automatic Original Size Detection Circuit

Principle of original size detection

APS-1 APS-2

APS-3

ST-R

APS-C APS-R APS-1 APS-2 APS-3

APS-C APS-R APS-2 APS-3

Original LEDPhototransistor

SLG board cooling fan

Original glass

Lens cover

LT series

Automatic original detection sensor APS sensor A4 series

Lens unit

Carriages-1

Carriage-1

Carriage Refer to the Service Handbook for more details

Scanning section control PC board SLG board

Platen sensor

Carriage home position sensor

Followings are the boards used for image processing

Image Processing

General Description

CCD

-201 shows the image processing section of this equipment

Configuration

Asic

Asic ACS

SYS Board PWA-F-SYS-350

Features

Example

Functions of image processing circuit

’ = + b +

Example Reduction

Example Enlargement

Paper

November 2003 Toshiba TEC STUDIO3511/4511 Image Processing

Laser Driving PC Board LDR Board

LGC Board PWA-F-LGC-350

Laser Optical Unit

Writing Section Overview

Structure

STUDIO3511/4511 Laser Optical Unit November 2003 Toshiba TEC

Deviation

STUDIO3511/4511 Laser Optical Unit November 2003 Toshiba TEC

Laser power comparison circuit Laser driver Circuit Constant

Polygonal motor reference clock signal

Polygonal motor ON/OFF signal

Laser Unit Cooling Fan

Polygonal Motor

Laser optical unit

Laser unit cooling fan

Drive System

Construction

Main Motor

Drive circuit of main motor

Signal level of motor circuit

Transport Motor

Drive circuit of transport motor

Developer Motor

Developer motor rotational direction signal

Developer motor on signal

Developer motor reference clock signal

Normal Out of control Developer motor PLL signal

Developer motor drive unit

Black developer lifting clutch

Developer motor

Remove 2 screws and take off the developer motor

Transport motor drive unit

Setscrew

Transport motor drive unit Connector

Main motor drive unit

Tension plate

Motor

STUDIO3511/4511 Drive System November 2003 Toshiba TEC

General Descriptions

Paper Feeding System

Page

Paper Feeding Section Sectional View Front side

Paper Feeding Section Drive System Rear side

Operation of bypass pickup roller

Operation of drawer pickup roller

Separation of paper

Bypass feeding

General operation From power-ON to ready status

Ready status

Drawer feedingD-1 Lower drawer

Stop

Drive Circuit of Tray-up Motor

IN1 IN2 Brake CCW

Bypass unit A-1 Bypass unit

Bypass tray slide guide width detection PC board

Bypass pickup roller

Bypass transport roller

Bypass paper sensor

Bypass pickup solenoid

Bypass separation roller

Bypass feed roller

Bypass feed sensor

Lower drawer feed sensor/Side cover opening/closing switch

Remove the arbor, shaft and spring

Upper drawer feed sensor/Registration sensor

Registration roller

Feed clutch

Drawer feeding unit E-1 Drawer feeding unit

Separation roller

Remove 1 screw and take off the separation roller holder

CLUTCH-6-L

Pickup roller

Feed roller

Remove the pulley, one-way clutch and 3 E-rings

6Drawer tray-up sensor and Drawer empty sensor

Drawer paper stock sensor

Tray drive unit

Tray drive unit

Registration guide

Lower transport clutch Low/High speed

Middle guide

Drum Related Section

Functions

Page

IC7

Output Control Circuits of High-Voltage Transformer

CPU

Drum Temperature Detection Circuit

Temperature/Humidity Sensor

Operation

Charger Wire Cleaner

Drive circuit

Cleaner unit

Cleaner unit

Main charger grid

Main charger unit B-1 Main charger unit

Remove 1 screw and take off the pad guide

Charger wire

Wire pad

Drum

Remove the base

Drum cleaner brush

Cleaner Drum cleaning blade

Recovery blade

Remove the discharge LED

Drum thermistor

Discharge LED unit F-1 Discharge LED

Charger cleaner detection switch

Charger cleaner motor

Toner bag full detection sensor-2

Ozone exhaust fan

Temperature/Humidity sensor

Ozone filter

Latch

Page

Developer Unit

Color auto-toner sensor Mixer Developer sleeve

Toner motor

Black Toner Cartridge Drive Unit

General descriptions

Functions

Black Developer Unit

Black developer unit drive section

Converter

Black auto-toner sensor circuit

LCA301-1

Magnetic circuit

STUDIO3511/4511 Developer Unit November 2003 Toshiba TEC

Black developer unit lifting mechanism

Color Developer Unit

Gear G21

Color developer unit drive section

Color auto-toner sensor circuit

Page

Color toner supply

CDVDON-0 CDVAON-0

High-Voltage Transformer Output Control Circuit

Developer material

Black developer unit A-1 Black developer unit

Doctor blade

Pour the developer material

Auto-toner sensor

Developer sleeve

Remove 2 screws and take off the doctor blade

Mixer

Color developer unit B-1 Developer material

Take off the mixer from the hole of front side

Discharge the developer material Pour the developer material

Gear assembly

Procedure for replacing an oil seal

Take off the black developer toner supply unit .7 K

Black developer lifting unit

Black toner supply unit

Remove 2 screws and take off the cleaner rail stay

Cartridge switch with the whole bracket

Black toner supply auger unit

Remove 2 screws and take off the toner motor

STUDIO3511/4511 Developer Unit November 2003 Toshiba TEC

Revolver Unit

STUDIO3511/4511 Revolver Unit November 2003 Toshiba TEC

Drive of Revolver Unit

Revolver motor

Revolver Motor Drive Circuit

Home position detection

Operation

Escape position movement

During warming-up

During image quality control

Color developer unit

Color toner cartridge

Rear Front

Color toner cartridge sensor

Remove 1 screw and take off the color toner cartridge sensor

Revolver home position sensor

Revolver unit

Lock lever

Remove 5 screws and take off the bracket

Internal cooling fan

Transfer Unit

STUDIO3511/4511 Transfer Unit November 2003 Toshiba TEC

Page

Outline of 2nd transfer

Outline of 1st transfer

LCA-301-1

High-Voltage Power Supply

1000V

PWA

Transfer belt unit

Loosen 3 screws and take off the bracket

Transfer belt

Stand plate short

1st transfer roller

Transfer belt home position sensor-2

Transfer belt home position sensor-1

Transfer belt cleaning unit

Remove 1 screw and take off the bracket on the front side

Conductive tape

Harness clamp Transfer belt cleaner auger motor

2nd transfer unit

2nd transfer roller

2nd transfer roller contact clutch

Paper clinging detection sensor

2nd transfer roller position detection sensor

Paper clinging detection sensor Bracket

Page

Principle of the Sensor

Image Quality Control

YES

Flow Chart of Control Procedure

Various image forming conditions

Image quality sensor / Image quality sensor Shutter solenoid

Fuser Unit / Paper Exit Section

Functions

Page

Heater Control Circuit

Configuration

Image of Current Flowing form a to B

Book Diagram of High Frequency Power Supply

Heating principle of IH Heater

+5VSW

IH control circuit interface

IH2 on

IH1 on

FAX

For ASD, AUD, CND

OFF

Control of the surface temperature of the fuser belt

Temperature detection section

Energy Saver

Reference

PC4/AN4

Condtion Priority of error checking

Abnormality in the IH control circuit

IH error

Exit Motor Drive

Control Circuit of Exit Motor

Oil roller

Rear side

Cleaning roller

Fuser roller / Fuser belt guide

IH coil

Bearing Fuser belt guide

Fuser belt

Separation finger

Separation finger unit

Thermostat

Pressure roller

Thermistor

Remove 2 screws and take off the thermostat from the bracket

Exit sensor / Exit finger / Transport guide

Exit roller

IH control board cooling fan

IH control PC board IH board

Scraper

Flow

Automatic Duplexing Unit ADU

Description of Operations

Page

Page

Page

Unit msec

Equipment

ADU entrance sensor ADU exit sensor ADU clutch ADU motor

Exit sensor Registration sensor Registration clutch

Drive of ADU

Yes

Command signal

Operation of DC Output Circuits

Power Supply Unit

Output Channel

November 2003 Toshiba TEC STUDIO3511/4511 Power Supply Unit

Fuse

Charger cleaner motor Power supply Power supply cooling fan

Bridge unit +24VD2

F54A Semi time-lag +24VD4

Toshiba

Configuration of Power Supply Unit

PWR-EN

Sequence of Power Supply

PWR-DN

Scanner

AC Wire Harness

STUDIO3511/4511 Power Supply Unit November 2003 Toshiba TEC

PC Boards

PWA-F-LGC

PWA-F-SLG PWA-F-CCD PWA-F-SDV

PWA-F-DRV

PWA-F-ADU

PWA-F-LDR PWA-F-SNS

PWA-F-DSP PWA-F-KEY

PWA-F-FUS ASD/AUD/CND models Standard, MJD model Option

PWA-F-FIL

NAD/SAD/TWD models Standard

STUDIO3511/4511 PC Boards November 2003 Toshiba TEC

Page

Kanda NISHIKI-CHO, CHIYODA-KU, TOKYO, 101-8442 Japan