Studio 500P

12G9609

United States Government Rights

Table of contents

Service checks

Symptom tables

Messages and error codes

Accessing service menus Diagnostics mode

Diagnostic aids

Additional useful menu locations

Configuration menu Config Menu

Removal procedures

Handling ESD-sensitive parts -1 Adjustment procedures

Connections

Connector locations and connections

Assembly 39 Kiosk-vertical and horizontal paper adapters

Page

Avis relatif à l’utilisation de laser

Laser notices

Laser

Declaração sobre Laser

Avvertenze sui prodotti laser

Avisos sobre el láser

Lasermeddelelse

Laserinformatie

Laser-melding

Laser-notis

Japanese Laser Notice

Korean Laser Notice

Consignes de sécurité

Safety information

Informações de Segurança

Sicherheitshinweise

Pautas de Seguridad

Informació de Seguretat

Definitions

Preface

Eneral information

Onfigured model

Print speed and performance print speed

Specifications

Resolution

Data streams

Memory configuration

Opti ons Duplex 500 page option 15.6 23.4 11 lb

Dimensions

Description Height Width Depth Weight Printer Studio 500P

High voltage model

Power requirements

Electrical specifications

Low voltage model

Acoustics

Environment

Media s pecifications

Xecutive Folio1 Tatement1 Universal2 ¾ E nvelope Nvelope

Page

Grain long 20 to 36 lb bond

Paper

Paper characteristics

Weight

Selecting print media

Labels

Card stock

Storing print media

Print area

Tools required

Avoiding jams

Acronyms

User status and attendance messages

Diagnostic information Start

Symptom tables

Service errors 9xx.xx’s

Navigation buttons

Understanding the printer operator panel

Menu

Stop

Understanding the menus

128MB 449MH

Power-On Self Test Post sequence

High-capacity feeder 2000-sheet symptoms

Symptom tables

Base printer symptoms

Go to Input trays service check on

Paper tray symptoms

Duplex option symptoms

Envelope feeder symptoms

Diagnostic information

Service error codes

Messages and error codes

Go to 920.xx-Cold fuser

Desired temperature Noisy thermistor signal

During steady state Fuser not receiving AC power

Service error codes

Chickens for slope Noisy thermistor signal

Service error codes

Go to 922.xx-Cold fuser

922 Hot roll reached final Low wattage or incorrect lamp

922 Hot roll did not reach Low wattage or incorrect lamp

922 Hot roll took too long to Low wattage or incorrect lamp

922 Hot roll timed out Low wattage or incorrect lamp

To reach desired Excessive load on the fuser

Go to 924.xx-Hot fuser

Go to 923.xx-Hot fuser

Go to 925.xx-Hot fuser

Go to Main fan on

Go to Printhead service

Go to Cartridge fan service

Go to Toner sensor service

Go to Main drive service

Inner shield removal on

Go toMain drive service

See Low voltage power

Board. See System board

Through 950.60 Eprom

Go to 950.00 through

Eprom mismatch failure on

2-77. or go to

Cover removal on

Upper front cover removal

On page 4-11 or Upper front

See Interconnect card

Assembly removal on

Following system board, duplex

User status displays

Error Sub Display text Description/action Code

User attendance messages

Error Sub Primary message Description/action Code

May be a poor connection or a hardware failure

StapleSmart finisher service check on

Go to StapleSmart finisher service check on

Check on page 2-113 or Input trays service check on

Following occurs

Or reconnect it

Button assembly service check on

Actions may be taken

Reset Standard USB Port

Jobs may not be restored

Go to Scheduled maintenance on

Formatted Scheduled Maintenance

User status message Explanation

User line 2 link messages

Check device connection messages

User message Explanation

Sensor Test input tray on

Error Sub Description Possible causes Action Code Codes

Input sensor service

Go to Input sensor service

Go to Fuser exit sensor

Drive service check on

Go to Cover closed switch

Cable service check on

Removal on

See Fuser assembly

Sensor service check on

To Fuser exit sensor

Not be functioning correctly

Functioning properly. Go to

499,999 Diagnostic information

Preserve data

Assembly removal on

Assembly removal on

Turn media over to reduce

Between 0 and 99,999 202 Is covering exit

Assembly removal on

Between 100,000 199,999 202 Is covering exit

Assembly removal on

Bounced. Fuser

Assembly removal on

Assembly removal on

Assembly removal on

Count between 400,000 499,999 202 Is covering the exit

Assembly removal on

Assembly removal on

Assembly removal on

Count is not available 202 Is covering the exit

Jam displayed on

Jam displays on

Operator panel on

Duplex Feed 2 on

Pass. See Duplex Feed

Continue selected

Error Sub Description Possible causes Action Code Codes

Tray autocompensator pick

Roll assembly removal on

Problems with excessive static electricity buildup

Service checks

Bin mailbox service check

Bin x is Full-message that bin x is full does not display

Xx Paper Jam-Check Bin 1 displays

Ready-Binx Full displays and paper feeds into bin

Xx Service Error displays

Xx Error code service check

Main fan

Xx Fan service check

Cartridge fan service check

Panel board. See Operator panel board removal on

Through 950.29 Eprom mismatch failure

Model Board bar code Corresponds to P/N…

Through 950.60 Eprom mismatch failure

See System board and inner shield removal on

Charge roll service check

Pin number Cover open Cover closed

Cover closed switch/cable service check

Dead machine service check

Switch status

Voltage on CN2-1 on the LVPS. The voltage should measure

23x.xx jam code Jam location

Duplex option service check

Duplex paper jams

Xx Jam displayed on operator panel

Xx Jam displays on the operator panel

Error codes on

Envelope feeder service check

Xx Service Error, envelopes fail to feed from the hopper

Xx Paper Jam displays, envelope stops in feeder paper path

Connector locations at Low voltage power supply on

Fuser service checks

Xx-Cold fuser service check

Redrive assembly removal on

LVPS. See Low voltage power supply removal on

Lvps assembly. See Low voltage power supply removal on

System board assembly. See System board and inner shield

Fuser assembly. See Fuser assembly removal on

Xx-Cold fuser check

Connector locations at Low voltage power supply removal on

Cover assembly.Fuser narrow media sensor removal on

Board. See System board and inner shield removal on

Xx-Hot fuser service check

Cover assembly see Fuser narrow media sensor removal on

Fuser assembly removal on page 4-26. If incorrect, replace

Sensor removal on

Fuser exit sensor service check

Fuser exit and fuser narrow media sensor status chart

Fuser narrow media sensor removal on

Fuser narrow media sensor service check

Fuser exit and fuser narrow media sensor status check

Assembly. See Fuser assembly removal on

Fuser solenoid service check

High-capacity feeder input tray service check

Capacity feeder option control board

Paper out sensor flag

Elevator moves in one direction only

Pin Color Paper size

Paper size switch not selecting paper size that is selected

Excessive noise or vibration

High-capacity output stacker service check

High-capacity output stacker option

Optional 250-sheet and 500-sheet trays

Input sensor service check

Input trays service check

Xx Paper Jam Check Bin x, Post incomplete

Printer does not recognize Tray x is installed

Tray x Empty displays when tray x has paper in the tray

Paper from Tray x does not reach the pass thru sensor

Interconnect card service check

Xx Paper Jam user

Main drive service check

No buttons work

Operator panel service check

One or more operator panel buttons fail

Operator panel display

Flash Memory Options

Options service check

Error Code 976.xx Network Card x x=Network card 1, 2, or

Error Code 977.xx Network Card

Standard Bin message

Output bin sensor standard tray service check

Output expander service check

Xx Paper Jam-Check Bin x, Post incomplete

Service Bin

Double feeding paper

Paper feed service check

Failures occur mainly near the bottom of the stack of paper

Paper fails to feed from the multipurpose tray

Paper size sensing service check

Paper activate springs and ITC switches

Printer does not recognize the paper size selected

Run the Parallel Wrap tests on

Parallel port service check

Print quality service check

Print quality-all black

Print quality-random marks

Print quality-blank

Print quality-background

Print quality-blurred or fuzzy print

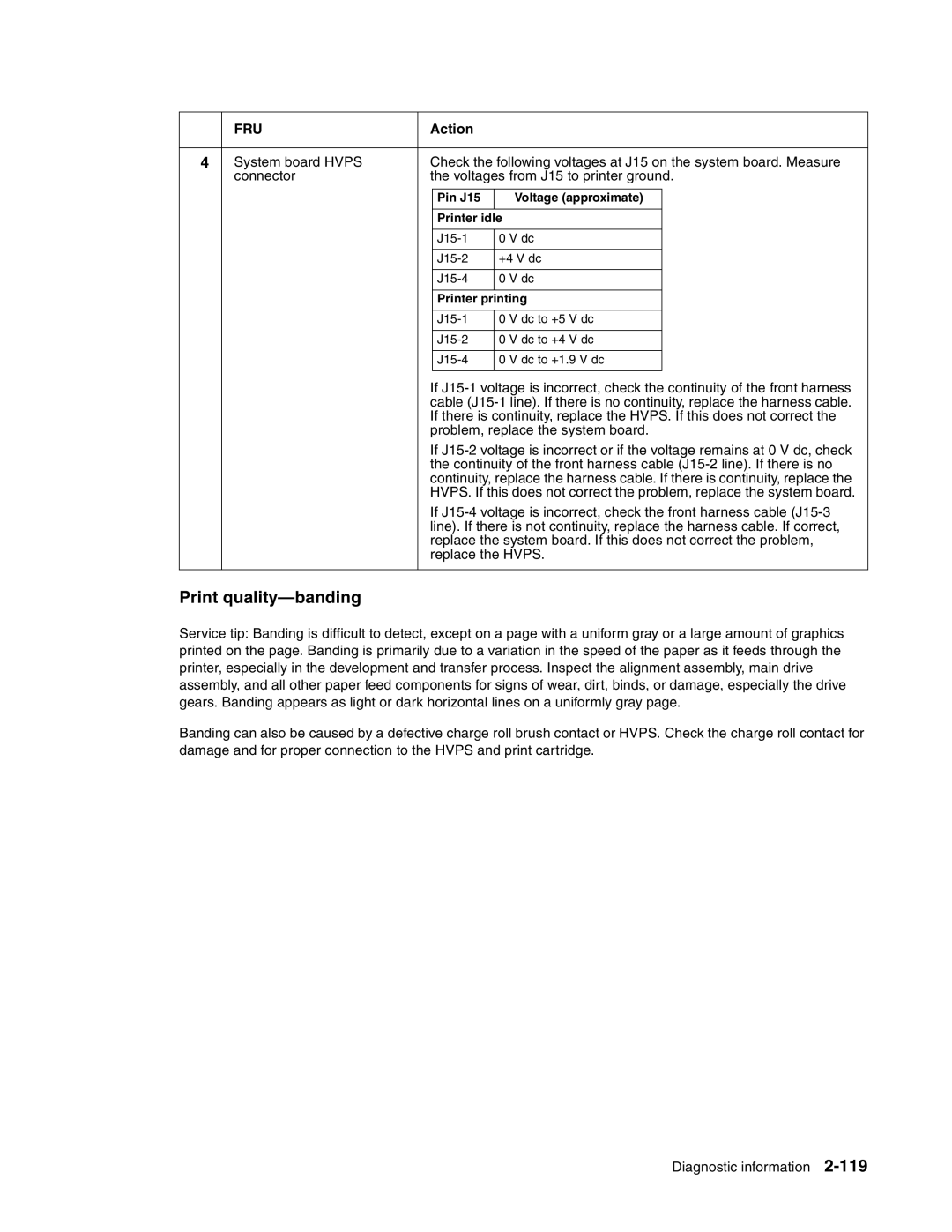

Print quality-banding

Print quality-residual image

Print quality-black bands on outer edges

Print quality-toner on backside of printed

Print quality-light print

Service error code Explanation

Printhead service check

Signature button assembly service check

Diagnostic information

Page

Diagnostic information

System board service check

Toner sensor service check

Quality-background on

Transfer roll service check

See Configuration menu Config Menu on

Diagnostic aids

Accessing service menus

See Diagnostics mode on page 3-2 for more

Available tests

Diagnostics mode

Entering Diagnostics mode

See Configuration ID on

See Disk Test/Clean on

See Defaults on

See Engine Setting 1 through 4 on

Exiting Diagnostics mode

Variable Description Value Direction of change

Quick Test

Select Single or Continuous

Input source tests

Print quality pages Prt Quality Pgs

Dram Test

Panel Test

Button Test

Parallel Wrap tests

Cache Test

Quick Test duplex

Serial Wrap tests

Sensor Test duplex

Top Margin duplex

Duplex Motor AA BB CC DD EE FF

Motor Test duplex

Duplex Feed

Sensor Test input tray

Feed Tests input tray

Order sheets Output bins Are fed

Feed Tests output bins

Feed To All Bins

Sensor Test Output Expander

Sensor Test standard output bin

Diverter Test

Sensor Test high capacity output stacker

Sensor Tests 5-bin mailbox

Diagnostic aids

Quick Disk Test

Base Sensor Test

Flash Test

Disk Test/Clean

Perm Page Count permanent page count

Defaults

Engine Setting 1 through Model Name

Count

Edge to Edge

Configuration ID

Parallel strobe adjustment Par x Strobe Adj

Fuser Page Count

EP Defaults

Fuser Temperature Fuser Temp

Gap Adjust

Print Log

Display Log

Clear Log

Exit Diagnostics

Available menus

Configuration menu Config Menu

Entering Configuration Menu

Maintenance page count Maint Cnt Value

Print quality pages Prt Quality Pgs

Maintenance page counter reset Reset Maint Cnt

Paper source Size sensing

Download Emuls Demo Mode

Panel Menus

Ppds Emulation

Env Prompts

Factory Defaults

Energy Conserve

Paper Prompts

Additional useful menu locations

Printing menu settings

Menu settings

Autocompensator operation

Theory

Option microcode

Autoconnect cabling and connectors

Duplex Option

Paper Jam 200/201

Paper Jam Check MP Feeder

Paper Jam Check Env Feeder

23x and 24x jams

201 Paper Jam Remove Cartridge

Page

Paper Jam Open Rear Door

23x Paper Jam Open Duplex Rear Door

Diagnostic aids

Repair information Handling ESD-sensitive parts

Printhead assembly adjustment

Adjustment procedures

Fuser solenoid adjustment

Gap adjustment

Step B

Paper alignment assembly adjustment

Step a

Covers removals

Removal procedures

Fuser wiper cover assembly removal

Paper support removal

Redrive cap cover removal

Left door removal

Redrive door

Remove the redrive cap. SeeRedrive cap cover removal on

Right cover removal

Page

Page

Upper front cover removal

Installation notes

Upper front cover latch removal

Upper front cover outer bezel removal

Multipurpose feeder/lower front cover assembly removal

Right cover handle holder removal

Left cover handle holder removal

Left and right frame extensions

Pass thru plate

Remove the redrive assembly. See Redrive assembly removal on

Laser cover removal

Page

Bevel gear removal

Installation

Cartridge duct removal

Developer drive assembly removal

ESD cover removal

Developer drive coupler kit removal

Fuser assembly removal

Installation notes

Fuser exit sensor removal

Remove the fuser. See Fuser assembly removal on

Installation

Fuser exit sensor flag and spring removal

Spring replacement

Page

Fuser lamp removal

Remove the fuser assembly. See Fuser assembly removal on

40X0123

Description Fuser Lamp 115

40X0122

Fuser Lamp 220

Fuser narrow media sensor removal

Replacement

Fuser narrow media flag and spring removal

Page

Fuser to Lvps AC cable removal

Installation

Page

Fuser top cover removal

Page

Fuser transfer plate removal

Gear release link removal

High voltage power supply removal

Page

Inner paper deflector assembly removal

Input sensor removal

Integrated tray autocompensator assembly removal

Page

Integrated tray autocompensator pick roll assembly removal

Installation

Interconnect card assembly removal

Low voltage power supply removal

Page

Main fan removal

Main drive assembly removal

Page

Page

MPF arm assembly removal

MPF lower paper deflector

Installation note

MPF pick tire removal

MPF solenoid assembly removal

Page

Page

Installation note

Operator panel board removal

Remove the left door. See Left door removal on

Operator panel buttons removal

Outer shield removal

Paper alignment assembly removal

Page

Paper bin full sensor flag removal

Paper size sensing board removal

Power takeoff shaft and spring removal

Remove the laser cover. See Laser cover removal on

Printhead removal

Redrive assembly removal

Signature button contact assembly removal

System board and inner shield removal

Toner sensor removal

Transfer roll assembly removal

BAB

Upper front cover hinge assembly removal

Upper paper deflector assembly removal

4061-xx0

USB board assembly removal

System board

Connector locations and connections Connections

System board see System board on

Connector Pin no Signal

Narmedia

Bldchall

PSIZE2

Autoconnect

Connector Pin no Signal static

Fuser Board

Fuser Board not a FRU Connectors

Stacker board

High-capacity output stacker board

High-capacity Pin

Interconnect card

High voltage power supply

Connector

CN no Signal

Connector CN pin Signal

Low voltage power supply

Output expander control board

Page

Connector locations and connections

Page

Scheduled maintenance

Preventive maintenance

Safety inspection guide

Lubrication specifications

Page

Model name Configuration Machine type

Parts catalog How to use this parts catalog

Assembly 1 Covers

Assembly 1 Covers

Assembly 2 Frame

Assembly 2 Frame

Assembly 3 Frame

Assembly 3 Frame

Assembly 4 Frame

Assembly 4 Frame

Assembly 5 Printhead

Assembly 5 Printhead

Assembly 6 Paper feed-autocompensator

Assembly 6 Paper feed-autocompensator

Assembly 7 Paper feed-multipurpose feeder

Assembly 7 Paper feed-multipurpose feeder

Assembly 8 Paper feed-alignment

Assembly 8 Paper feed-alignment

7-19 has been removed from This document intentionally

Assembly 10 Integrated 500-sheet paper tray

10-1

Assembly 11 Drives-Main drive and developer drive

11-1

Assembly 12 Hot roll fuser

12-1

Assembly 13 Transfer/charging

13-1

Assembly 14 Electronics-power supplies

14-1

Page

Assembly 15 Electronics-card assemblies

Assembly 16 Electronics-shields

16-1

Assembly 17 Cabling diagrams

Assembly 18 Cabling diagrams

Assembly 19 Cabling diagrams

19-1

Assembly 20 Cabling diagrams

20-1

Assembly 21 Cabling diagrams

Frame assembly with solenoid and cable

42S ervice Manual

Assembly 24 Optional 500-sheet paper drawer

Assembly 25 Optional 500-sheet paper tray

20G0888 Duplex assembly-500-sheet

Assembly 26 Duplex option

Assembly 27 Envelope feeder

48S ervice Manual

Assembly 35 High-capacity feeder

Assembly 35 High capacity feeder

Assembly 36 High-capacity feeder

36-1

Assembly 37 High-capacity feeder

Assembly 38 High-capacity feeder

64S ervice Manual

Numerics

Index

Hardware Tests

Fuser narrow media sensor flag and spring

Buttons 2-106,4-67,7-3 description

Page

Page

Page

Page

Part number index

Printhead assembly includes all cables

Redrive door assembly 250 sheet 000/010

Laser cable assembly

Laser printhead cable assembly

Part number index

Page

Part number index

Page

Part number index

Page

500P 4061 Wiring diagram