WARNING TAGS AND LABELS

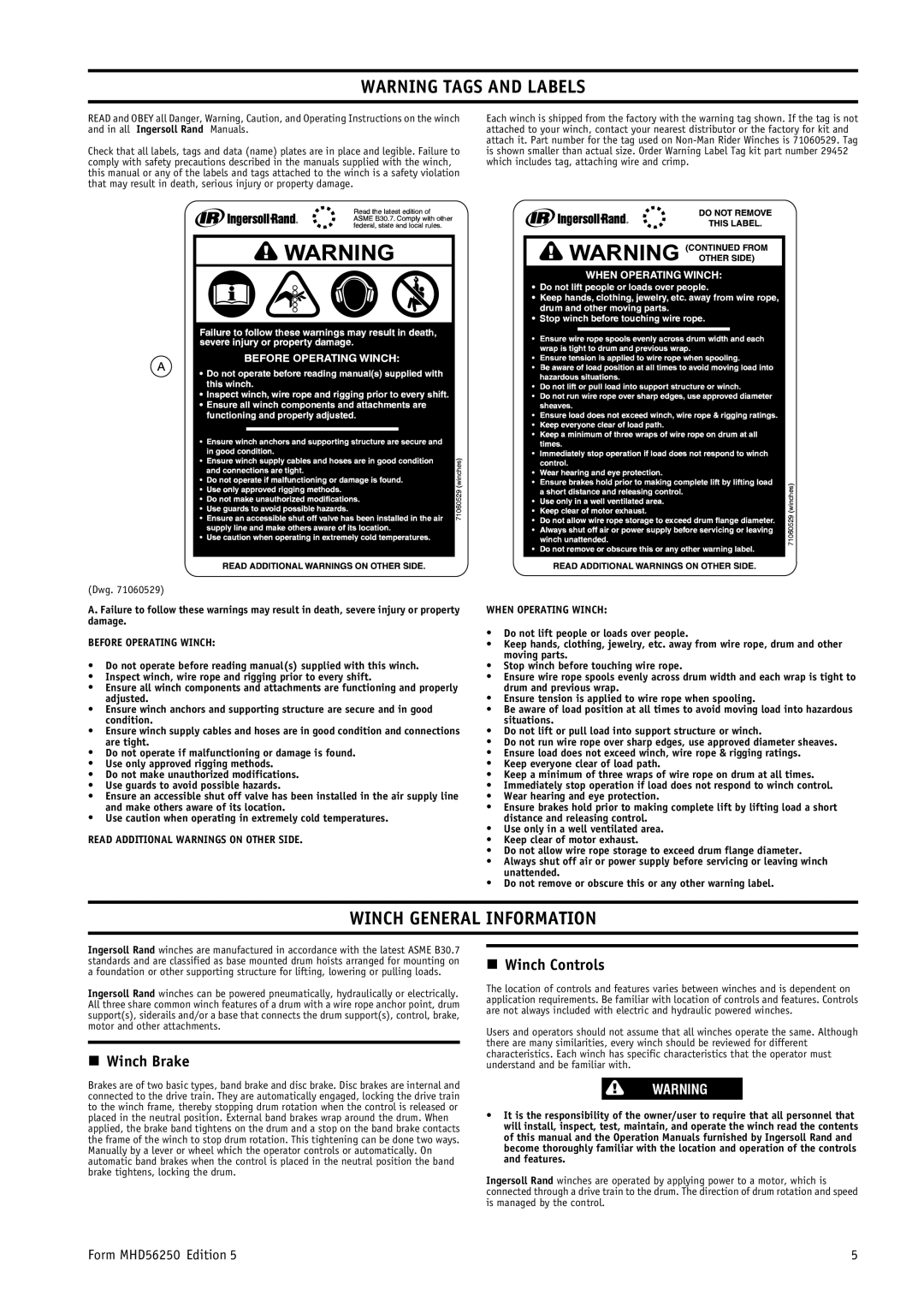

READ and OBEY all Danger, Warning, Caution, and Operating Instructions on the winch and in all Ingersoll Rand Manuals.

Check that all labels, tags and data (name) plates are in place and legible. Failure to comply with safety precautions described in the manuals supplied with the winch, this manual or any of the labels and tags attached to the winch is a safety violation that may result in death, serious injury or property damage.

(Dwg. 71060529)

A. Failure to follow these warnings may result in death, severe injury or property damage.

BEFORE OPERATING WINCH:

•Do not operate before reading manual(s) supplied with this winch.

•Inspect winch, wire rope and rigging prior to every shift.

•Ensure all winch components and attachments are functioning and properly adjusted.

•Ensure winch anchors and supporting structure are secure and in good condition.

•Ensure winch supply cables and hoses are in good condition and connections are tight.

•Do not operate if malfunctioning or damage is found.

•Use only approved rigging methods.

•Do not make unauthorized modifications.

•Use guards to avoid possible hazards.

•Ensure an accessible shut off valve has been installed in the air supply line and make others aware of its location.

•Use caution when operating in extremely cold temperatures.

READ ADDITIONAL WARNINGS ON OTHER SIDE.

Each winch is shipped from the factory with the warning tag shown. If the tag is not attached to your winch, contact your nearest distributor or the factory for kit and attach it. Part number for the tag used on

WHEN OPERATING WINCH:

•Do not lift people or loads over people.

•Keep hands, clothing, jewelry, etc. away from wire rope, drum and other moving parts.

•Stop winch before touching wire rope.

•Ensure wire rope spools evenly across drum width and each wrap is tight to drum and previous wrap.

•Ensure tension is applied to wire rope when spooling.

•Be aware of load position at all times to avoid moving load into hazardous situations.

•Do not lift or pull load into support structure or winch.

•Do not run wire rope over sharp edges, use approved diameter sheaves.

•Ensure load does not exceed winch, wire rope & rigging ratings.

•Keep everyone clear of load path.

•Keep a minimum of three wraps of wire rope on drum at all times.

•Immediately stop operation if load does not respond to winch control.

•Wear hearing and eye protection.

•Ensure brakes hold prior to making complete lift by lifting load a short distance and releasing control.

•Use only in a well ventilated area.

•Keep clear of motor exhaust.

•Do not allow wire rope storage to exceed drum flange diameter.

•Always shut off air or power supply before servicing or leaving winch unattended.

•Do not remove or obscure this or any other warning label.

WINCH GENERAL INFORMATION

Ingersoll Rand winches are manufactured in accordance with the latest ASME B30.7 standards and are classified as base mounted drum hoists arranged for mounting on a foundation or other supporting structure for lifting, lowering or pulling loads.

Ingersoll Rand winches can be powered pneumatically, hydraulically or electrically. All three share common winch features of a drum with a wire rope anchor point, drum support(s), siderails and/or a base that connects the drum support(s), control, brake, motor and other attachments.

nWinch Brake

Brakes are of two basic types, band brake and disc brake. Disc brakes are internal and connected to the drive train. They are automatically engaged, locking the drive train to the winch frame, thereby stopping drum rotation when the control is released or placed in the neutral position. External band brakes wrap around the drum. When applied, the brake band tightens on the drum and a stop on the band brake contacts the frame of the winch to stop drum rotation. This tightening can be done two ways. Manually by a lever or wheel which the operator controls or automatically. On automatic band brakes when the control is placed in the neutral position the band brake tightens, locking the drum.

nWinch Controls

The location of controls and features varies between winches and is dependent on application requirements. Be familiar with location of controls and features. Controls are not always included with electric and hydraulic powered winches.

Users and operators should not assume that all winches operate the same. Although there are many similarities, every winch should be reviewed for different characteristics. Each winch has specific characteristics that the operator must understand and be familiar with.

WARNING

•It is the responsibility of the owner/user to require that all personnel that will install, inspect, test, maintain, and operate the winch read the contents of this manual and the Operation Manuals furnished by Ingersoll Rand and become thoroughly familiar with the location and operation of the controls and features.

Ingersoll Rand winches are operated by applying power to a motor, which is connected through a drive train to the drum. The direction of drum rotation and speed is managed by the control.

Form MHD56250 Edition 5 | 5 |