-Test control functions prior to applying load to winch.

•Wear hearing and eye protection

-Always wear approved protective clothing and equipment when operating the winch.

-Ensure protective clothing and equipment is maintained in good condition.

•Ensure brakes hold prior to making complete lift by lifting load a short distance and releasing control

-Check load does not slip back when winch control handle or pendant is released or returned to neutral.

•Use only in a well ventilated area

•Keep clear of motor exhaust (pneumatic winches only)

-Use mufflers to reduce exhaust noise.

-Exhaust air is discharged with force which can cause injury.

•Do not allow wire rope storage to exceed drum flange diameter

-Refer to “SPECIFICATIONS” section in the winch Product Information manual to determine maximum drum wire rope capacity.

-Follow recommendations for minimum distance requirements between drum flange outside diameter and top layer of wire rope (free board distance).

•Always shut off air or power supply before servicing or leaving winch unattended

-Turn off, lock out power supply and activate control(s) several times to completely

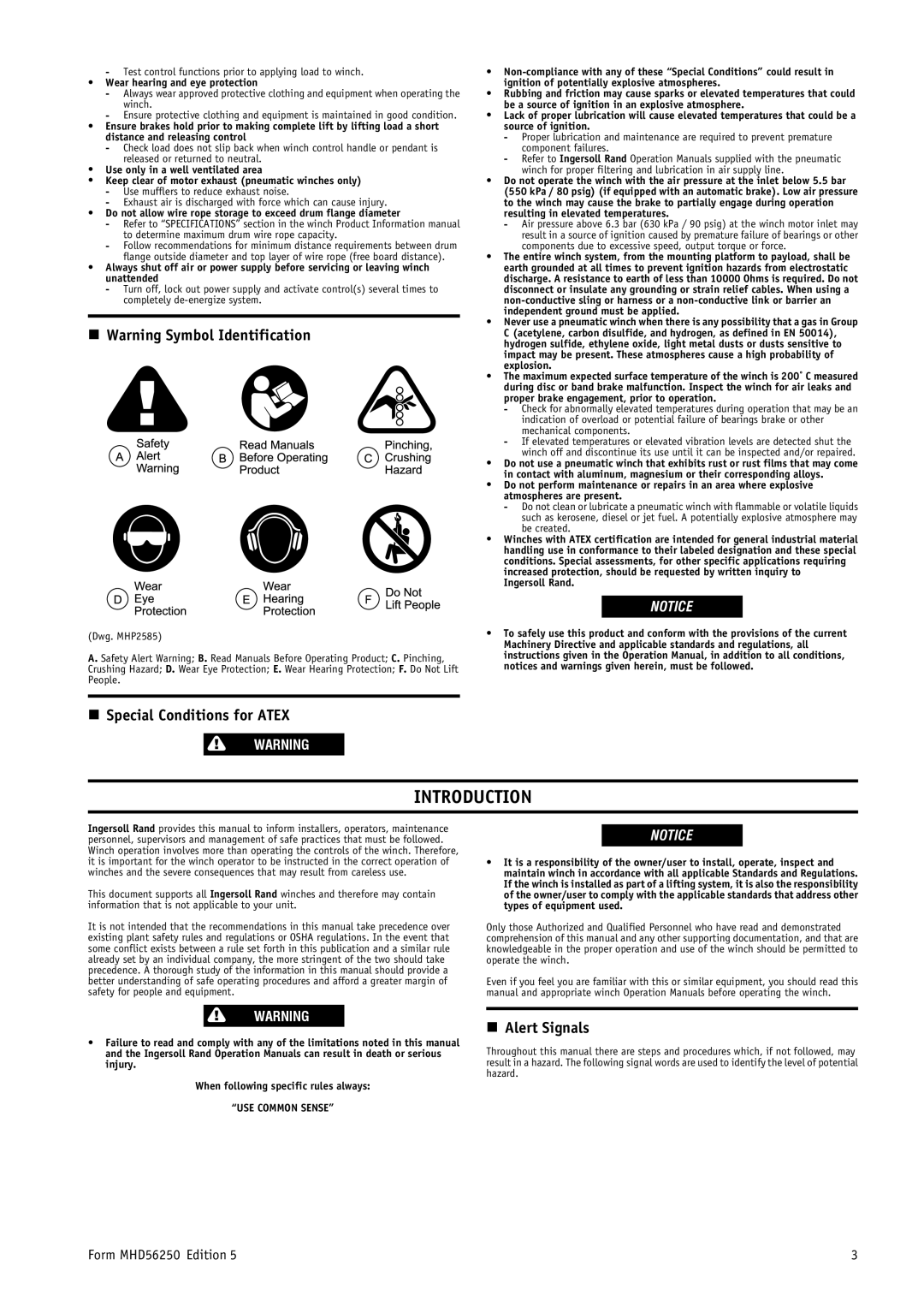

nWarning Symbol Identification

(Dwg. MHP2585)

A. Safety Alert Warning; B. Read Manuals Before Operating Product; C. Pinching, Crushing Hazard; D. Wear Eye Protection; E. Wear Hearing Protection; F. Do Not Lift People.

•

•Rubbing and friction may cause sparks or elevated temperatures that could be a source of ignition in an explosive atmosphere.

•Lack of proper lubrication will cause elevated temperatures that could be a source of ignition.

-Proper lubrication and maintenance are required to prevent premature component failures.

-Refer to Ingersoll Rand Operation Manuals supplied with the pneumatic winch for proper filtering and lubrication in air supply line.

•Do not operate the winch with the air pressure at the inlet below 5.5 bar (550 kPa / 80 psig) (if equipped with an automatic brake). Low air pressure to the winch may cause the brake to partially engage during operation resulting in elevated temperatures.

-Air pressure above 6.3 bar (630 kPa / 90 psig) at the winch motor inlet may result in a source of ignition caused by premature failure of bearings or other components due to excessive speed, output torque or force.

•The entire winch system, from the mounting platform to payload, shall be earth grounded at all times to prevent ignition hazards from electrostatic discharge. A resistance to earth of less than 10000 Ohms is required. Do not disconnect or insulate any grounding or strain relief cables. When using a

•Never use a pneumatic winch when there is any possibility that a gas in Group C (acetylene, carbon disulfide, and hydrogen, as defined in EN 50014), hydrogen sulfide, ethylene oxide, light metal dusts or dusts sensitive to impact may be present. These atmospheres cause a high probability of explosion.

•The maximum expected surface temperature of the winch is 200˚ C measured during disc or band brake malfunction. Inspect the winch for air leaks and proper brake engagement, prior to operation.

-Check for abnormally elevated temperatures during operation that may be an indication of overload or potential failure of bearings brake or other mechanical components.

-If elevated temperatures or elevated vibration levels are detected shut the winch off and discontinue its use until it can be inspected and/or repaired.

•Do not use a pneumatic winch that exhibits rust or rust films that may come in contact with aluminum, magnesium or their corresponding alloys.

•Do not perform maintenance or repairs in an area where explosive atmospheres are present.

-Do not clean or lubricate a pneumatic winch with flammable or volatile liquids such as kerosene, diesel or jet fuel. A potentially explosive atmosphere may be created.

•Winches with ATEX certification are intended for general industrial material handling use in conformance to their labeled designation and these special conditions. Special assessments, for other specific applications requiring increased protection, should be requested by written inquiry to Ingersoll Rand.

NOTICE

•To safely use this product and conform with the provisions of the current Machinery Directive and applicable standards and regulations, all instructions given in the Operation Manual, in addition to all conditions, notices and warnings given herein, must be followed.

nSpecial Conditions for ATEX

WARNING

INTRODUCTION

Ingersoll Rand provides this manual to inform installers, operators, maintenance personnel, supervisors and management of safe practices that must be followed. Winch operation involves more than operating the controls of the winch. Therefore, it is important for the winch operator to be instructed in the correct operation of winches and the severe consequences that may result from careless use.

This document supports all Ingersoll Rand winches and therefore may contain information that is not applicable to your unit.

It is not intended that the recommendations in this manual take precedence over existing plant safety rules and regulations or OSHA regulations. In the event that some conflict exists between a rule set forth in this publication and a similar rule already set by an individual company, the more stringent of the two should take precedence. A thorough study of the information in this manual should provide a better understanding of safe operating procedures and afford a greater margin of safety for people and equipment.

NOTICE

•It is a responsibility of the owner/user to install, operate, inspect and maintain winch in accordance with all applicable Standards and Regulations. If the winch is installed as part of a lifting system, it is also the responsibility of the owner/user to comply with the applicable standards that address other types of equipment used.

Only those Authorized and Qualified Personnel who have read and demonstrated comprehension of this manual and any other supporting documentation, and that are knowledgeable in the proper operation and use of the winch should be permitted to operate the winch.

Even if you feel you are familiar with this or similar equipment, you should read this manual and appropriate winch Operation Manuals before operating the winch.

WARNING

•Failure to read and comply with any of the limitations noted in this manual and the Ingersoll Rand Operation Manuals can result in death or serious injury.

When following specific rules always:

“USE COMMON SENSE”

nAlert Signals

Throughout this manual there are steps and procedures which, if not followed, may result in a hazard. The following signal words are used to identify the level of potential hazard.

Form MHD56250 Edition 5 | 3 |