Connecting the ASD

![]()

![]() DANGER

DANGER

Refer to the section titled Installation Precautions on pg. 5 and the section titled Lead Length Specifications on pg. 16 before attempting to connect the ASD and the motor to electrical power.

System Grounding

Proper grounding helps to prevent electrical shock and to reduce electrical noise. The ASD is designed to be grounded in accordance with Article 250 of the 2005 NEC or Section 10/Part One of the Canadian Electrical Code (CEC).

The grounding conductor shall be sized in accordance with Article

Note: The metal of conduit is not an acceptable ground.

The input power, output power, and control lines of the system shall be run in separate metal conduits and each shall have its own ground conductor.

Power Connections

![]()

![]() DANGER

DANGER

Connect the

The input and output conductors and terminal lugs used shall be in accordance with the specifications listed in the section titled Cable/Terminal Specifications on pg. 154.

An inductor may be connected across terminals PA and PO to provide additional filtering. When not used, a jumper must be connected across these terminals (see Figure 17 on pg. 24).

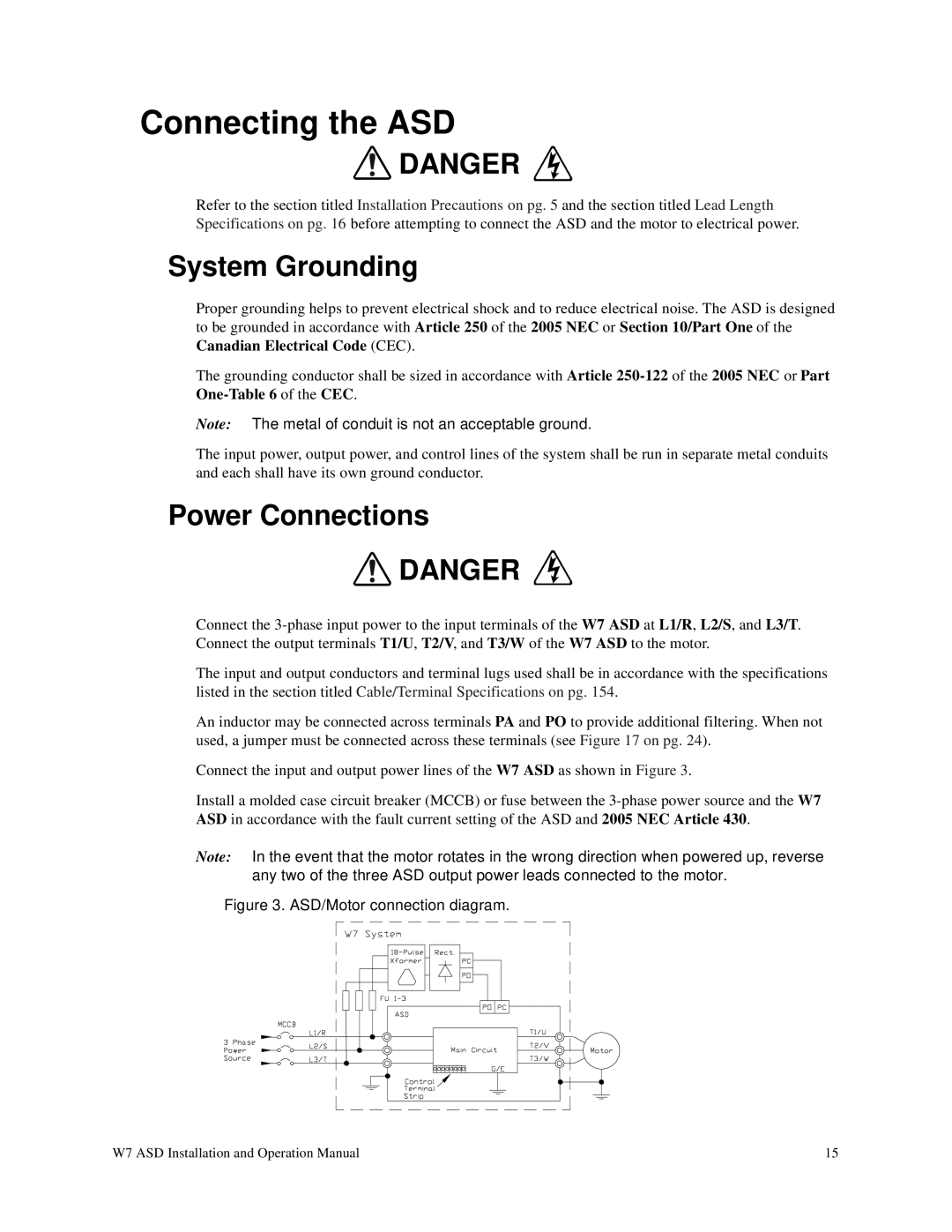

Connect the input and output power lines of the W7 ASD as shown in Figure 3.

Install a molded case circuit breaker (MCCB) or fuse between the

Note: In the event that the motor rotates in the wrong direction when powered up, reverse any two of the three ASD output power leads connected to the motor.

Figure 3. ASD/Motor connection diagram.

W7 ASD Installation and Operation Manual | 15 |