Video Recorder VRX180

Issue 3 03/03 US1I-6228

Issue 3 03/03 US1I-6228

Copyright 2000 by Honeywell Inc

Copyright, Notices, and Trademarks

About This Document

CE conformity

Symbol Meanings What it means

Page

Contents

Online Operations Using Primary Displays

Diagnostic and Error Messages

Tables

Page

Page

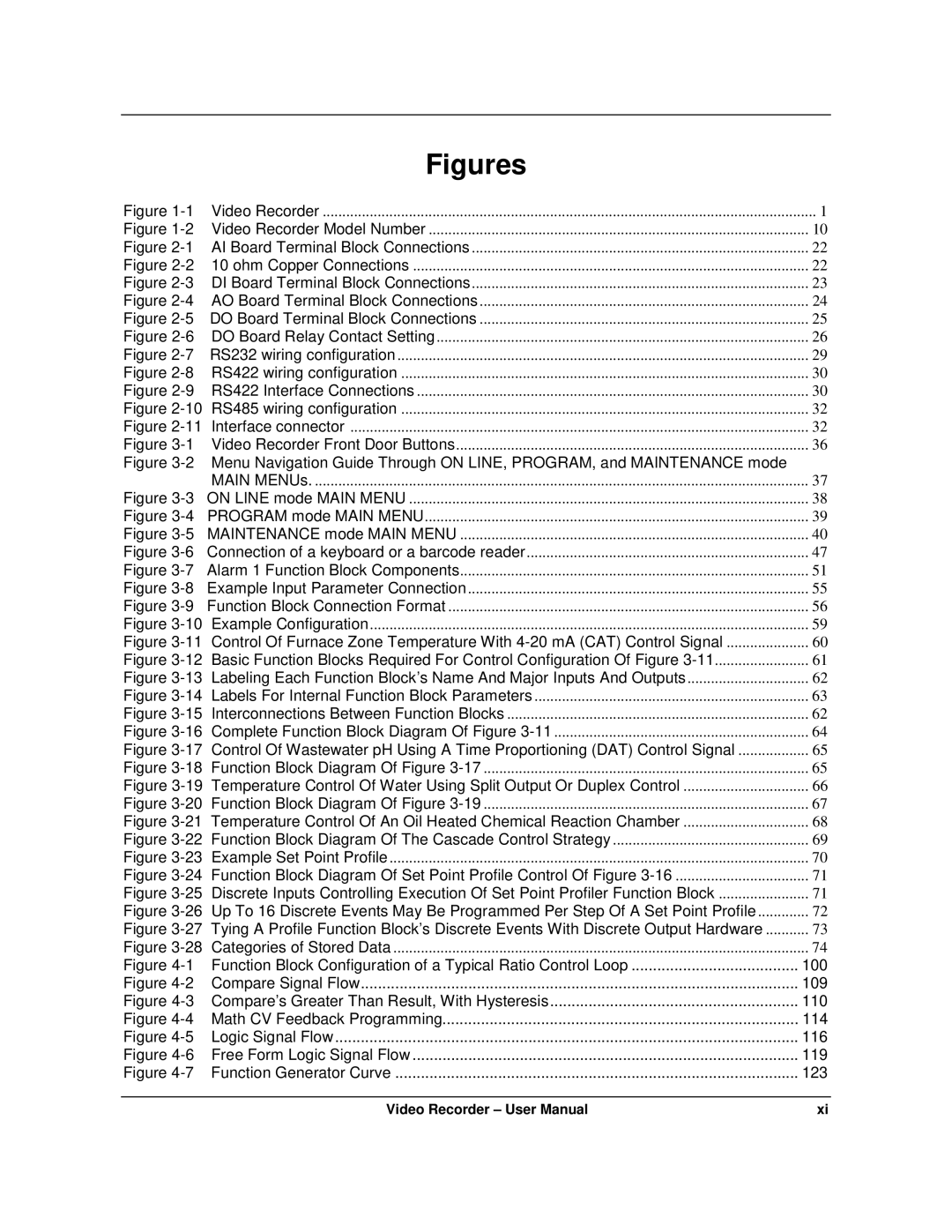

Figures

126

Video Recorder

Video Recorder Overview

Specifications

Specifications

Physical

Environmental

Program Capability

Analog Outputs

Universal Analog Inputs

Digital Inputs AC Inputs DC Inputs

Logic Inputs

Relay Alarm Outputs

Digital Outputs AC Outputs DC Outputs

Performance/Capacities

Time Proportional Outputs TPO on digital output

Analog input accuracy and rated limits

Analog Input Accuracy--Linear types

Millivolts Volts Current Ohms

RTD

Analog Input --Non-linear types

Standards

Video Recorder Model Number

Model Selection Guide

TA B LE IV C O M M UN IC Atio N

Softwares and Support Parts

Topic

What’s in this section?

Unpacking

Recommendations

Panel mounting the video recorder

Installing the video recorder

Wiring the video recorder

Example

Rear cover

Terminal connections

Installation

Step B

Step a

Universal Analog Input Board Specifications

Specification Description

Slot ID

DI Board Terminal Block Connections

Digital Outputs

Do Board Terminal Block Connections

Digital Output Board

Video Recorder

7.1 RS232 wiring configuration

Recorder

Direction Description

Video Recorder Side PC Side

RS422 wiring configuration

7.2 RS422 wiring configuration

10 RS485 wiring configuration

RS485

Arrangement Description

Connecting the RS422/485 link to a computer

Rear connection

Installation

Quick Start Programming

Overview

Modes of Operation

Video Recorder Front Door Buttons

Menu Navigation

Product Info

On Line mode Main Menu

Program mode Main Menu

Maintenance mode Main Menu

Button Functions

Button functions

Online Maint

Online

On Displays

Auto and Manual modes loops Force

Reset

Start

Qwerty keyboard

Text Entry From External Sources

Qwerty Key Equivalents

Button Qwerty key Function

Ascii barcode reader

Connector

Connecting a keyboard or a barcode reader

Lift the rubber cap 1 to

Connect the mini DIN

Installing and removing a floppy disk

Definition

Definition of Function Blocks

Types of function blocks

Flow of information

Function Block Types

Why use function blocks?

Function block

Maximum Purpose Name Available

Components of function blocks

Alarm 1 Function Block Components Input parameter

Output code

Function block parameter

Function Block Output Parameter Name

Function Block Parameter Designators

Block Name Code Type

Function Function Block Output Parameter Name

How to connect an input parameter to another function block

How to program input parameters

Output Code Connection Procedure

Step Action

Function Block Connection Format

How to program an input parameter with a number

Example Programming Discrete Input Parameter with a Number

How to program a discrete input parameter with a number

How to program a simple configuration

How to program function block parameters

Programming procedure

Example Function Block Parameter Selection Procedure

AL 1 Alarm #1

Example configuration

As displayed in the Program

Menu

Programming a Current Driven Heat Treat Element

How to program common configurations

Diagram the function blocks

Label output parameters

15 Interconnections Between Function Blocks

Draw the Feedback connection

16 Complete Function Block Diagram Of Figure

Time Proportioning Relay Driven Pump

18 Function Block Diagram Of Figure

Split Output or Duplex Control

20 Function Block Diagram Of Figure

Cascade Control

22 Function Block Diagram Of The Cascade Control Strategy

23 Example Set Point Profile

Set Point Profile Implementation

Type J Thermocouple

#16

DI3 OS AO1 BC LP1 OV

Categories of Stored Data

Data Storage

11 Data Storage File Extensions

Performing Data Storage

Data Type File extension

Pre-initializing a ZIPdisk on a PC

Initializing a ZIP disk

Data storage considerations

Data Storage Status

Performing Configuration Storage

Process and Diagnostic Data Integrity

Performing Set Point Program Storage

Examples

What’s in this section?

Overview

Programming tips

Program Mode Menu

Program mode menu

Prompt Function

Frequently Used Programming Prompts

Frequently used programming prompts

Prompt Range/Selections Definition

Set Mode

Overview

Enter Labels

Entering labels with the front panel buttons

Entering labels with a Qwerty keyboard

Labels for Function Blocks

Unit

Other Labels

LPM GPH LPS GPM OHM Litr Gram GPS Degc Degf Filenames

File Cycle Dryer

Analog Input Algorithm Selection

Program Analog Inputs

Standard algorithm prompts

Temperature Unit

Custom algorithm prompts

Characteristic What to be aware

Loop Characteristics

Program Control Loops

Control Loop Programming Structure

Programming Procedure

Control Loop Type Menu Selections

CHG Action Soft PID

10 Loop Prompts

Loop Menu Items

Feedback

Engineering

Feedforward

Gain Force Remote

Decimal

Manual Reset

Position Interactive YES, no

Latching YES, no

Reset Limit

RESET#1

RATE#2

Ratio Bias

Setpoint Select

Ratio Setpoint

SETPOINT#2

Soft PID YES, no

SP LOW Limit & SP

SP DEC Slew Limit

High Limit

SP1 Tracking SP2, None

Function Block Configuration of a Typical Ratio Control Loop

Analog output type

Program Analog Outputs

11 Analog Output Types

12 Prompts For Analog Output Types

13 Analog Output Prompts

103

14 Discrete Input Prompts

Program Discrete Inputs

15 Discrete Output Prompts

Program Discrete Outputs

Input

16 CV Types

Program Calculated Values

Type Math Description Package

17 Peak Picking Prompts

Peak Picking

18 Signal Select Prompts

Signal Select

19 Compare Prompts

Compare

Compare’s Greater Than Result, With Hysteresis

Then CVn OS is

20 Compare’s Condition Type and Condition Time Prompts

Sec

Ec ext end

RT Pulse

Pulse

Counter

Preset

21 Counter Prompts

Count Down

22 Math Prompts

Math

Input a Input H

Output High Limit Operator ADD, SUBT, MULT, DIV

23 Free Form Math Prompts

Free Form Math

Input a CN5OV Input B

Input C AI1OV Input D AI2OV Sqrt ABSC/D+5

For this function or value Type this in the equation

24 Free Form Math Functions

Logic

Operator AND, OR, XOR, RESET/SET FF

25 Logic Prompts

TOGGLE/FF, ONE SHOT, Pass Input a

For this operator Definition If this is true Then Result is

26 Logic Operators

27 Free Form Logic Prompts

Free Form Logic

NEG

Example equation using iteration

Example equation using operators and inputs

29 Results of Logic Equation Using Iteration

Order of evaluation

31 BCD Prompts

BIT Enable

Example #1, loading a 2-profile program

Example #2, loading a 4-profile program

This Profile

32 How Profiles Are Saved In Memory

These

These Profiles

33 Function Generator Prompts

Function Generator

Function Block

PID Function Input Generator

34 Interval Timer Prompts

Interval Timer

RESET/RUN

10 Periodic Timer

Periodic Timer

36 Set Up Timer Prompts

35 Periodic Timer Prompts

37 Mass Flow Prompts

Mass Flow

38 Carbon Prompts

Carbon Potential

11 Typical Carbon Potential Control Configuration

39 Relative Humidity Prompts

Relative Humidity

40 F0 Sterilization Prompts

Sterilization

Advanced Splitter Output ADV Splitter

Heat/Cool Configuration

41 Advanced Splitter Prompts

42 Standard Splitter Prompts

Standard Splitter Output STD Splitter

Feedback #2

Output

43 Scaling Prompts

Scaling

High Limit Range LOW

44 Signal Clamp Prompts

Signal Clamp

OUT High Limit LOW Select

High Select

45 1 Point Block Average Prompts

Point Block Average 1 Pt Block Avg

Average Period

46 Rolling Average Prompts

Rolling Average

# of Samples

AVG Period Mins

47 Multiple Average Prompts

Multiple Input Average Multiple Avg

OUT High Limit Input #1- Input #8

48 Cems Block Average Prompts

Cems Block Average

Cems Rolling Average CEM Rolling Avg

Time Units

49 Cems Rolling Average Prompts

Frame Period

50 Alarm Prompts

Program Alarms

Program Totalizers

51 Totalizer Prompts

Program Profiles

52 Constant Prompts

Program Constants

Value

Input High Limit Destination

Gain #1 = Dest = LP 1 GN CV 1 OV

Destination defined

53 Copy Block Prompts

Copy Block

Program Displays

17 Displays Accessible by the Display Buttons

151

54 Display Setup Procedure

Display Setup Procedure

Set Up Trend

55 Set Up Trend 1 Prompts

Set Up Trend 2 3

56 Paper Chart Speed Equivalents to Time Base Selections

Trend Group

58 2 trend group live buffer size Trend Groups

59 4 trend group live buffer size Trend Groups

60 Set Up Bar Graph 1 Prompts

Set Up Bar Graph

Set Up Bar Graph 2 3

Set Up Panel Displays

64 Assign Displays To Keys Prompts

Assign Displays to Keys

Display

Display Format

Trend

Bargraph

65 Enable Features Prompts

Enable Features

66 Security Prompts

Program Security

67 Serial Communications Prompts

Serial Communications

68 Set Clock Prompts

Set Clock

69 Load/Store Config Files Prompts

Load/Store Configuration

Store Config to FILE01 CYCLE01

Disk DRYER01 PROD01

70 Suggested Scan Rates

Scan Rate

Inputs Scan Rate Control

Select Language

71 Data Storage Setup Procedure

Setup procedure

Enable storage

Data Storage

Trend Data

Set Up New Schedules

Setup

Point #12 Storage Mode

Copy Display

LOW Rate

Trend Data 2, 3

Alarms

Events

73 Stored Events

Unit Data

Diagnostics

74 Unit Data Prompts

Start Minute

Select Filename Cycle Dryer

Start Month JAN-DEC

Start DAY

75 Disk capacity Prompts

Disk capacity

Sec 10 sec 30 sec

76 Disk Storage Capacity of 100MB ZIP disk

10 min 30 min Hour

Min

Initializing a disk

Batch Control

77 Filename Extensions Of Data Storage Types

Data set Extension

Overview of the Setpoint Profiler

Profile features

Definitions

Section

RESET/RUN Advance

Schematic of the Setpoint Profiler function block

Start Hold

Shutdown Time

Two types of profiles

Single and Multi-phase Profiles

Two PVs available

Components of a profile

Number of segments

Time Units

Ramp Type = Time

Ramp Type = Rate

Ramp Type = External

External Ramp Type

Soak segment

Guaranteed Soak

Hysteresis

Example of Segment Events

Segment Events

Event 3 State

Example of invalid overlapping loops

Segment Loops

Loop to Segment =

Coordinating operation of multiple profilers

Parameters that control a profile’s execution

Discrete inputs

Parameters That Control Profiler Execution

HOT Start

Definition Triggered Conditions Result Present

Forward

Fast

Last

Shutdown

Segment

Ramp Increment

Program Profilers menu in Program mode

How to set up a profiler

Program Profiler Prompts

Setpoint Profiles Prompts

Setpoint Profiles Menu in Online mode

Load Program Program Number

Load Program

From Memory

Edit Profile Prompts

Auto Cycle Count

Auto Cycle OFF, on

Edit Profile Loops

From Segment #

Time Multiplier

Edit Segments Prompts

Editing Segments

14 Buttons

How to load and run a profiler

How Profiles Are Stored In Memory

How to load programs from memory using Online menu

Step Action Result/Notes

Procedure To Load a Program From Memory Using Online Menu

10 How Profiles Are Stored On Disk

How programs are stored on a disk

11 Disk Program Capacity

201

13 Profiler Starting Procedure

How to start a profiler

How to reset a profiler 15 Profiler Reset Procedure

How to hold a profiler 14 Profiler Hold Procedure

How to shut down a profiler 17 Profiler Shutdown Procedure

11056

PV #2 538.67

00910

3900

SP1 SP2 SP3

21 Segment Editing Procedure

How to edit a profile’s segments

208

Overview

Displays Accessed With Display Button

Display Definition Function Interactive Or view only?

Interacting with Setpoint Trend Display

Interacting With Primary Displays

Prompt Definition

Interacting with Live or Replay Trends

First JAN

Find

Last JAN

Find JAN

TEMP7

Resume Panel4 Display Rotation Procedure

Stop Panel4 Display Rotation Procedure

Interacting with Panel4 Display

Step Action Result

Interacting with Loop Displays

To perform this action Do these steps

2305.5

Display Messages and Symbols

Location

Multiple messages

Color Description shown low to high priority

Message/Symbol Color Description

General Error

Messages and Symbols Elsewhere on Display

220

Menu as displayed Function

Online Main Menu

Floppy Disk Insertion/Removal Procedure

Installing a disk

Data Storage

Typical online data storage tasks

Initializing a disk using a new storage setup

Initializing a disk using the same storage setup

How data is stored

Disk Status

Checking current storage setup

Initialization errors

Error message Definition

Storage Start/Stop Controls

Starting and stopping storage

Prompt Comments

Checking Data Storage Status

Data Storage Replay Procedure

Remaining DDD-HH-MM Trend

Reading Data Storage Messages

Examining replay data

Display alarm summary

Access Summaries

Acknowledging alarms

What happens during an alarm

Alarm Acknowledgment Procedure

Display Alarm History

Acknowledging Diagnostic Messages

What happens during a diagnostic

Diagnostic Acknowledgment Procedure

Delete All Diagnostics

Product Information

Delete All Diagnostics Procedure

Data Entry

233

Setpoint Profiles

Tune Loop Prompts

Tune Loop

Bold items are read-only

Reset #2

Reset #1

Rate #1

PROP. Band #2

Display Tuning

Control Loop Tuning Display

10 Stages Of Pretune

Pretune Loop

Pretune Stopped menu

11 Pretune Stopped Prompts

After Starting Pretune

Before Starting Pretune

Pretune Identifying & Calculating menus

12 Pretune Identifying & Calculating Prompts

13 Pretune Complete Prompts

Pretune Complete menu

14 Pretune Abort Messages

Pretune Abort messages

Message Meaning/User action required

Review Programming

Set Mode

Maintenance

What’s in this section

Calibrate Analog Inputs

Routine Maintenance

AO Module Jumper ST1 Calibrate Analog Outputs

AO Module calibration

Calibrate Analog Output Procedure Step Action

Off-line Diagnostics

Reset Unit

Database Services

Product Information

Mains Frequency

First Time Start

Warm Start Time

Demo

Diagnostic Error Messages

Diagnostic Messages

Internal Error Messages

Internal error messages

253

Abnormal Loop Conditions And Indicators

Loop Error Indicators

Error Messages

Error Messages

256

257

258

Parts Kit Description Kit Part Number

Parts

Kit Description Kit Part Number

Portable case Spare case galvanised Spare painted case

262

Appendix a

Security Bypass Procedure

264

DA2I-6063

Sikkerheskrav

DU2I-6063

Veiligheidsvereisten

FI2I-6063

Turvallisuusmääräykset

FR2I-6063

Consignes DE Securite

GE2I-6063

Sicherheitshinweise

Απαιτησεισ Ασφαλειασ

IT2I-6063

Norme DI Sicurezza

Omgivelser

NO2I-6063

PO2I-6063

Instruções DE Segurança

SP2I-6063

Normas DE Seguridad

SW2I-6063

Säkerhetsföreskrifter

Safety 276

Index

Edit Alarm Setpoints

279

Sales and Service