Jam troubleshooting

Media jams occur when media either does not reach or does not clear the

Jams

Jams occur most often when the following conditions exist:

●Media trays are not correctly loaded or the sliding media guides are not correctly positioned.

●The print media does not meet the specifications listed in the Print Media Guide for the HP LaserJet printer family.

●The media is in poor condition. See “General guidelines for using the ADF unit” on page 28.

●The MFP needs cleaning. See “Cleaning the product” on page 36.

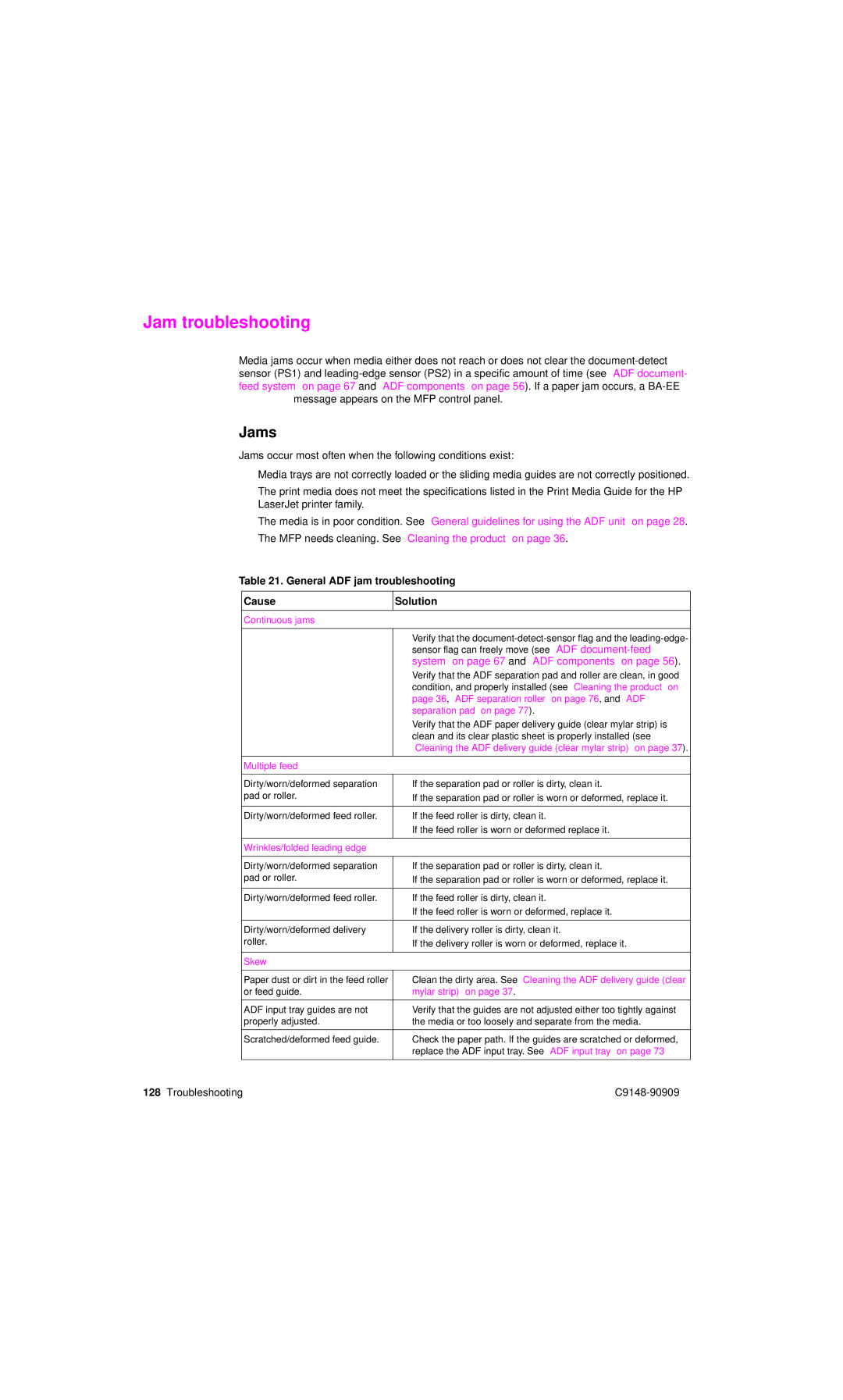

Table 21. General ADF jam troubleshooting

Cause | Solution |

|

|

Continuous jams |

|

|

|

| ● Verify that the |

| sensor flag can freely move (see “ADF |

| system” on page 67 and “ADF components” on page 56). |

| ● Verify that the ADF separation pad and roller are clean, in good |

| condition, and properly installed (see “Cleaning the product” on |

| page 36, “ADF separation roller” on page 76, and “ADF |

| separation pad” on page 77). |

| ● Verify that the ADF paper delivery guide (clear mylar strip) is |

| clean and its clear plastic sheet is properly installed (see |

| “Cleaning the ADF delivery guide (clear mylar strip)” on page 37). |

|

|

Multiple feed |

|

|

|

Dirty/worn/deformed separation | ● If the separation pad or roller is dirty, clean it. |

pad or roller. | ● If the separation pad or roller is worn or deformed, replace it. |

|

|

Dirty/worn/deformed feed roller. | ● If the feed roller is dirty, clean it. |

| ● If the feed roller is worn or deformed replace it. |

|

|

Wrinkles/folded leading edge |

|

|

|

Dirty/worn/deformed separation | ● If the separation pad or roller is dirty, clean it. |

pad or roller. | ● If the separation pad or roller is worn or deformed, replace it. |

|

|

Dirty/worn/deformed feed roller. | ● If the feed roller is dirty, clean it. |

| ● If the feed roller is worn or deformed, replace it. |

|

|

Dirty/worn/deformed delivery | ● If the delivery roller is dirty, clean it. |

roller. | ● If the delivery roller is worn or deformed, replace it. |

|

|

Skew |

|

|

|

Paper dust or dirt in the feed roller | ● Clean the dirty area. See “Cleaning the ADF delivery guide (clear |

or feed guide. | mylar strip)” on page 37. |

|

|

ADF input tray guides are not | ● Verify that the guides are not adjusted either too tightly against |

properly adjusted. | the media or too loosely and separate from the media. |

|

|

Scratched/deformed feed guide. | ● Check the paper path. If the guides are scratched or deformed, |

| replace the ADF input tray. See “ADF input tray” on page 73 |

|

|

128 Troubleshooting |