HWS-1501CSHM3-E-UK HWS-2101CSHM3-E-UK HWS-3001CSHM3-E-UK

Hydro Unit Outdoor Unit

Hot Water Cylinder

HWS-802XWHT6-E HWS-1102H-E HWS-1402XWHM3-E HWS-1402H-E

Contents

Method of Defect Diagnosis

About indication

About symbols

∗ For details, see the schematic

∗ Ground wire of class D grounding

∗ For details, see the parts price list

No modification Do not modify the unit

Do not make additional charge of the refrigerant

∗ Thick gloves such as cotton work gloves

Failure to do so may cause an electric shock

NEW Refrigerant R410A

Safety During Installation and Service

Wall thickness of copper pipe

Installing refrigerant pipe

Steel pipe and joint

Copper pipe

4 Dimension of flare for R410A and flare nut

Flare and precautions

Flare dimension

3 Flare processing related dimension for R410A

5 Tightening torque of flare for R410A Reference values

Flare connecting procedure and precautions

Gauge manifold

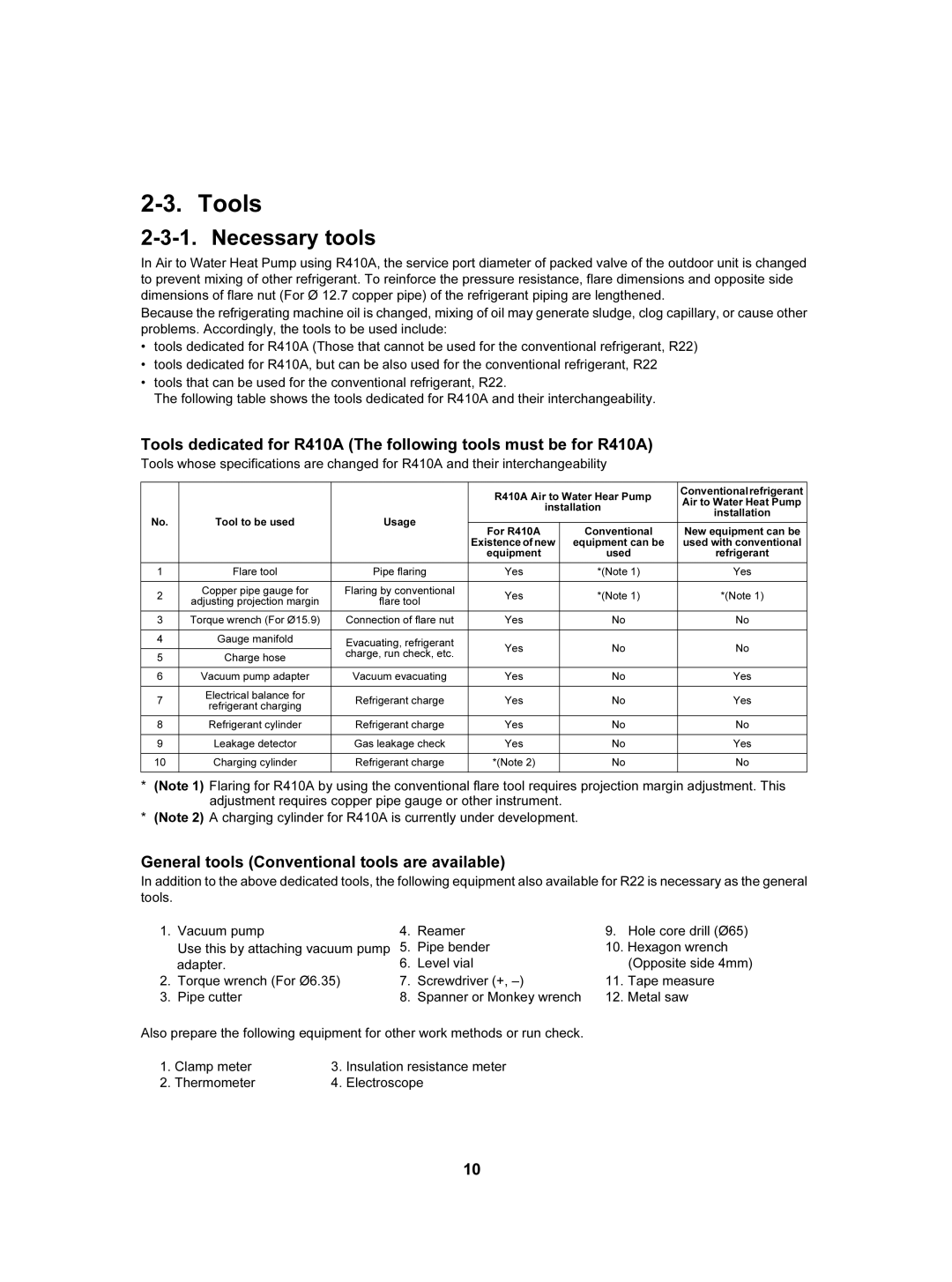

Tools

Necessary tools

General tools Conventional tools are available

For refrigerant charging, see the figure below

Recharging of refrigerant

Gauge manifold Outdoor unit Refrigerant cylinder

Cylinder without siphon

Brazing

Brazing of pipes

Materials of brazing

Flux

Robber plug

Prevention of oxidation during brazing

Specifications

Page

Hydro unit

Outside Drawing

HWS-802H-E

HWS-1102H-E, 1402H-E

HWS-1501CSHM3-E-UK

HWS-3001CSHM3-E-UKHWS-2101CSHM3-E-UK

Block of the outdoor unit

Wiring Diagram

Control board

Hot Water Cylinder Unit

Model name Component name Type name Rating M3-E T6-E

Key Electric Component Rating

HWS-802XWHM3-E, 802XWHT6-E

Model name Component name Type name Rating M3-E T6-E T9-E

US-622KXTMQO-SS

Component name Type name Rating

CAM-MD12TF-15

OFF = 125 ± 4 C, on = 90 ± 5 C

CSH

Model name Component name

Type name Rating

Thermal cut-out

Water Heat Exchange Control Board

F03 250 V, 10 a

P01Red P02White Earth lead wire P09 Black

Outdoor Control Board

D503 Green, Outdoor = Hydro

F700250V,3.15A

Water

Diagram

System Diagram

System

Installation example of water circuit

Outdoor unit Hydro unit

Refrigeration Cycle System Diagram

HWS-802XWHM3-E, 802XWHT6-E/802H-E

HWS-1402XWHM3-E, 1402XWHT6-E, 1402XWHT9-E/1102H-E, 1402H-E

Operational Description

Cooling Temperature setting

Operation Remote control settings

Heating Temperature setting

Hot water supply Temperature setting

Hydro unit

Hot water temperature 40C to 75C

Heating temperature 20C to 55C

Backup heater control

Outdoor unit

Cooling temperature 10C to 25C

Transmit

Hot water cylinder unit

Operation flow and applicable data, etc

TTW sensor

TWI

Zone Operation with heating priority

Pressing the ZONE1, 2 button and then Operation Mode

Starts a cooling operation

Pump priority

Simultaneous operations of hot water supply and cooling

75C Hot water operation

Switches to Hot water Supply operation

HOT Water button set to on HOT Water Boost button set to on

Heating side

Supply heater

HOT Water button set to on

Anti bacteria Anti Bacteria operation

Another 30 minutes can be set with FC0B

Night set back Night SET Back operation Operation

35B 30C 25D 20E

Nighttime low-noise operation Operation

Inverter output change

Hz signal correction

Controller set temperature

Temperature settings Water outlet temperature

TC=TWO

TC TWO

Keep

THO

Keep TSCF-4

TSCF-0

TSCF-2

Non-interlocked with the built-in pump

Circulation pump control Hydro Unit

SW3

Flow rateL/min

SW3 SW2

SW1

Heating operation Night Set Back

1Piping freeze prevention control

Automatic restart control

TWI, TWO, THO

Piping freeze prevention control

TWO

TCB-PCMO3E

Hydro Unit Room temperature thermostat control Option

PMV Pulse motor valve control

Main circuit control current

Settings Yes

Current degradation

Current release control

Number of rotation hold

TL C WE tap + 1 tap/20 secs

For 1402H-E

Hot water supply and heating fan control

For 802H-E

For 1102H-E

OFF

Heating operation starts

Inside brackets For 802H-E

Continuously energized

Not energized

Intermittently energized

Output equal to 40W

802H-E 1102H-E, 1402H-E Heating Cooling TC TWO+2 61C

Method of Defect Diagnosis

Procedure of defect diagnosis Remark

1 Non-defective operation

Check the power supply voltage

About the installation of the temperature sensor

Matters to be confirmed first

How to cancel a check code on the remote controller

Outline of the determination diagram

Procedure of defect diagnosis

How to determine from the check code on the remote control

3TWI

How to diagnose by error code

Defect mode detected by the water heat exchange

2TWO

Diagnostic functional operation Number

Diagnostic functional operation Number

Defect mode detected by the outdoor unit

Diagnostic functional operation Number

Diagnostic functional operation Number

Determination and action

Defect mode detected by the remote control

Diagnostic functional operation

Hydro unit failure detection

Diagnosis flow chart for each error code

A01 Error Pump flow determination

Yes Water outlet

A02 Error Temperature rise and error short circuit

Replace flow switch

Replace TWI, TWO, and THO sensors

Yes TTW 85C is detected Replace TTW sensor

A03 Error Temperature rise and error short circuit

Start

A04 Error Freeze prevention control

A05 Error Piping freeze prevention control

Place buffer tank

Yes Lower set temperature

Remove waste

Water circuit

Yes Defrost outdoor unit

Yes Raise set temperature

Where frost remains

Cooling overload operation

Put water into water circuit Recommended 1 2 Bar

Water cycle contains water

TWI sensor is Attach TWI sensor

A11 Error Release protection operation

Secure water Waste stuck inside Remove waste

A12 Error Heating or Hot water supply heater failure

E04 Error

Yes Replace water heat exchange control board

F03 Error TC sensor failure

F04 Error TD sensor failure

F06 Error TE sensor failure

F10 Error TWI sensor failure

F07 Error TL sensor failure

F08 Error to sensor failure

F17 Error TFI sensor failure

F11 Error TWO sensor failure

F14 Error TTW sensor failure

F19 Error THO sensor detach failure

F18 Error THO sensor failure

TFI s ensor Is attached to pipe

F20 Error TFI detach failure

F23 Error Lo pressure sensor detach failure

Lo pressure sensor Yes Is detached CN207 When operation

L09 Error

F29 Error Eeprom failure

F30 Error Enhanced IC failure

L07 Error

Outdoor Unit Failure Detection

Diagnosis procedure for each check code

Lock compressor Replace it Yes

Board side Wiring connection

Is normal Check and correct

Compressor is normal Yes

Eeprom failure → See F31 details

Heat sink temperature sensor TH failure → See F13 details

Communication failure between MCUs

Check outdoor control board If defective, replace it

Power voltage abnormally Yes

Is cleared, Blower is not blocked

Deal with short circuit Short circuit, etc Yes

Heat sink overheat failure

Outdoor control

SW804 SW801

Way valve invert failure

Element Short circuit

Heating operation

Yes Outdoor fan operates normally Check the same item as

Replace fan motor

Power voltage is normal Check wiring 230ACV ±

Diagram Yes

Correct wiring Replace outdoor board

Correct TE sensor

Characteristic table

TL sensor connector CN604 is connected

TL sensor resistance characteristic is normal

100

Suction temperature sensor TS failure

TS sensor resistance characteristic is normal

TD, TL sensors

101

TC, TWI, TWO, TFI, TTW, TE, TS, to sensors

Rotary Check contents Remark Switch

Operation check by PC board switch

Operation check mode

Operation check mode

103

Component name Check procedure

Brief method for checking the key components

Hydro unit

14.8 ± 1.5 Ω

Outdoor unit

104

802H-E 32.6 ± 3.3 Ω

105

10Hydro unit and Outdoor Unit Settings

Hydro unit Hydro unit Setting

106

Hydro unit Function Code Setting

Details First shipment

107

Nighttime low-noise end time

108

Details Fist shipment

109

Trial Operation

TSC-F

Auto Curve Setting

Set temperature A40 B35 C30 D25 E20 20 T1

110

111

Time Setting

112

Scheduled Operation Setting

Set temperature, day , and time

113

Frost Protection Setting

114

Night Operation Setting

115

Anti Bacteria Setting

116

Hot Water Boost Setting

Nighttime Low-noise Setting

117

Forced Defrosting Setting

Rated Operation Setting

118

Display Function of Set Temperature and Other Settings

119

Failure History Calling Function

120

Outdoor unit Outdoor Unit Setting

121

Function and details

122

123

LED indication

Item setting Temperature sensor

124

Current Compressor PMV openness Operation Pulse Frequency

SW804

Operation when press button switch SW801 is pressed

125

126

SW804 Operation when press button switch SW801 is pressed

127

11How to Exchange Main Parts

Work procedure Remarks

Hydro Unit

Controller holder

Remote controller cable

128

Remote

MgSW

Electric parts assembly

129

Relay board

130

Expansion vessel

Exchange parts name Work procedure Remarks

131

Board

132

Pump

Fixing

Manometer

Exchanger inlet pipe so that the wire is place on

133

134

135

136

Outdoor Unit 2-1. HWS-802H-E

137

CN202 Black

Remove the power source cable from the power

138

Lead

139

Fan motor lead Binding tie Compressor lead, Relay connector

Fan motor

140

Propeller fan Turn it right to loosen

Flange nut

141

142

143

Pulse motor

144

Spring

Valve body

145

146

Valve fixing board

Inverter assembly

147

Heat exchanger

Reactor lead CN05 White

148

Case thermostat, fan motor

Reactor lead Binding tie Reactor body

Name Electric parts Reactor Replacement 1Perform the step

149

Reactor lead

Fixing rubber Projection/Refrigerant cycle side Fan motor

150

Compressor nut 3 nuts

151

152

Positioning Motorized Projection Control valve coil

Pulse motor valve coil 1. How to remove 1Perform the step

153

Recess Pulse motor valve body

154

12Periodic Inspection Items

Inspection items

155

13Part Exploded View, Part List

156

157

002

158

Outdoor Unit

HWS802H-E

159

TD, TL sensor

Inverter Assembly HWS-802H-E

Sensor assembly 701 F6 TS, TE, TD sensor

160

161

Outdoor Unit HWS-1102H-E, 1402H-E

162

163

TS, TE, to sensor

Inverter Assembly HWS-1102H-E, 1402H-E

164

4316V357

165

43158190

Reactor

166