HDP5000 High Definition Card Printer/Encoder User Guide Rev

Part Number L000950

Revision Control Date Document Title Number

Mailsales@fargo.com

Table of Contents

Accessory Procedures

Card Lamination Module

Printer Adjustments

Toolbox

Fargo Workbench Printer Utility

How to use the guide

Manual Description

Safety Messages review carefully

Reviewing the HDP5000 Boot-up Sequence

HDP5000 Process Flow in table format

Step Process

Reviewing the HDP5000 Sequence of Operations

Reviewing HDP5000 Card Printer Sequence of Operations

Reviewing the Lamination Module Boot-up Sequence

Reviewing the Lamination Module Sequence of Operations

Specifications

Introduction

Reviewing the HDP5000 Printer Overview table

Modules

HDP5000 100

Reviewing the HDP5000 Package

Reviewing the HDP5000 front

Reviewing the HDP5000 Card Printer

Display HDP5000 Printer with attached Output Hopper

Regulatory Compliances

Agency Listings

Term Description

File Number E145118

FCC Rules

Environmental Protection China-RoHS

Technical Specifications

Compositions Card Cleaning

HDP5000 and HDP5000-LC

Technical Specifications

Adjustments

Card Sizes

HDP5000 and HDP5000-LC See Card tab under Printer

Technical Specifications

HDP5000 + Dual-Sided Module 11.50H x 17.50W x 9.25D

HDP5000 + Single-Sided Lam Module 12.75H x 25W

HDP5000 + Dual-Sided Module + Dual-Sided Lam Module

HDP5000 and HDP5000-LC

16MB RAM

HDP5000/HDP5000-LC

Print Ribbon

HDP5000 and HDP5000-LC prints or images

HDP5000 and HDP5000-LC see note below

Windows 2000 / XP / Server

HDP5000 with Card Lamination Module

HDP5000 + Dual-Sided Module 22 lbs. / 10 kg

HDP5000 + Single-Sided Lam Module 28 lbs. / 12.7 kg

36 lbs. / 16.4 kg

Functional Specifications

Function Description

Component Description

Printer Components LCD and Softkey Control Pad

Cancel

Printer Components LCD and Softkey Control Pad

Pause

Resume

Printer Components Print Ribbons

Printer Components Blank Cards

Type Description

Printer Components Blank Cards

Printer Components Card Input and Output Hoppers

Printer Components Card Output Hopper and Reject Hopper

Printer Unit Reviewing the Card Lamination Module

Printer Components Transfer Roller

Reviewing the Overlaminates

Term Description Cross Reference

Thermal Transfer Film The Thermal

PolyGuard Overlaminate PolyGuard

Reviewing the CR-80 Patch Size

Reviewing the Overlaminate Design

Symbol as shown to the left

Before performing an operation preceded by this symbol

Performing repair procedures, unless otherwise specified

Hands, as well as thoroughly clean hands to remove oil

Time Requirement

System Requirements

Inspection HDP5000

Unpacking the Printer

Display a See the HDP5000 Printer Installation Guide

Unpacking the Printer

Display B See the HDP5000 Printer Installation Guide

Choosing a Good Location

About Moisture Condensation

Printer Loading Procedures

Step Procedure

Loading the Print Ribbon

Loading the Print Ribbon

Tighten the Print Ribbon

Loading the Print Ribbon

Loading the Clear HDP Transfer Film

Loading the Clear HDP Transfer Film

Tighten the HDP Film

Loading the Clear HDP Transfer Film

Inserting the Card Cleaning Roller

Inserting the Card Cleaning Roller

Remove the protective sleeve from the Card Cleaning Roller

Insert the Card Cleaning Roller into the card input area

Loading the Overlaminate

Loading the Overlaminate

Tighten the Lamination Rolls

Close the Lamination Module Front Cover

Loading the Blank Cards

Load the blank cards into the Card Cartridge, as shown below

Loading the Blank Cards

Connecting Power to HDP5000 Printer and Lamination Module

Connecting Power to HDP5000 Printer and Lamination Module

Connecting Power to HDP5000 Printer and Lamination Module

Printer Driver Installation Procedures

Installing the HDP5000 Printer Driver

Installing the HDP5000 Printer Driver

Click on the Next button to continue with the installation

Read the License Agreement. Select the I accept the terms

License agreement option

Select Local to install a USB Printer

Select Network and enter an IP Address for the Printer

Click on the Next button to begin the installation

Wait during the installation

Step Procedure Applies to USB Printer installation

Connect the USB cable to both the PC and the Printer

Installing the HDP5000 Printer Driver

Click the Finish button Reboot your computer

You have completed this procedure

Open the Driver settings

Printing a Test Print Image

Windows XP or Printers Windows

Will bring up the HDP5000 Printing Preferences window

Printing a Test Print Image

To prevent equipment or media damage, refer to

Using the Security Lock Slot on the HDP5000

Using the Security Lock Slot on the HDP5000

Removing the Output Side Upgrade Cover

Estimated Repair Time 1 minute Step Procedure

Installing the Flipper Module Accessory

Estimated Repair Time 20 minutes Step Procedure

Flipper Module Accessory

Installing the Lamination Module Accessory

Estimated Repair Time 10 minutes Step Procedure

Installing the Lamination Module Accessory

General Troubleshooting

LCD Messages

Safety Messages review carefully

Troubleshooting LCD and Printer Error Message Tables

How to use the LCD Error Message Table example provided

Troubleshooting with the LCD Error Message Table

LCD Error Message Cause Solution

Press Resume or Cancel

Troubleshooting with the LCD Error Message Table

See Cleaning the Printer

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

Cancel Print button or

Cancel button located on

Film Rfid tag is bad

Print

Cancel

Troubleshooting with the LCD Error Message Table

Troubleshooting with the LCD Error Message Table

See Resolving

Troubleshooting with the Printer Error Message Table

Printer Error Cause Solution Message

On Cancel Print

Troubleshooting with the Printer Error Message Table

Troubleshooting with the Printer Error Message Table

Troubleshooting with the Printer Error Message Table

Troubleshooting with the Printer Error Message Table

Troubleshooting with the Printer Error Message Table

Troubleshooting with the Printer Error Message Table

Troubleshooting with the Printer Error Message Table

Troubleshooting with the Printer Error Message Table

Cancel Print

Power and press the Resume

Cord is properly connected, cycle

Button to continue

On the Printer

Cancel Print button or the Cancel

Troubleshooting with the Printer Error Message Table

Troubleshooting with the Printer Error Message Table

Restricted USE ONLYFargo Electronics, Inc

Communications Errors

Resolving the Communication Errors

Resolving the Communication Errors

Printing a Test Image

Reviewing the Alignment Self Test Card

Reviewing the Color Bars Self Test

Reviewing the Device Settings Self Test

Reviewing the Ymck Self Test

Reviewing the Magnetic Self Test

Reviewing the Resin Self Test

Ethernet Option Section

Technical Specification Ethernet Option

Here are the system requirements for Ethernet

Function Requirement

Functional Specification Ethernet Option

Fargo Ethernet option includes these features

Feature Description

Provides an Snmp agent that supports MIB-II

Reviewing the Print Server

Reviewing the Web Page Server

Reviewing the Network Management Interface

Reviewing the Telnet Server

Initiating a Telnet Session

Interface Description

Reviewing the Telnet Command Table

Telnet Command Command Purpose Command Format

Reviewing the Telnet Command Table

Command Purpose Command Format

Newname

Password

Reviewing the Telnet Command Table

Ethernet Web Pages Standard Procedures

Reviewing Web page security

Logging

Accessing the Home

Reviewing the Home

This section provides a display of the HDP5000 Home

Reviewing the Home Page Categories and Fields table

Category Field Purpose

Configuring the Network Settings

Accessing the Network Settings

Select the Network link from any web page of the Printer

Reviewing the Current Settings

Reviewing the Interface

Switching to the Automatic IP Address Mode

Changing to the Static IP Address Mode

Changing to the static IP address mode

See the Reviewing Web page security procedure

Using the Clear Changes button

Using the Media Information

Using the TCP/IP

Using the TCP/IP

See the Using the TCP/IP page procedure

Using the Printer

Reviewing the Printer

See the previous page for descriptions of the fields

Using the System Log

Changing the Log Name

Selecting the Log Type

Step Procedure No event logging

Selecting the Log Destination

Specify one destination for the log

Setting up Email Event logging

Step Procedure Specify email logging

Specifying UDP Event logging

Specifying UDP Event logging

Specifying TCP Event logging

Select the System Log link

Select the TCP Connection radio button

Accepted after you have successfully logged

Specifying TCP Event logging

Using the Administration pages

Using the System Information

Using the System Information

Label textbox

Location textbox

Contact textbox

Changing the Root Password

Using the Reboot pages

Rebooting the Printer

Upgrading the Main Firmware

Upgrading the Main Firmware HDP5000 only

Upgrading the Main Firmware HDP5000 only

Select Reboot when requested. See Display B below

Select the Browse button. See Display a below

Navigate to and select the appropriate file to upload

Using the Print Path

Using the Print Path

Accessing the Ethernet Status LEDs

Using the Help

Reviewing the HDP5000 LED Table

Flash Rate Indicates Green LED

Step Procedure

Step Procedure

Restoring the Factory Settings for Ethernet

Resetting the HDP5000 settings

Changing the HDP5000 LCD Network Settings

Accessing the Network Setup Menu

Changing the Dhcp Setting

Changing the Aneg setting

Network Settings menu Options -Menu Next Network Settings

Resetting Passwords

Saving addresses

Accessing the HDP5000 IP Address

Follow this procedure

Troubleshooting procedures

Command procedure

Follow the Printing a test page procedure

Must match the model of the Printer

Verifying the Printer Connection

Verifying the Printer IP address

Step

Printing a test

Reviewing Frequently-asked Questions

Question Answer

Reviewing Frequently-asked Questions Answer

Reviewing Frequently-asked Questions Answer

Options Menu Network Settings Reset Passwords

Select Start Settings Printers and Faxes

Your Printer Driver Properties

Menu Network Settings Save Addresses

Options Menu Network Settings Dhcp Change

Select the Use the following IP address button on

Select Start Settings Printers and Faxes your

Printer and Printer

Print Test Page button

Network communications using TCP and IP protocols

Term Purpose

Glossary of Terms

MIB

Card Lamination Module

Safety Messages review carefully

Reviewing the Card Lamination Module

Installing the Card Lamination Module

Introduction

Inspecting the Card Lamination Module

Unpacking the Card Lamination Module

Choosing a proper Location

Preventing Moisture Condensation

Installing the Lamination Module Accessory

Installing the Lamination Module Accessory

Adjusting the Lamination Placement on the Card

Adjusting the Lamination Placement on the Card

Display B See Procedural on the previous

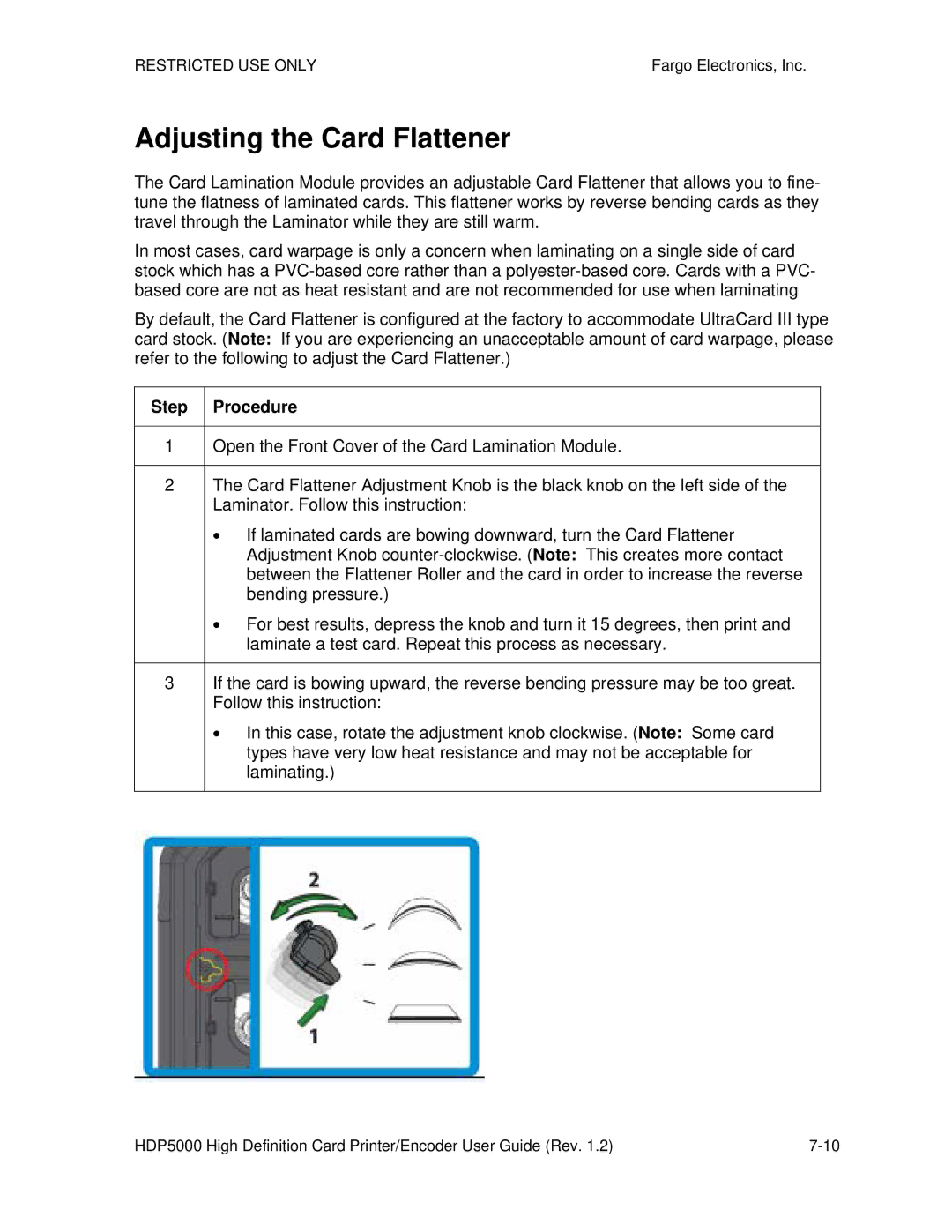

Adjusting the Card Flattener

Printer Adjustments

Printing on Alternate Card Stocks

Selecting the Appropriate HDP Printer Driver settings

Selecting the Appropriate HDP Printer Driver settings

Conducting the Tape Adhesion Test

Conducting the Tape adhesion Test

See the previous

Conducting the Tape adhesion Test

Installing Printer Driver Updates

Printer Driver Options

Installing Printer Driver Updates

When prompted, do not have Windows print a test print

Setting up the Printer

From Disk window will appear

Setting Up the Printer Driver

Setting up Windows 2000/XP/2003

Using the OK, Cancel and Help buttons

Using the Card tab

Use this option to control specific Printer functions

Selecting the Card Size

Selecting the Card Type

Selecting the Card Type

Selecting the Card Type

Please see b on the previous

Setting the Orientation

Specifying the number of Copies

Selecting the Diagnostics button

This will launch the Diagnostic tool if installed

Selecting the Test Print button

Selecting the About button

Selecting the Toolbox button

Using the Device Options tab

This section describes the use of the Device Options tab

Detecting Supplies at Print Time Function

Detecting Supplies at Print Time Function

Detecting Supplies at Print Time Function

Adjusting the Ribbon Type

Use the Ribbon Type dropdown menu to match Ribbon type

Adjusting the Film Type

Using the Dual Sided Group Functions

Using the Dual Sided Print Both Sides option

Step Procedure

Select this option

Backside of the card

Using the Dual Sided Print Back Side Only option

Using the Options Group

Step Procedure

Using the Disable Printing option

Using the Image Color tab

Using the Image Color tab HDP5000

Display B Image Color tab Advanced Image Color window

Using the Quality Color Matching dropdown

Using the Quality Color Matching dropdown

Using the Quality Color Matching dropdown

Using the Quality Color Matching dropdown

Adjusting for the Resin Dither

Using the Advanced Image Color window

Using the Advanced Image Color window

See the previous

Using the Advanced Image Color window

Using the Advanced Image Color window

Using the Advanced Image Color window

Using the Default button on the Image Color tab

Using the Image Transfer tab

Adjusting the Image Position controls

Adjusting the Image Position controls

Adjusting the Transfer Dwell Time and Temperature

Adjusting the Transfer Dwell Time and Temperature

Adjusting the Transfer Dwell Time and Temperature

Adjusting the Transfer Dwell Time and Temperature

Using the Default button

Using the Magnetic Encoding tab

Using the Encoding Mode dropdown list

Category Description

Magnetic Encoding

ISO Encoding

Using the Encoding Mode dropdown list

Category Description Custom Encoding

Category Description Raw Binary

Encoding selection

String rather than a formatted set of characters. Note

Category Description JIS II Encoding

Selecting the Coercivity/Magnetic Track

Reviewing the Shift Data Left Function

Reviewing the Magnetic Track Options

Reviewing the Magnetic Track Options

Using the Magnetic Track Options

Using the Magnetic Track Options

Using the Character Size buttons

Using the Ascii Offset dropdown list

Using the Bit Density dropdown list

Using the LRC Generation dropdown list

Using the Encoding Mode dropdown list

Reviewing the ISO Track Locations

Sending the Track Information

Reviewing the Sample String

Track Start End Field Valid Characters Maximum

Ascii See the table below

Ascii 106 See the table below

Reviewing the Ascii Code and Character Table

Using the Default button Image Transfer tab

Using the Lamination tab HDP5000-LC

Selecting the Lamination Position

Adjusting the Lamination Speed Transfer Dwell Time

Selecting the Lamination Side dropdown menu

No Flipper Single Side Card Lamination Unit Lower

Dual Side Card Lamination Unit

Selecting the Lamination Type

Selecting the Lamination Type

See previous

Adjusting the Lamination Temperature

Default = 145.4 Celsius

Upper Limit = 170.0 Celsius

Lower Limit = 50.0 Celsius

Selecting the Defaults button

Using the K Panel Resin tab

Using the Scroll controls

Controls Description

Using the Click and Drag capability

Using the Add and Delete buttons

Selecting inches or mm radio button

Selecting the Full Card

Selecting the Defined Areas

Selecting the Undefined Areas

Defining the Area to activate the Card Grid

Measuring the Total Card area

Measuring the Area to be positioned on the Card

Selecting the Print YMC under the K and Print K Only options

Selecting the Print YMC under the K and Print K Only options

Using the Printer Supplies tab

Reviewing Information on the Supplies tab

Lamination Cartridge 1 Level Type, Reorder Number and Gauge

Lamination Cartridge 2 Level Type, Reorder Number and Gauge

Relates to the procedure on the previous

Reviewing Information on the Supplies tab

Accessing the Toolbox

This section describes the Toolbox function

Selecting the Configuration tab

Using the Configuration Tab

Using the Optional Printer Features Group Box

Using the Event Monitoring Group Box

Reviewing the Ribbon Low message

Display Ribbon Low dialog

Reviewing the Laminate Low Message

Using the Film Low message

Selecting the Set Language for Printer LCD Display Group Box

Selecting the Calibrate Laminator tab

Calibrate Passed

Selecting the Calibrate Film tab

Selecting the Calibrate Ribbon tab

Selecting the Clean Printer tab

Selecting the Clean Printer tab

See the procedure on the previous

Using the Clean Printer Group Box

Selecting the Advanced Settings tab

Selecting the Advanced Settings tab

Restore Defaults Button Restores default values

Reviewing the No Printer Connected error message

Reviewing the Value outside the Range error message

Cleaning

Using the Required Supplies

Safety Messages review carefully

Accessing the Clean Printer tab

Cleaning the Printer Platen Roller and Card Feed Rollers

Cleaning the Printer Platen Roller and Card Feed Rollers

Cleaning Procedures

Cleaning inside the Printer

Cleaning outside the Printer

Cleaning the Printhead

Replacing the Card Cleaning Roller

Steps Procedure

Cleaning the Magnetic Encoder

Reviewing the Card tab and Diagnostic button

Display a Card tab Diagnostics button

Reviewing the Card tab and Diagnostic button

Clean the Printhead with a Printhead swab

Cloth

Be sure to enclose any necessary paperwork, test cards, etc

Firmware Updates

Performing the Firmware Updates

Performing the Firmware Updates

Using the drop down menu, select the Printer

This will launch the Fargo Support

Click on the Firmware selection box

Click on the Go button, as shown below

Click on the Save button to save the file

Completed

Dialog

Designated files

Step

This completes the Firmware Update process

Contacting Fargo Technical Support

Finding out when a Fargo Card Printer was manufactured

Reading the Serial Numbers on a Fargo Printer

Reviewing Example No Serial Number A1280224

Reviewing Spare Parts Lists

Reviewing Spare Parts List for HDP5000 and HDP5000-LC

Glossary of Terms

Term Definition

Glossary of Terms

Glossary of Terms

Glossary of Terms

Glossary of Terms

Eeprom

Eprom

Glossary of Terms

Glossary of Terms

ISO

Glossary of Terms

Glossary of Terms

Glossary of Terms

PET

PVC

Resin Semi-solid material

RGB

Glossary of Terms

TAC

PVC

Designation of colored Ribbon by the panels of color

Order in which they are printed Yellow Y, Magenta M

Cyan C

Order in which they are printed Yellow Y, Magenta M, Cyan

Index

Embedded contaminants

No MiFare Encoder No Prox Encoder

Scroll controls K Panel

WordPad