2.3 Special Paper

Transparency

Transparencies for overhead projectors must withstand the heat of fusing during the printing process. The recommended transparency product is as follows:

3M CG3700 (Letter, A4)

Transparencies must be placed on the MP

When unloading transparencies (e.g., for clearing jams), hold them carefully by the edges to avoid leaving fingerprints on them.

Adhesive-backed labels

Label paper must be fed manually.

For printing on labels, use extreme care so that the adhesive may not come in direct contact with any part of the printer. Adhesives that stick to the drum or rollers will cause printer damage.

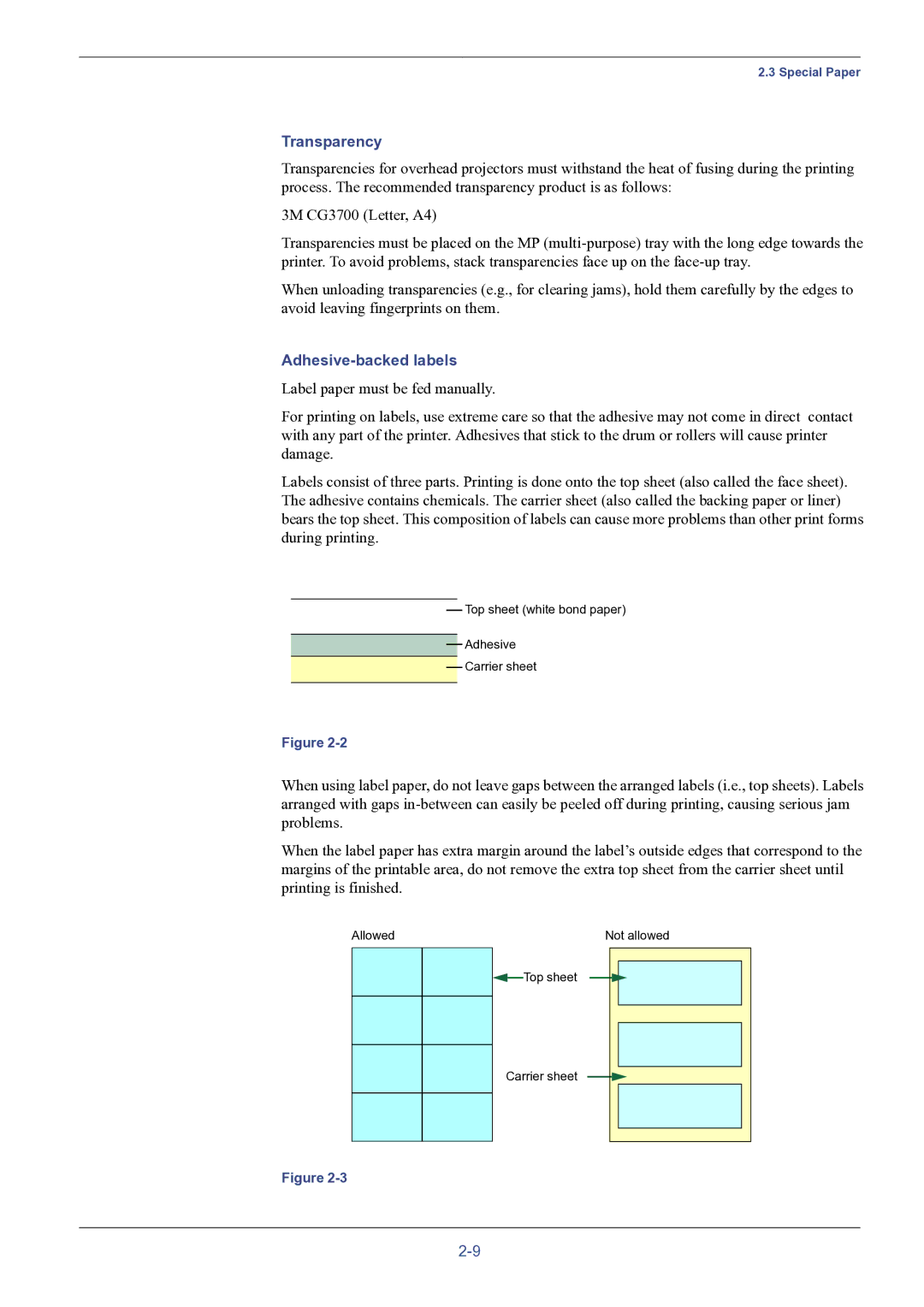

Labels consist of three parts. Printing is done onto the top sheet (also called the face sheet). The adhesive contains chemicals. The carrier sheet (also called the backing paper or liner) bears the top sheet. This composition of labels can cause more problems than other print forms during printing.

Top sheet (white bond paper)

![]() Adhesive

Adhesive

Carrier sheet

Figure

When using label paper, do not leave gaps between the arranged labels (i.e., top sheets). Labels arranged with gaps

When the label paper has extra margin around the label’s outside edges that correspond to the margins of the printable area, do not remove the extra top sheet from the carrier sheet until printing is finished.

Allowed | Not allowed |

![]()

![]() Top sheet

Top sheet

Carrier sheet

Figure