2.3 Special Paper

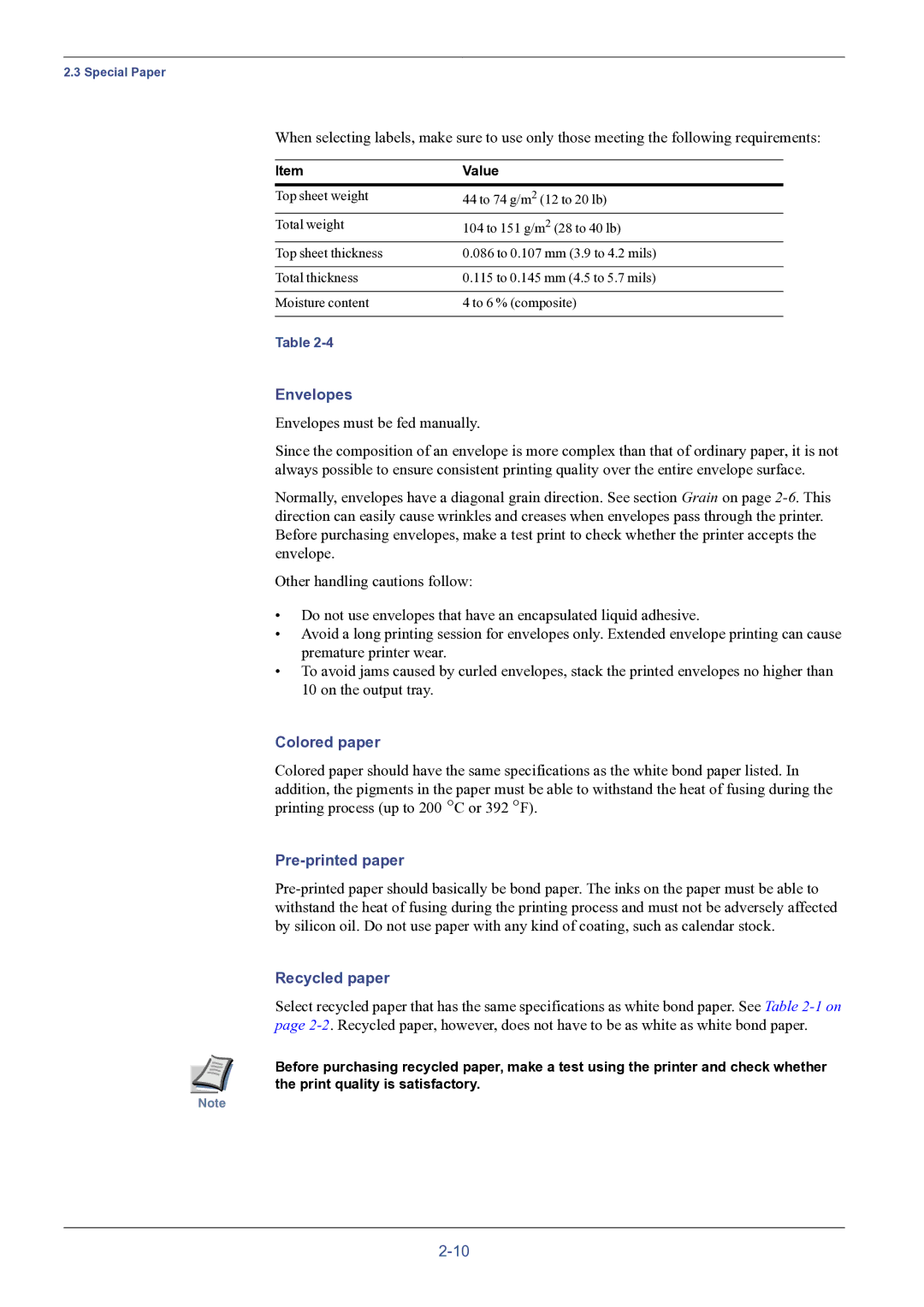

When selecting labels, make sure to use only those meeting the following requirements:

Item | Value |

Top sheet weight | 44 to 74 g/m2 (12 to 20 lb) |

Total weight | 104 to 151 g/m2 (28 to 40 lb) |

Top sheet thickness | 0.086 to 0.107 mm (3.9 to 4.2 mils) |

|

|

Total thickness | 0.115 to 0.145 mm (4.5 to 5.7 mils) |

|

|

Moisture content | 4 to 6 % (composite) |

|

|

Table |

|

Envelopes

Envelopes must be fed manually.

Since the composition of an envelope is more complex than that of ordinary paper, it is not always possible to ensure consistent printing quality over the entire envelope surface.

Normally, envelopes have a diagonal grain direction. See section Grain on page

Other handling cautions follow:

•Do not use envelopes that have an encapsulated liquid adhesive.

•Avoid a long printing session for envelopes only. Extended envelope printing can cause premature printer wear.

•To avoid jams caused by curled envelopes, stack the printed envelopes no higher than 10 on the output tray.

Colored paper

Colored paper should have the same specifications as the white bond paper listed. In addition, the pigments in the paper must be able to withstand the heat of fusing during the printing process (up to 200 °C or 392 °F).

Pre-printed paper

Recycled paper

Select recycled paper that has the same specifications as white bond paper. See Table

Before purchasing recycled paper, make a test using the printer and check whether the print quality is satisfactory.

Note